Introduction

In a world where sticking things together is often taken for granted, pressure sensitive adhesives have emerged as unsung heroes in various industries. These versatile substances provide a unique bonding solution that requires only the application of light pressure to adhere, making them essential for everything from packaging to automotive applications. As businesses seek reliable pressure sensitive adhesive suppliers, understanding the nuances of these adhesives becomes paramount.

Understanding Pressure Sensitive Adhesives

Pressure sensitive adhesives (PSAs) are defined by their ability to bond materials without the need for heat or solvents, relying solely on pressure to create an effective seal. This functionality allows them to be used in a myriad of applications, including medical devices, consumer goods, and industrial products. With various types available—ranging from rubber-based to acrylic formulations—pressure adhesive tape has become a staple in both manufacturing and everyday life.

The Role of Chemix in the Industry

Enter Chemix: a leading player among adhesive manufacturers dedicated to delivering high-quality solutions tailored to meet diverse customer needs. With an unwavering commitment to innovation and quality, Chemix stands out as a trusted supplier that not only understands the intricacies of pressure sensitive adhesives but also excels in providing cutting-edge products like hot melt adhesives. By choosing Chemix as your supplier, you align yourself with a brand known for its reliability and expertise in creating superior adhesive solutions.

Benefits of Choosing the Right Manufacturer

Selecting the right manufacturer can significantly impact your operations and product quality; this is especially true when it comes to pressure sensitive adhesive suppliers like Chemix. A reputable manufacturer ensures consistency in product performance while offering comprehensive support throughout your project lifecycle—from initial consultation through delivery and beyond. Furthermore, partnering with established adhesive manufacturers means you gain access to innovative technologies that can enhance your product's performance and sustainability.

What Are Pressure Sensitive Adhesives?

Pressure sensitive adhesives (PSAs) are a unique category of adhesives that bond when pressure is applied, without the need for heat or solvents. These versatile compounds are designed to adhere to various surfaces and can be removed without leaving a sticky residue, making them ideal for temporary applications. Understanding the functionality of PSAs is crucial for anyone looking to work with adhesive manufacturers or suppliers in this field.

Definition and Functionality

At their core, pressure sensitive adhesives are formulated to create a bond through simple pressure application. This means that when you press the adhesive against a surface, it sticks—no additional heat or curing time required! This straightforward mechanism makes PSAs incredibly user-friendly and suitable for a wide range of applications, from crafting to industrial uses.

Types of Pressure Sensitive Adhesives

There are several types of pressure sensitive adhesives available on the market today, each tailored for specific needs. Acrylic-based PSAs offer excellent UV resistance and durability, while rubber-based options provide superior tackiness and adhesion strength. Understanding these variations helps consumers choose the right products from reputable pressure sensitive adhesive suppliers based on their requirements.

Applications in Various Industries

Pressure sensitive adhesives find their way into an astonishing array of industries—from automotive to healthcare—demonstrating their versatility and effectiveness. In packaging, they secure labels and seals; in electronics, they hold components together; while in construction, they bond insulation materials efficiently. The breadth of applications showcases why businesses should consider investing in quality products from trusted adhesive manufacturers who specialize in pressure adhesive tape solutions.

Why Choose Chemix as Your Supplier?

When it comes to selecting a supplier for pressure sensitive adhesives, Chemix stands out in a crowded market. Their reputation is built on years of delivering reliable and innovative adhesive solutions that meet the diverse needs of various industries. As one of the leading pressure sensitive adhesive suppliers, Chemix has garnered trust and loyalty from customers who value quality and performance.

Reputation in the Market

Chemix has established itself as a reputable name among adhesive manufacturers, known for its unwavering commitment to excellence. The company’s long-standing presence in the industry reflects its ability to adapt and evolve with changing market demands, ensuring that their pressure adhesive tape solutions remain at the forefront of technology. Customers often cite Chemix's reliability and integrity as key reasons for their continued partnership, making it a preferred choice among pressure sensitive adhesive suppliers.

Commitment to Quality and Innovation

At Chemix, quality isn't just a buzzword—it's a core principle that drives everything they do. Their commitment to innovation means they are always exploring new formulations and technologies to enhance their product offerings, especially in areas like hot melt adhesives. By investing in research and development, Chemix ensures that their pressure sensitive adhesives not only meet but exceed industry standards, providing customers with superior performance.

