Introduction

In the ever-evolving world of packaging, understanding laminating adhesives is crucial for creating effective and sustainable solutions. These adhesives serve as the backbone of packaging laminates, enhancing both functionality and aesthetic appeal. With a wide range of applications, from food preservation to industrial uses, laminated packaging has become a cornerstone in various sectors.

Understanding Laminating Adhesives

Laminating adhesives are specialized substances designed to bond multiple layers of materials together, creating a composite structure known as laminates. These adhesives can significantly improve the durability and barrier properties of packaging materials.

Importance in Packaging Solutions

The importance of laminating adhesives cannot be overstated; they play a vital role in extending shelf life and maintaining product integrity. In an industry where first impressions matter, using high-quality packaging laminates can elevate brand perception and consumer trust. Moreover, these solutions often meet stringent industry standards that govern safety and sustainability.

Overview of Product Applications

Laminated packaging examples abound across various industries—from snack foods wrapped in vibrant films to medical supplies securely housed in protective layers. Each application showcases the versatility of lamination techniques tailored to specific needs, whether that’s moisture resistance or enhanced visual appeal. As we explore the landscape of types of lamination in packaging, it becomes clear that innovation drives progress in this field.

What Are Laminates in Food Packaging

Laminates play a crucial role in the food packaging industry, serving as a barrier between the product and external elements. Essentially, they are composite materials made by bonding together multiple layers of different substances to create a single functional unit. This multi-layered approach not only enhances the structural integrity of the packaging but also optimizes its performance in preserving food quality.

Definition and Purpose

In the realm of food packaging, laminates refer to materials that combine various substrates—such as plastic films, paper, or aluminum foil—through processes like heat sealing or adhesive bonding. The primary purpose of these packaging laminates is to protect food products from moisture, oxygen, and light while also extending shelf life. By utilizing different types of lamination in packaging, manufacturers can tailor their products to meet specific preservation needs and consumer preferences.

Benefits for Food Preservation

The benefits of using laminated packaging are numerous and significant for food preservation. For starters, these laminates create an effective barrier that prevents spoilage due to environmental factors like humidity or air exposure, thereby maintaining freshness longer. Additionally, laminated packages often have improved mechanical strength and puncture resistance compared to single-layer alternatives, making them ideal for transporting delicate items without compromising quality.

Industry Standards and Regulations

Regulatory bodies such as the FDA set stringent guidelines regarding materials used in food contact applications to ensure safety for consumers. Manufacturers must adhere to these regulations while also considering sustainability practices; thus balancing innovation with responsibility is key when developing new laminated packaging solutions that meet both market demands and regulatory requirements.

Types of Lamination in Packaging

The choice between flexible and rigid lamination can significantly impact both functionality and aesthetics. Additionally, knowing when to use cold or hot lamination techniques can enhance the durability and visual appeal of your laminated packaging examples.

Flexible vs. Rigid Lamination

Flexible lamination involves materials that can bend and conform to various shapes, making it ideal for products like pouches or wraps. This type of packaging laminates is commonly used in food packaging because it provides a tight seal that protects contents from moisture and air exposure, thereby extending shelf life. On the flip side, rigid lamination is utilized for items requiring structural integrity, such as boxes or containers; it offers stability while still preserving product quality.

The choice between flexible and rigid options often boils down to the specific requirements of the product being packaged. For instance, if you're dealing with snacks or perishable goods, flexible laminates are generally preferred due to their superior sealing properties. However, if you need something sturdier for shipping or retail display, rigid laminates will serve you better.

Cold vs. Hot Lamination Techniques

When discussing types of lamination in packaging, one must also consider cold versus hot lamination techniques—each with its unique advantages and applications. Cold lamination uses pressure-sensitive adhesives that bond materials together without heat; this method is often favored for sensitive items that could be damaged by high temperatures during processing. It’s an excellent choice for laminated packaging examples where temperature control is crucial.

Conversely, hot lamination involves applying heat to activate adhesives; this technique creates a strong bond suitable for high-volume production runs where durability is paramount. Hot laminated products tend to have a glossy finish which enhances presentation—a vital factor in consumer-driven markets like food and beverage packaging. Ultimately, deciding between these two techniques hinges on factors such as production speed requirements and material sensitivity.

