Introduction

In the world of packaging and manufacturing, heat seal glue is a game changer. This innovative adhesive technology utilizes heat to create strong, durable bonds between materials, making it essential for various applications across industries. From food packaging to medical supplies, understanding the nuances of heat seal technology can significantly enhance efficiency and product integrity.

Understanding Heat Seal Glue

Heat seal glue is a specialized adhesive that activates with heat, allowing for seamless bonding of different substrates. Its composition typically includes polymers that melt when exposed to elevated temperatures, forming a robust seal once cooled. This unique mechanism differentiates it from traditional pressure sensitive adhesives and high temperature adhesives, which rely on different bonding principles.

Applications of Heat Seal Technology

The versatility of heat seal technology is evident in its wide range of applications. It is commonly employed in food packaging to ensure freshness and safety by creating airtight seals that prevent contamination. Additionally, heat sealer medical packaging leverages this technology to maintain sterility and compliance with stringent regulatory standards.

Benefits of Using Heat Seal Adhesives

Using heat seal adhesives offers numerous advantages over other bonding methods. For one, they provide strong bonding capabilities that withstand various environmental conditions without compromising integrity. Moreover, advancements like heat seal coating have introduced eco-friendly options that cater to sustainability concerns while maintaining high performance across different sectors.

What is Heat Seal Glue?

When you hear heat seal glue, think of a magical bonding agent that brings materials together with the power of heat. This specialized adhesive is designed to create strong, durable seals in various applications, from food packaging to medical supplies. Understanding its composition and functionality can help you appreciate why it’s a go-to choice for so many industries.

Definition and Composition

Heat seal glue is a type of adhesive that forms a bond when heat and pressure are applied, making it an essential component in heat seal technology. Typically composed of thermoplastic polymers or resins, this glue can be tailored to meet specific performance requirements such as flexibility, durability, and resistance to environmental factors. The unique formulation allows it to adhere seamlessly to different substrates, ensuring a reliable seal every time.

How Heat Seal Glue Works

The magic behind heat seal glue lies in its ability to soften when exposed to heat, allowing it to flow into the surfaces being bonded. As the temperature rises and pressure is applied through heat sealers for food packaging or other devices, the adhesive penetrates the material's surface for a tight grip. Upon cooling, the glue solidifies again, creating a robust bond that can withstand various stresses—ideal for everything from packaging snacks to medical supplies.

Types of Heat Seal Glue

There are several types of heat seal glue available on the market today, each catering to different needs and applications. For instance, pressure sensitive adhesives offer instant bonding without needing additional heat—perfect for quick fixes or temporary seals. On the other hand, high temperature adhesives are designed specifically for environments where elevated temperatures are common; they excel in applications like heat sealer medical packaging where sterility and resilience are paramount.

The Advantages of Heat Seal Technology

When it comes to modern bonding solutions, heat seal technology stands out for its impressive array of advantages. From eco-friendly options to strong bonding capabilities, heat seal glue is transforming various industries. Let's dive into the specifics that make this technology a game-changer.

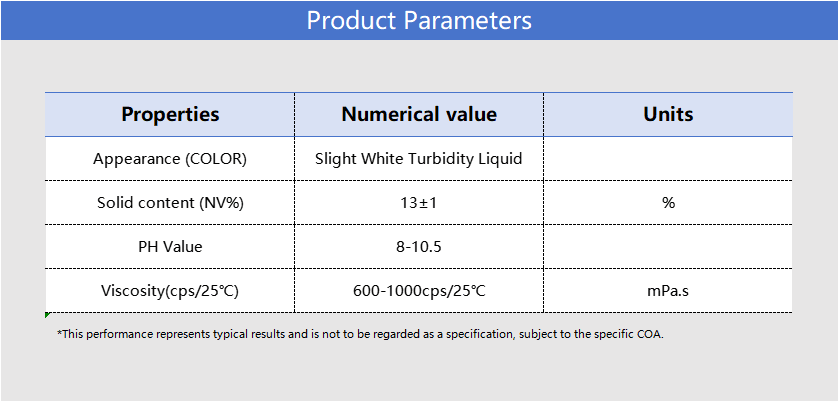

Eco-Friendly Options like Chemix's Water-Based Resin Solution

In an era where sustainability is paramount, Chemix's water-based resin solution exemplifies the eco-friendly options available in heat seal adhesives. Unlike traditional solvents that can be harmful to the environment, this innovative adhesive minimizes volatile organic compounds (VOCs), making it a safer choice for both users and the planet. By opting for such environmentally conscious heat seal glue, businesses can enhance their green credentials while maintaining high performance in applications like food packaging and medical packaging.