Comprehensive Product Range

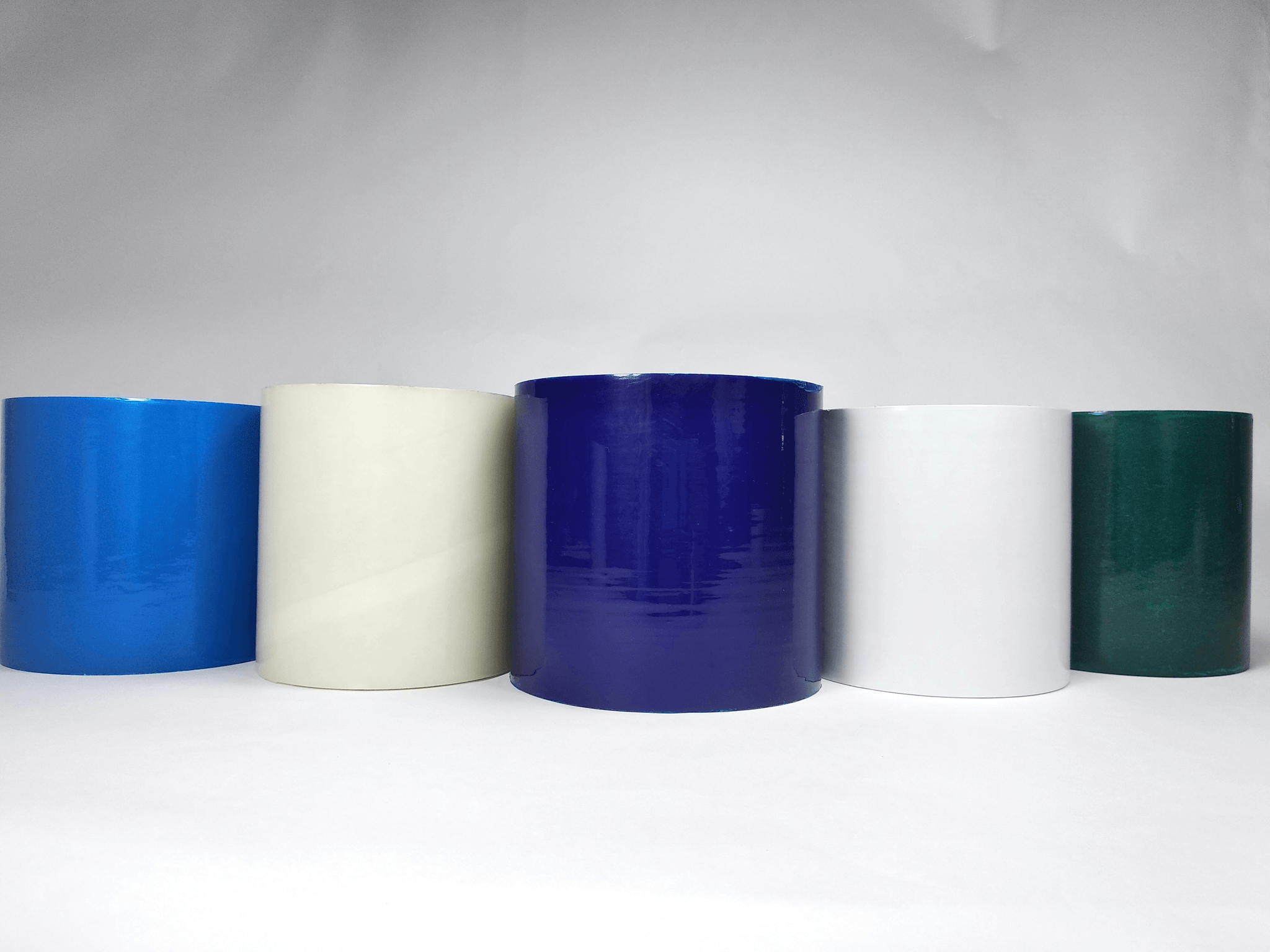

One of the standout features of Chemix is its extensive range of products designed to cater to various applications across multiple industries. Whether you're looking for high-performance pressure sensitive adhesives or specialized hot melt adhesive solutions, Chemix has you covered with an impressive catalog that meets diverse needs. This comprehensive product range makes them a go-to supplier for businesses seeking reliable products from trusted pressure sensitive adhesive suppliers.

