Introduction

In today's fast-paced world, adhesives have become indispensable tools across various industries, driving innovation and efficiency. Among these, automotive adhesives stand out for their unique properties and applications, revolutionizing how vehicles are manufactured and assembled. With the growing demand for lightweight and durable materials in the automotive sector, understanding the role of adhesives used in the automotive industry is more crucial than ever.

The World of Adhesives

The adhesive market is a dynamic landscape filled with diverse products tailored to meet specific needs across multiple sectors. From construction to aerospace, adhesives serve as critical bonding agents that enhance structural integrity while reducing weight—a vital consideration in modern engineering. In this realm, automotive structural adhesive solutions are particularly noteworthy due to their ability to withstand harsh conditions while maintaining performance.

Exploring Automotive Adhesives

Automotive adhesives encompass a range of products designed specifically for vehicle manufacturing and repair processes. These adhesives not only bond components but also contribute to overall vehicle safety and performance by providing flexibility and strength where needed most. Structural adhesive bonding techniques have become increasingly popular in the automotive industry, allowing for seamless integration of materials that traditional methods may struggle to achieve.

Key Players in Adhesive Manufacturing

The adhesive manufacturing sector features several key players who have established themselves as leaders through innovation and quality. Companies like Henkel, 3M, and Sika have paved the way in developing advanced adhesive solutions tailored for automotive applications. Their commitment to research and development ensures that they continue to provide cutting-edge products that meet the evolving demands of the automotive adhesives market.

What Are Adhesives?

Adhesives are substances used to bond materials together, providing strength and durability in various applications. They come in a variety of types, each designed for specific uses and conditions. In the automotive sector, adhesives play a crucial role in enhancing vehicle performance and safety.

Definition and Types

At their core, adhesives are materials that create a bond between surfaces through various mechanisms such as chemical reactions or physical adhesion. The types of adhesives range from simple glue sticks to complex structural adhesive automotive solutions that can withstand extreme conditions. Common categories include pressure-sensitive adhesives, epoxies, polyurethanes, and water-based resins—each serving unique purposes in industries like construction, aerospace, and particularly the automotive industry.

Importance in Various Industries

In numerous industries, adhesives are essential for manufacturing processes and product integrity. They help reduce weight in structures while maintaining strength—an important factor in sectors like aerospace and automotive where every ounce counts. Moreover, the versatility of adhesives allows for innovative designs that enhance functionality across products ranging from electronics to furniture.

Adhesives Used in Automotive Industry

The automotive industry extensively utilizes various types of adhesives to improve vehicle assembly and performance. Automotive adhesives include sealants for weatherproofing joints as well as structural adhesive bonding agents that provide critical support to components under stress. Notably, automotive structural adhesive solutions contribute significantly to vehicle safety by ensuring parts remain securely attached during operation while also aiding in noise reduction and thermal insulation.

The Role of Automotive Adhesives

Automotive adhesives play a crucial role in modern vehicle manufacturing, significantly influencing safety, performance, and aesthetics. These specialized adhesives are designed to bond different materials together, ensuring that vehicles are not only durable but also lightweight and fuel-efficient. As the automotive industry continues to evolve, understanding the various types of adhesives used in automotive applications is essential for manufacturers aiming to stay ahead.

Different Types of Automotive Adhesives

When it comes to automotive adhesives, variety is the name of the game. You have your epoxies, polyurethanes, acrylics, and even silicone-based options—all tailored for specific bonding needs within vehicles. Each type has unique properties that make it suitable for different applications; for instance, structural adhesive bonding is often employed in critical areas where strength and durability are paramount.

In addition to these traditional types, advancements in adhesive technology have led to the development of hybrid adhesives that combine characteristics from multiple types for enhanced performance. This innovation allows manufacturers to select an adhesive automotive solution that best meets their requirements—whether that's flexibility for trim or rigidity for structural components. The right choice can make a world of difference in both assembly efficiency and long-term vehicle integrity.