Choosing the Right Type

Selecting the right type of laminate can feel overwhelming given the variety available in today’s market—but fear not! Start by evaluating your specific needs based on what are laminates in food packaging: Is moisture resistance critical? Will your product require flexibility? These questions will guide you toward either flexible or rigid options.

Next up: consider whether cold or hot lamination aligns better with your production capabilities and material compatibility—this step ensures that your chosen method won’t compromise product integrity or lead to costly errors down the line. Lastly, always keep an eye on industry trends; innovations may introduce new materials or methods that could elevate your laminated packaging examples beyond traditional solutions.

Laminated Packaging Examples

Laminated packaging is a versatile solution that spans across various industries, showcasing the adaptability of packaging laminates. From food products to consumer goods, laminated packaging examples illustrate how these materials enhance shelf life and product appeal. In this section, we will explore common uses in different sectors, delve into case studies that highlight successful applications, and examine innovative designs and technologies transforming the landscape of laminated packaging.

Common Uses in Various Industries

Packaging laminates are widely utilized in the food industry to ensure freshness and extend shelf life. For instance, snack foods often employ laminated films that provide moisture barriers while being visually appealing on store shelves. Beyond food, laminated packaging examples can be found in pharmaceuticals where protective layers keep medications safe from environmental factors.

In the cosmetics sector, brands leverage laminated tubes for their aesthetic appeal and durability, making them popular among consumers who value both function and design. Additionally, household products like detergents utilize laminated pouches to prevent leakage while maintaining a lightweight package for ease of use. The versatility of types of lamination in packaging allows manufacturers to tailor solutions that meet specific product requirements across diverse industries.

Case Studies of Successful Applications

One standout example involves a leading snack manufacturer that transitioned to using advanced laminated films for their potato chips. By adopting high-performance packaging laminates with enhanced barrier properties, they successfully reduced product spoilage during transportation while boosting sales through eye-catching graphics on the packages. This shift not only improved customer satisfaction but also demonstrated how effective laminated packaging examples can drive business success.

Another compelling case study comes from a beverage company that implemented eco-friendly laminates made from recyclable materials for their juice cartons. This move not only aligned with growing consumer demand for sustainable practices but also met stringent industry regulations regarding food safety and environmental impact. The success of these applications underscores the importance of selecting suitable types of lamination in packaging to achieve both functionality and marketability.

Innovative Designs and Technologies

Innovative designs in laminated packaging are evolving rapidly as technology advances continue to reshape the industry landscape. For instance, smart laminates embedded with sensors can monitor freshness levels or detect tampering—an exciting development that enhances consumer trust while providing real-time data for manufacturers. These cutting-edge solutions illustrate how what are laminates in food packaging can go beyond traditional uses by integrating technology into everyday products.

Moreover, advancements in printing techniques allow for intricate graphics and textures on laminate surfaces that captivate consumers' attention at first glance. Brands are increasingly utilizing holographic effects or matte finishes to create visually striking packages that stand out on crowded shelves—demonstrating how aesthetics play a crucial role alongside functionality in packaged goods today. As we look ahead, it’s clear that continued innovation will redefine what we know about laminated packaging examples across all sectors.