Exploring Pressure Adhesive Tape Solutions

In the world of adhesive applications, pressure adhesive tape has carved out a significant niche. These versatile tapes are not only user-friendly but also boast a wide array of uses across various industries. From packaging to electronics, pressure sensitive adhesives play a vital role in ensuring products stay securely bonded while maintaining ease of application.

Common Uses in Everyday Products

Pressure adhesive tape finds its way into many everyday products that we often take for granted. Whether it's the tape holding together your favorite snack packaging or the double-sided tape securing artwork on your walls, these solutions are everywhere. In addition to household items, industries such as automotive and construction rely heavily on pressure sensitive adhesives for bonding components and ensuring durability.

Advantages Over Traditional Adhesives

When comparing pressure sensitive adhesives to traditional adhesives, several advantages come to light. For starters, pressure adhesive tapes offer instant adhesion without the need for drying time or additional curing processes—ideal for fast-paced production environments! Furthermore, they provide consistent performance across various temperatures and conditions, making them a reliable choice for manufacturers looking to streamline their operations.

Choosing the Right Tape for Your Needs

Selecting the right pressure adhesive tape can seem daunting with so many options available from different adhesive manufacturers. However, understanding your specific requirements can simplify this process significantly. Consider factors such as adhesion strength, temperature resistance, and application method when evaluating various products from pressure sensitive adhesive suppliers; this will ensure you find the perfect fit tailored to your needs.

The Significance of Hot Melt Adhesives

Hot melt adhesives play a vital role in various applications due to their unique properties and ease of use. Unlike traditional adhesives, which require solvents or curing agents, hot melt adhesives are solid at room temperature and become liquid when heated. This characteristic allows for quick bonding processes, making them a favorite among pressure sensitive adhesive suppliers and manufacturers looking to optimize production efficiency.

How Hot Melt Adhesives Work

Hot melt adhesives work on the principle of thermoplasticity, meaning they can be melted and re-solidified without significant chemical change. When heated, these adhesives become tacky and can bond to a variety of substrates upon cooling. This rapid setting time is particularly advantageous in high-speed manufacturing environments where pressure adhesive tape is often employed for its reliability and strength.

The versatility of hot melt adhesives also extends to their formulation; they can be tailored with various additives to enhance properties like flexibility, adhesion strength, and resistance to environmental factors. Whether you need an adhesive that withstands extreme temperatures or one that offers superior clarity for aesthetic applications, hot melts can be formulated to meet those demands. This adaptability makes them an essential choice among adhesive manufacturers who prioritize innovation.

Industries Benefiting from Hot Melt Solutions

Numerous industries reap the benefits of hot melt solutions due to their efficiency and performance characteristics. The packaging sector is a prime user; hot melts are frequently utilized for sealing boxes, attaching labels, and securing product components because they provide strong bonds quickly without lengthy drying times. Similarly, the woodworking industry relies heavily on hot melt adhesives for laminating surfaces or assembling furniture components swiftly.

Additionally, the automotive industry has embraced hot melts for their ability to bond materials such as plastics and metals effectively while maintaining structural integrity under stress conditions. Electronics manufacturers also benefit from these adhesives due to their excellent thermal stability and electrical insulation properties—making them ideal for assembling circuit boards without compromising functionality. As you can see, diverse sectors depend on reliable pressure sensitive adhesive suppliers who understand the nuances of these applications.

Comparing Hot Melt and Pressure Sensitive Adhesives

When comparing hot melt adhesives with pressure sensitive adhesives (PSAs), it's essential to note their distinct functionalities suited for different needs. While PSAs are designed to be tacky at room temperature—allowing easy repositioning—they typically require sustained pressure during application for optimal adhesion. In contrast, hot melts offer immediate bonding capabilities upon cooling but may not allow repositioning once set.

Another key difference lies in durability; hot melts often provide stronger bonds in demanding environments compared to PSAs that might degrade under moisture or heat over time. However, PSAs shine in applications requiring convenience and ease-of-use—such as creating removable labels or temporary fixtures with pressure adhesive tape options available in various widths and strengths tailored by leading adhesive manufacturers.