Strong Bonding Capabilities

One of the most compelling features of heat seal technology is its strong bonding capabilities, which are essential across various applications. Whether you’re sealing packages for food or ensuring the integrity of medical supplies, high temperature adhesives deliver a robust bond that withstands stress and strain. This reliability means that products sealed with heat seal glue can maintain freshness or sterility longer, reducing waste and increasing customer satisfaction.

Versatility Across Industries

Heat seal technology is not just limited to one sector; its versatility spans numerous industries from food packaging to healthcare. For instance, in food packaging, heat sealers provide airtight seals that keep products fresh and safe for consumption, while in medical applications, they ensure sterility through secure seals with heat sealer medical packaging methods. With pressure sensitive adhesives also playing a role in many applications where quick adhesion is needed without additional equipment, it's clear that heat seal glue has carved out a niche across diverse fields.

Choosing the Right Heat Seal Adhesive

Selecting the right heat seal adhesive can make or break your packaging game. With a plethora of options available, it’s essential to understand the differences between pressure sensitive adhesives and high temperature adhesives. Each type serves distinct purposes in various applications, from food packaging to medical supplies, ensuring that your products remain secure and intact.

Comparing Pressure Sensitive Adhesives and High Temperature Adhesives

Pressure sensitive adhesives (PSAs) are a popular choice for heat seal applications due to their ease of use and versatility. They bond upon application of pressure without requiring any additional heat, making them ideal for quick fixes or low-temperature environments. On the other hand, high temperature adhesives are formulated to withstand elevated temperatures, making them perfect for applications like heat sealer medical packaging where durability is crucial.

When deciding between these two types of heat seal glue, consider the specific requirements of your project. If you need a quick solution that adheres well under moderate conditions, PSAs might be your best bet. However, if you're dealing with extreme temperatures or need a robust bond for heavy-duty materials, high temperature adhesives will likely serve you better.

Key Factors to Consider

When choosing a heat seal adhesive, several factors should guide your decision-making process. First and foremost is the material compatibility; ensure that your chosen adhesive works effectively with the substrates you're sealing—be it plastic films or paper-based materials used in food packaging or medical applications. Additionally, consider environmental factors such as exposure to moisture or chemicals that may affect adhesion over time.

Another critical factor is the intended application environment; for instance, if you're using heat sealers for food packaging where sterility is vital, selecting an adhesive that meets regulatory standards is non-negotiable. Lastly, think about production speed and efficiency; some adhesives cure faster than others which can significantly impact workflow in high-volume settings.

Recommended Products for Various Applications

For those looking into pressure sensitive adhesives suitable for general use in food packaging, products like Chemix's water-based PSAs offer excellent performance while remaining eco-friendly. These are perfect for achieving strong bonds without compromising on safety standards required in food contact situations. In contrast, if you’re venturing into high-temperature scenarios—like those encountered in heat sealer medical packaging—consider products specifically designed to handle such conditions without losing their bonding strength.

For specialized needs like flexible packaging or multi-layer laminates often found in consumer goods and pharmaceuticals, look into specialized formulations that include advanced heat seal coatings designed to enhance performance under challenging conditions. Always consult product specifications and recommendations based on your unique requirements before making a final choice.

Proper Techniques for Using Heat Sealers

Using heat sealers effectively can make a world of difference in ensuring strong and reliable bonds, particularly when working with heat seal glue. Whether you're in food packaging or medical packaging, mastering the techniques of heat sealing will elevate your projects to the next level. Let’s delve into a step-by-step guide, highlight common pitfalls to avoid, and discuss maintenance tips to keep your equipment running smoothly.

Step-by-Step Guide to Heat Sealing

To begin with, gather all necessary materials including your chosen heat seal glue, substrates, and the heat sealer itself. Start by preparing the surfaces that need sealing; they should be clean and dry for optimal adhesion. Next, apply a thin layer of pressure sensitive adhesive or high temperature adhesive if required by your specific application.

Once everything is set up, align the materials properly within the sealer’s jaws and set the appropriate temperature based on the type of material you’re using. It’s crucial to monitor both time and temperature settings as they directly influence bond strength; too little time can lead to weak seals while excessive heat may damage your materials. After sealing, allow adequate cooling time before handling to ensure that the bond has fully formed.

Common Mistakes to Avoid

One of the most prevalent mistakes is not adhering strictly to recommended temperatures for different types of adhesives like heat seal glue or high temperature adhesive—this can result in poor bonding or even material damage. Another common error is neglecting surface preparation; contaminants like dust or grease can severely compromise adhesion quality in applications such as heat sealer medical packaging.

Additionally, improper alignment during sealing is a frequent oversight that can lead to uneven seals or leaks—especially critical in food packaging scenarios where integrity matters most. Always double-check alignment before closing the sealer's jaws and make sure you’re using compatible materials for effective results.