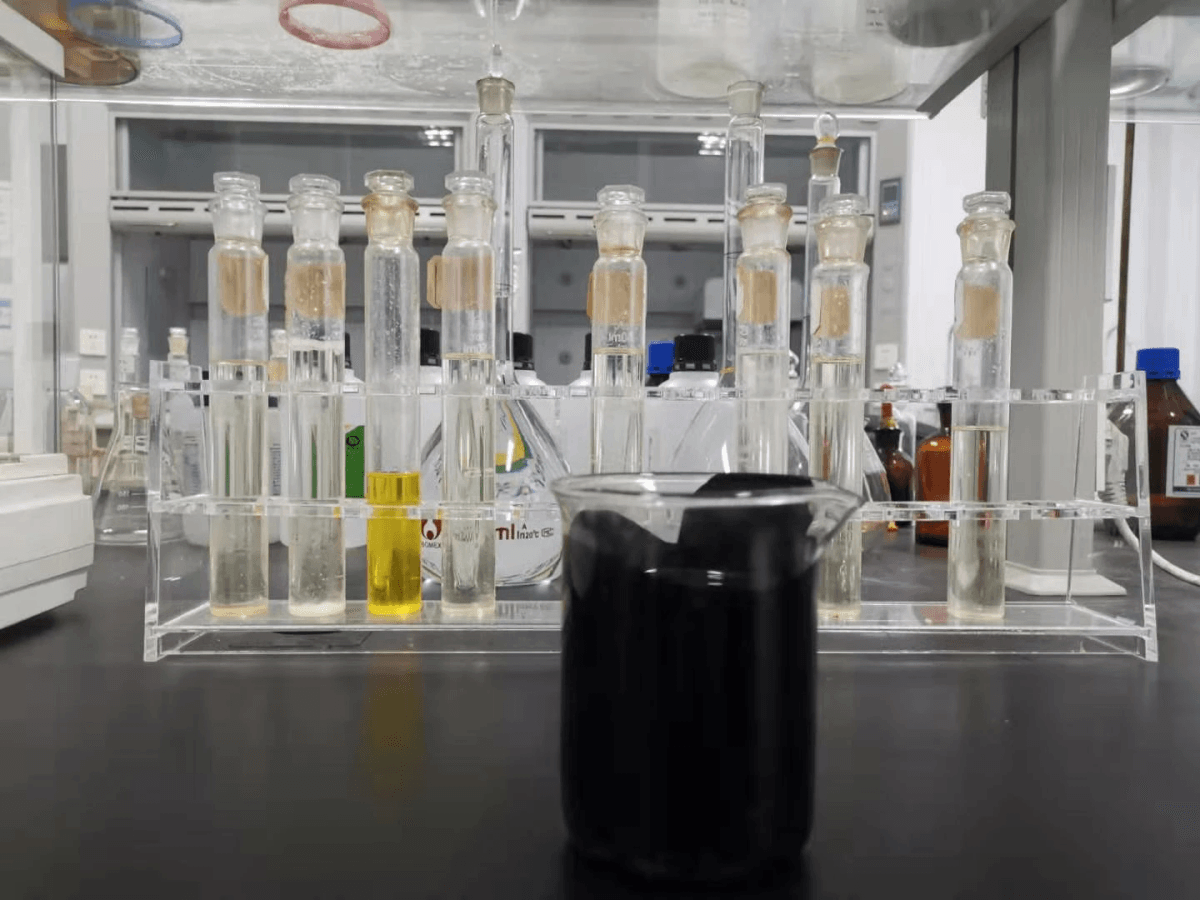

Exploring Chemix's Water-Based Resin Solution

Chemix's water-based resin solution is revolutionizing the world of packaging laminates, offering a range of features that cater to modern demands. Unlike traditional solvent-based adhesives, these resins are designed with user safety and environmental consciousness in mind. Their versatility makes them suitable for various applications, from food packaging to industrial uses, enhancing the durability and performance of laminated packaging examples.

Features and Benefits of Water-Based Resin

One of the standout features of Chemix's water-based resin is its strong adhesion properties, which ensure that laminated packaging remains intact under various conditions. This type of adhesive also boasts quick drying times, allowing for faster production cycles—an essential factor in today’s fast-paced market. Furthermore, water-based resins offer excellent clarity and flexibility, making them ideal for a wide array of packaging laminates without compromising on aesthetics or functionality.

Environmental Impact and Sustainability

When it comes to environmental impact, Chemix’s water-based resin shines brightly against its solvent counterparts. These resins are formulated with fewer volatile organic compounds (VOCs), meaning they contribute less to air pollution during application. By choosing these sustainable options in laminated packaging examples, companies can significantly reduce their carbon footprint while meeting stringent industry regulations regarding eco-friendliness.