Benefits of Using Adhesives in Vehicles

The benefits of using automotive adhesives extend far beyond mere convenience; they can dramatically improve vehicle performance and safety too. For starters, adhesive bonding techniques often result in lighter vehicles since they allow manufacturers to use thinner materials without sacrificing strength—a key factor as fuel efficiency becomes increasingly important. Additionally, these adhesives help reduce noise and vibration inside vehicles by dampening sound transmission between parts.

Another significant advantage is the increased design freedom they offer engineers and designers alike. With traditional mechanical fasteners like bolts or rivets, there are limitations on how materials can be joined together; however, with automotive structural adhesive solutions, complex shapes can be bonded seamlessly without compromising aesthetics or functionality. This flexibility allows for more innovative designs that enhance both form and function.

Structural Adhesives and Their Applications

Structural adhesives are particularly noteworthy within the realm of automotive applications due to their exceptional bonding capabilities under stress conditions—think crash scenarios or heavy loads during transport. These specialized formulations provide high tensile strength while maintaining flexibility where needed; this balance is critical when considering the dynamic forces acting on a vehicle during its lifecycle.

Common applications for structural adhesive automotive solutions include joining body panels, attaching glass components like windshields securely into frames, and reinforcing load-bearing areas within a car’s chassis. Furthermore, advancements in curing technologies have allowed these adhesives to set faster than ever before while still delivering outstanding results—an essential factor when striving for efficient production timelines in manufacturing plants.

In summary, embracing various types of automotive adhesives not only enhances product quality but also offers manufacturers a competitive edge through improved design possibilities and operational efficiencies.

Leading Adhesive Manufacturers

In the competitive world of adhesive manufacturing, several key players have established themselves as leaders, particularly in the automotive sector. These companies not only produce high-quality products but also innovate continuously to meet the evolving needs of the automotive adhesives market. Let's take a closer look at three of these influential manufacturers: Henkel, 3M, and Sika.

Henkel: A Pioneer in Adhesives

Henkel has long been recognized as a pioneer in adhesives, with a strong focus on providing innovative solutions for various industries, including automotive adhesives. Their extensive range of products includes everything from general-purpose adhesives to specialized structural adhesive automotive formulations that enhance vehicle performance and durability. With a commitment to research and development, Henkel consistently introduces advanced adhesive technologies that cater specifically to the demands of modern automotive applications.

The company’s dedication to quality is evident in its wide array of adhesives used in the automotive industry, which are designed for bonding materials like metals, plastics, and composites. Henkel's structural adhesive bonding solutions are particularly noteworthy; they ensure robust connections that withstand harsh environmental conditions while maintaining vehicle integrity. As a leader in sustainable practices, Henkel also focuses on creating eco-friendly options that align with global trends toward sustainability.

3M: Innovation and Performance

When it comes to innovation and performance in the realm of automotive adhesives, 3M stands out as a formidable contender. This company is known for its cutting-edge technology that enables high-performance bonding solutions tailored for diverse applications within the automotive sector. From their versatile tape systems to advanced structural adhesive products, 3M continues to push boundaries by developing solutions that enhance vehicle assembly efficiency and overall performance.

The range of adhesives used in the automotive industry by 3M includes everything from instant bonding agents to durable structural adhesive automotive options designed for critical applications like body shop repairs and assembly lines. Their commitment to innovation means they are always at the forefront of new developments—ensuring their customers benefit from state-of-the-art products that deliver reliability under pressure. As vehicles become more complex with lightweight materials and intricate designs, 3M's contributions significantly impact how manufacturers approach adhesion challenges.

Sika: Specializing in Structural Adhesives

Sika has carved out a niche specializing in structural adhesives tailored specifically for use within the automotive industry. With an emphasis on performance-driven solutions, Sika's portfolio includes various formulations designed for optimal strength and flexibility—making them ideal for structural adhesive bonding applications where traditional methods may fall short. Their innovative approach ensures vehicles can achieve higher safety ratings while benefiting from reduced weight through effective use of advanced materials.