Maintenance Tips for Heat Seal Equipment

To keep your heat sealers performing at their best, regular maintenance is essential. Start by cleaning any residue from previous operations; leftover adhesives can affect future seals negatively if not removed properly. Check heating elements regularly for wear and tear since consistent performance relies on them functioning optimally.

Moreover, inspect all mechanical components periodically; this includes checking for loose screws or damaged parts that may hinder operation efficiency over time. Lastly, consider keeping a log of maintenance activities so you can track when parts were last serviced—this will help ensure longevity for your equipment while minimizing unexpected downtime associated with repairs.

Industry Insights: Heat Seal Medical Packaging

In the realm of medical packaging, heat seal technology plays a pivotal role in ensuring product integrity and safety. The unique properties of heat seal glue make it an essential component for maintaining sterility in medical devices and supplies. By securely sealing packages, manufacturers can prevent contamination and ensure that products remain safe for use.

Importance of Sterility and Safety

When it comes to medical packaging, sterility is non-negotiable. Heat sealers for food packaging may prioritize freshness, but in the medical field, the stakes are much higher—one breach can lead to serious health risks. Utilizing high temperature adhesive options ensures that packages withstand sterilization processes while maintaining their integrity, providing peace of mind to healthcare professionals.

Moreover, effective sealing methods using heat seal glue help in preventing moisture or air ingress that could compromise a sterile environment. This is especially crucial for items such as surgical instruments and implants where contamination could have dire consequences. Thus, prioritizing safety through proper sealing techniques significantly enhances patient outcomes.

Regulatory Standards and Compliance

The medical packaging industry is governed by strict regulatory standards aimed at ensuring product safety and efficacy. Compliance with guidelines from organizations like the FDA or ISO is essential when employing heat seal technology in medical applications. Manufacturers must ensure their heat sealers meet these regulations while using appropriate adhesives like pressure sensitive adhesive or high temperature adhesive that comply with industry standards.

Documentation proving compliance with these regulations is critical during audits and inspections; any failure to adhere can result in significant penalties or product recalls. Therefore, companies need to invest time into understanding the specific requirements related to their products' packaging methods, including how heat seal coating interacts with various materials used in medical settings. This diligence not only protects consumers but also bolsters brand reputation.

Innovations in Heat Seal Coating

Innovation within the world of heat seal coatings has led to remarkable advancements tailored specifically for the medical sector. New formulations are being developed that enhance adhesion properties while still allowing for easy removal when necessary—a critical factor when dealing with sensitive items like bandages or catheters sealed within protective pouches. These innovations ensure that healthcare providers can access products quickly without compromising sterility.

Additionally, advancements are being made towards creating eco-friendly alternatives within this space; manufacturers are increasingly turning towards sustainable materials without sacrificing performance quality associated with traditional heat seal glue options. Such innovations not only address environmental concerns but also align with growing consumer demand for greener solutions across all industries—including healthcare.

As we look ahead, it's clear that continued innovation will be key in shaping the future of heat sealer medical packaging—ensuring both safety and sustainability remain at the forefront of design considerations.

Conclusion

In the fast-paced world of manufacturing and packaging, the importance of heat seal glue cannot be overstated. This versatile adhesive technology not only enhances efficiency but also ensures that products remain secure and intact during transit. As industries continue to evolve, understanding how to leverage heat seal technology will be crucial for staying competitive and meeting consumer demands.

Maximizing Efficiency with Heat Seal Glue

To maximize efficiency with heat seal glue, it’s essential to choose the right type for your specific application, whether that’s a pressure sensitive adhesive or a high temperature adhesive. Each type brings unique benefits; for instance, pressure sensitive adhesives are great for quick applications while high temperature adhesives offer durability under extreme conditions. Proper training in using heat sealers for food packaging or medical applications can further streamline processes, reduce waste, and improve overall output.

Future Trends in Heat Seal Technology

The future of heat seal technology looks promising with ongoing innovations such as advanced heat seal coating formulations that enhance performance and eco-friendliness. Companies are increasingly focusing on sustainable options like water-based solutions, which cater to both environmental concerns and regulatory compliance in industries like medical packaging. Additionally, automation is set to play a significant role in optimizing the use of heat sealers, making them even more efficient and user-friendly.

Getting Started with Heat Seal Applications

Getting started with heat seal applications requires a thorough understanding of your specific needs and the types of adhesives available—whether you lean towards pressure sensitive adhesives or high temperature adhesives depends on your project requirements. Investing time in learning proper sealing techniques can prevent common mistakes that lead to product failures or safety issues in areas like heat sealer medical packaging. With the right knowledge and tools at hand, embracing this technology can lead to significant improvements in product integrity and customer satisfaction.