Applications Across Multiple Industries

The versatility of Chemix's water-based resin extends across multiple industries beyond just food packaging; it plays a crucial role in creating durable labels and protective films as well. From consumer goods to electronics and pharmaceuticals, this innovative solution adapts seamlessly to various types of lamination in packaging needs. As businesses increasingly prioritize sustainability alongside performance, the demand for such adaptable solutions continues to grow exponentially.

Key Considerations for Selecting Laminating Adhesives

When it comes to selecting the right laminating adhesives for your packaging needs, several key factors come into play. Understanding the specific requirements of your project is essential, as different applications may call for different types of adhesives. Whether you’re working with flexible or rigid materials, the choice can significantly impact the performance and functionality of your packaging laminates.

Factors to Evaluate When Choosing Adhesives

First and foremost, consider the end-use application of your packaging laminates. Are they intended for food packaging or industrial use? The nature of the product being packaged will determine whether you need a high-performance adhesive that can withstand various environmental conditions or a more standard option. Additionally, factors such as drying time, adhesion strength, and resistance to moisture or chemicals should also be evaluated.

Another important consideration is regulatory compliance; especially when discussing what are laminates in food packaging. The adhesive must meet industry standards and regulations to ensure safety and effectiveness in preserving food products. Lastly, cost-effectiveness should not be overlooked; balancing quality with budget constraints is crucial in making an informed decision.

Performance Metrics and Testing

Once you have identified potential adhesives based on your project’s needs, it’s time to dive into performance metrics and testing procedures. Look for data on peel strength, shear strength, and tensile strength; these metrics will give you insight into how well the adhesive will perform under various conditions. Conducting tests on laminated packaging examples can help evaluate how these adhesives react when subjected to real-world scenarios.

Moreover, consider conducting accelerated aging tests to assess long-term performance over time—an essential step when evaluating types of lamination in packaging that may face wear and tear during storage or transport. This rigorous testing ensures that your chosen adhesive will maintain its integrity throughout its lifecycle.

Compatibility with Various Materials

Compatibility is another critical factor when selecting laminating adhesives for your packaging needs. Not all adhesives work well with every substrate; therefore, knowing which materials you’ll be using is vital in ensuring optimal bonding effectiveness within your laminated structures. For instance, if you're working with biodegradable films or specialized coatings often used in sustainable packaging solutions, it's important to select an adhesive designed specifically for those materials.

Furthermore, understanding how different types of lamination in packaging interact with each other can help prevent issues like delamination during production processes or end-use applications. A thorough compatibility analysis ensures that both the adhesive and substrates work harmoniously together—ultimately leading to improved product durability and performance.

Conclusion

In wrapping up our exploration of packaging laminates, it’s clear that these materials play a pivotal role in modern packaging solutions. From enhancing food preservation to offering innovative designs, the importance of laminating adhesives cannot be overstated. As industries evolve, so too do the technologies and methodologies surrounding what are laminates in food packaging and beyond.

Future Trends in Laminating Adhesives

The future of laminating adhesives is poised for exciting developments, particularly with advancements in technology and sustainability. We can expect to see a surge in the use of eco-friendly materials that align with consumer preferences for greener products. Additionally, innovations such as smart packaging solutions will likely integrate seamlessly with various types of lamination in packaging, enhancing functionality while maintaining aesthetic appeal.

Innovations in Sustainable Packaging

Sustainable packaging is no longer just a trend; it's becoming a necessity as consumers demand more environmentally responsible options. Innovations like biodegradable laminates and recyclable adhesive solutions are paving the way for a cleaner future. Companies that embrace these changes not only contribute to environmental goals but also position themselves favorably within competitive markets by utilizing cutting-edge laminated packaging examples that resonate with eco-conscious consumers.

Final Thoughts on Packaging Laminates

In summary, understanding what are laminates in food packaging and their applications across various industries is crucial for anyone involved in product development or marketing. The versatility offered by different types of lamination in packaging enables businesses to meet diverse needs while ensuring quality and durability. As we look ahead, it’s evident that embracing new technologies and sustainable practices will shape the landscape of packaging laminates for years to come.