The company's expertise extends beyond just manufacturing; Sika actively collaborates with automakers to develop customized solutions that meet unique production requirements or specifications related to their vehicles' design or function. By focusing on delivering high-quality structural adhesive automotive options that enhance both bond strength and durability under extreme conditions, Sika remains an essential partner for many leading car manufacturers worldwide. Their commitment to sustainability also aligns with modern industry standards aimed at reducing environmental impacts while maintaining superior product performance.

Water-Based Resin Solutions

In the ever-evolving landscape of automotive adhesives, water-based resin solutions are carving out a niche that is hard to ignore. These innovative adhesives are not only environmentally friendly but also offer exceptional performance in various applications within the automotive industry. As manufacturers strive for sustainable practices, water-based resins are becoming increasingly popular in adhesive automotive formulations.

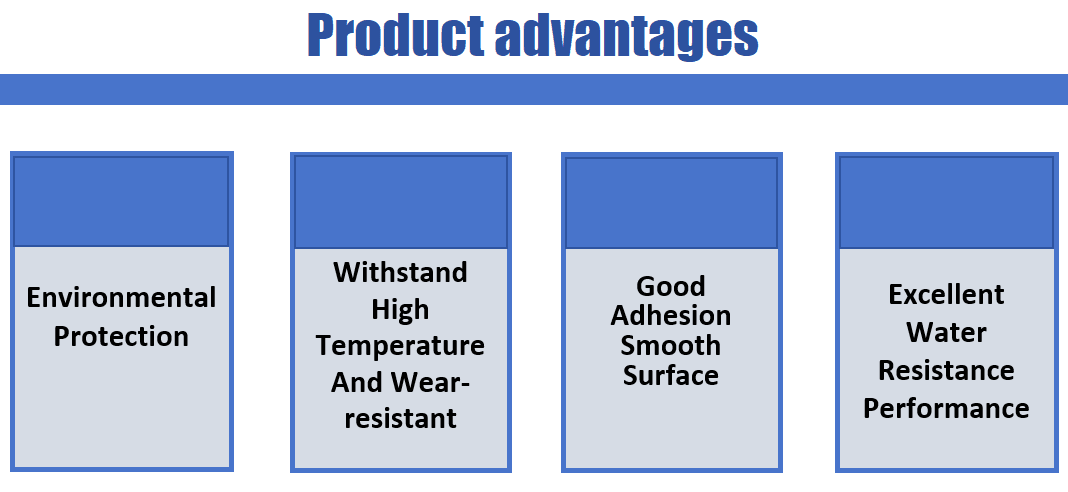

Chemix's Water-Based Resin Overview

Chemix has emerged as a key player in the development of water-based resin solutions tailored for automotive adhesives. Their products are designed to meet the unique demands of structural adhesive bonding, providing strong adhesion while minimizing environmental impact. By focusing on low VOC (volatile organic compounds) formulations, Chemix ensures that their water-based resins contribute to cleaner air quality and safer working conditions in automotive manufacturing.

Benefits of Water-Based Resins

The benefits of using water-based resins in the automotive sector are manifold and compelling. First and foremost, these adhesives used in the automotive industry offer excellent adhesion properties without compromising on flexibility or durability—essential qualities for any structural adhesive automotive application. Additionally, they facilitate easier cleanup and handling compared to solvent-based options, making them a favorite among manufacturers looking for efficiency and safety.

Moreover, water-based resins often exhibit superior resistance to temperature fluctuations and moisture exposure, which is critical for vehicles subjected to varying environmental conditions. This resilience ensures that structural adhesive bonding remains intact over time, enhancing vehicle longevity and reliability.

Applications in Automotive Adhesive Solutions

Water-based resin solutions find diverse applications across various segments of the automotive industry. They are particularly effective in bonding components such as interior trim pieces, glass installations, and even underbody coatings where flexibility is essential. The versatility of these adhesives means they can be utilized effectively with different substrates commonly found in vehicles today.