Ultimately, choosing between these two types depends on your specific requirements—whether you're looking for lasting strength or quick application flexibility will guide your decision toward either category's advantages.

Chemix's Water-Based Resin Solution

In the ever-evolving world of adhesives, Chemix stands out with its innovative water-based resin solutions. These resins are gaining popularity among pressure sensitive adhesive suppliers due to their unique advantages and eco-friendly attributes. By choosing water-based options, manufacturers can meet diverse industry needs while promoting sustainable practices.

Advantages of Water-Based Resins

Water-based resins offer numerous benefits that make them a preferred choice for many applications. First and foremost, they provide excellent adhesion properties without compromising on performance, making them ideal for pressure adhesive tape solutions. Additionally, these resins dry quickly and can be formulated to suit various substrates, ensuring versatility across multiple industries.

Moreover, water-based resins are non-toxic and emit fewer volatile organic compounds (VOCs) compared to traditional solvents or hot melt adhesives. This not only enhances safety in manufacturing environments but also aligns with the growing demand for environmentally friendly products. With their ability to deliver high-quality results while minimizing health risks, it's no wonder that pressure sensitive adhesive suppliers are increasingly adopting these innovative solutions.

Environmental Impact and Sustainability

The environmental impact of adhesives has become a significant concern in recent years, prompting many adhesive manufacturers to seek greener alternatives. Chemix's water-based resin solutions stand out as a sustainable option that reduces harmful emissions during production and application processes. By utilizing these resins, companies can significantly decrease their carbon footprint while still achieving superior performance in their adhesive products.

Furthermore, the use of water as a solvent not only lessens environmental harm but also simplifies cleanup processes for manufacturers using pressure sensitive adhesives. This ease of maintenance translates into lower operational costs and increased efficiency in production lines—an attractive proposition for businesses looking to enhance sustainability without sacrificing quality or effectiveness.

Versatility in Applications

One of the most compelling aspects of Chemix's water-based resin solution is its versatility across various applications and industries. From packaging materials to automotive components, these resins can be tailored to meet specific requirements while maintaining strong adhesion properties essential for pressure adhesive tape products. Their adaptability makes them an invaluable resource for businesses seeking reliable bonding solutions without being limited by material compatibility.

Additionally, the flexibility offered by water-based resins allows manufacturers to develop customized formulations that cater specifically to their end-use applications—whether it’s creating durable labels or crafting specialized tapes used in construction projects. As more industries turn towards sustainable practices, integrating versatile products like Chemix's water-based resins becomes critical for staying competitive in today's market.

Conclusion

In the ever-evolving world of adhesives, choosing quality pressure sensitive adhesives is paramount for success in various applications. Not only do these adhesives provide reliable bonding solutions, but they also enhance product performance across different industries. By opting for reputable pressure sensitive adhesive suppliers like Chemix, businesses can ensure they are backed by innovation and quality.

Choosing Quality Pressure Sensitive Adhesives

When selecting pressure sensitive adhesives, it's essential to consider their functionality and compatibility with your specific needs. High-quality pressure adhesive tape can significantly impact the durability and effectiveness of your products, whether in packaging, automotive, or electronics. By doing thorough research and partnering with trusted adhesive manufacturers, you can find the right adhesive solution that meets your demands.

Key Benefits of Chemix Products

Chemix stands out among pressure sensitive adhesive suppliers due to its unwavering commitment to quality and innovation. Their comprehensive product range includes not only top-tier pressure sensitive adhesives but also cutting-edge hot melt adhesives designed for various applications. With a focus on customer satisfaction and tailored solutions, choosing Chemix products ensures you receive both reliability and performance.

Future Trends in Adhesive Manufacturing

As we look ahead in the adhesive manufacturing landscape, several trends are shaping the future of pressure sensitive adhesives. Sustainability is becoming increasingly important; thus, many manufacturers are focusing on eco-friendly options such as water-based resins that minimize environmental impact while maintaining high performance. Additionally, advancements in technology may lead to smarter adhesive solutions that offer enhanced functionalities—making it an exciting time to be involved with innovative pressure sensitive adhesive suppliers.