Furthermore, as OEMs (Original Equipment Manufacturers) continue to innovate with lightweight materials like composites and advanced plastics, water-based resins provide an ideal solution for creating strong bonds without adding significant weight—crucial for improving fuel efficiency and overall vehicle performance. In this way, water-based resins not only enhance adhesive performance but also align with broader trends toward sustainability within the sector.

Trends in the Adhesive Industry

The adhesive industry is undergoing a significant transformation, particularly in the automotive sector. Innovations are paving the way for more efficient, durable, and environmentally friendly solutions. As automotive adhesives evolve, they not only enhance vehicle performance but also contribute to sustainability efforts.

Advances in Adhesive Technology

Recent advances in adhesive technology have revolutionized how we approach bonding materials in vehicles. From high-performance epoxy formulations to innovative structural adhesive bonding techniques, automotive adhesives are becoming stronger and more versatile. These developments allow manufacturers to create lighter vehicles with improved fuel efficiency while maintaining safety standards.

Moreover, smart adhesives that respond to environmental changes are gaining traction in the automotive industry. These adhesives can adapt their properties based on temperature or stress levels, enhancing their effectiveness over time. As a result, the integration of these advanced technologies is reshaping how adhesives used in the automotive industry perform under various conditions.

Sustainable Practices in Adhesive Manufacturing

Sustainability is no longer just a buzzword; it’s a necessity driving change across all industries, including adhesive manufacturing. Manufacturers are increasingly focusing on eco-friendly materials and processes when producing automotive adhesives. This includes utilizing renewable resources for raw materials and minimizing waste during production.

Water-based formulations are also gaining popularity as sustainable options for structural adhesive automotive applications. These alternatives reduce volatile organic compounds (VOCs) and provide safer working environments without compromising performance. By adopting sustainable practices, companies can contribute to reducing their carbon footprint while meeting consumer demand for greener products.

Future of Automotive Structural Adhesives

Looking ahead, the future of automotive structural adhesives appears promising as new challenges arise with evolving vehicle designs and materials. Lightweight composites and electric vehicle components require specialized bonding solutions that traditional methods may not adequately address. The continued development of high-strength structural adhesive bonding will be crucial for ensuring safety and durability in modern vehicles.

In addition to functionality, future trends will likely focus on enhancing recyclability within adhesive systems used in the automotive sector. Manufacturers will need to innovate ways to ensure that these products can be easily removed or recycled at end-of-life stages without harming other materials involved in vehicle construction. As such innovations unfold, they will shape not only how we bond but also how we think about sustainability within the entire lifecycle of vehicles.

Conclusion

In the rapidly evolving world of automotive adhesives, selecting the right adhesive supplier is crucial for achieving optimal performance and durability in vehicle manufacturing. The right partner not only provides high-quality products but also offers expertise in adhesive technology that can enhance production efficiency. With a plethora of options available, understanding the specific needs of your project is key to making an informed choice in the adhesive automotive market.

Choosing the Right Adhesive Supplier

When it comes to adhesives used in the automotive industry, not all suppliers are created equal. A reliable supplier should offer a comprehensive range of products, including structural adhesive automotive solutions that meet stringent safety and performance standards. Additionally, consider their customer support and technical assistance; having access to expert advice can make all the difference when navigating complex bonding requirements.

The Future of Adhesives in Automotive

The future of adhesives in the automotive sector looks bright as innovations continue to reshape how vehicles are manufactured and assembled. With increasing demands for lightweight materials and enhanced fuel efficiency, automotive structural adhesive applications are becoming more prevalent than ever before. As manufacturers seek sustainable solutions, advancements in eco-friendly adhesives will likely play a pivotal role in shaping this industry's landscape.

Innovations Shaping the Adhesive Market

Innovations are at the forefront of transforming traditional bonding methods into advanced structural adhesive bonding techniques that promise better performance and longevity. From smart adhesives that respond to environmental changes to bio-based formulations that reduce environmental impact, creativity knows no bounds in this field. As we look ahead, these innovations will redefine how we perceive and utilize automotive adhesives across various applications.