Introduction

In the world of automotive interiors, the unsung hero often goes unnoticed—adhesive glue for cars. These industrial adhesives play a pivotal role in ensuring that components are securely bonded, contributing to both safety and aesthetics. As vehicles evolve, so too does the need for advanced adhesive solutions that can meet the demands of modern design and functionality.

The Role of Adhesives in Automotive Interiors

Adhesives are essential in automotive interiors, providing a seamless bond between various materials like plastics, metals, and fabrics. This bonding not only enhances structural integrity but also allows for innovative designs that were once thought impossible with traditional fasteners. Industrial adhesive products have become indispensable in creating comfortable, visually appealing spaces within vehicles while ensuring long-lasting durability.

Why Choose Industrial Adhesives for Vehicle Assembly

When it comes to vehicle assembly, choosing industrial adhesives over conventional methods offers numerous advantages. These adhesives provide superior bond strength and flexibility, allowing manufacturers to create lightweight structures without compromising safety or performance. Furthermore, many industrial adhesive suppliers offer specialized formulations tailored to specific automotive applications, making it easier for manufacturers to select the right product for their needs.

The Environmental Benefits of Adhesive Solutions

The shift towards sustainable practices has made environmental considerations crucial in adhesive manufacturing processes. Water-based adhesives and other eco-friendly options reduce harmful emissions and promote safer working conditions within factories. By opting for these environmentally friendly solutions from leading industrial adhesive manufacturers, automakers can significantly lessen their ecological footprint while delivering high-quality vehicles equipped with reliable adhesive glue for cars.

Understanding Automotive Adhesives

In the automotive industry, choosing the right adhesive glue for cars is crucial for ensuring optimal performance and longevity. Various types of adhesives are used in vehicle assembly, each tailored to meet specific requirements such as bonding strength, flexibility, and environmental resistance. With advancements in adhesive manufacturing techniques, industrial adhesive products have become essential components in modern automotive design.

Types of Adhesive Glue for Cars

When it comes to adhesive glue for cars, several types stand out: epoxy, polyurethane, acrylics, and pressure-sensitive adhesives are among the most commonly used. Epoxy adhesives provide exceptional bond strength and durability, making them ideal for structural applications where safety is paramount. On the other hand, polyurethane adhesives offer flexibility and resistance to moisture, making them suitable for exterior applications exposed to varying weather conditions.

Pressure-sensitive adhesive manufacturers have also made significant strides in developing products that provide strong adhesion without requiring additional curing time or heat application. These adhesives are often used in interior applications where quick assembly is beneficial. Understanding these different types helps automotive manufacturers choose the right industrial adhesive based on their specific needs.

Key Properties of Effective Adhesives

The effectiveness of any industrial adhesive hinges on several key properties: bond strength, curing time, temperature resistance, and chemical stability are among the most critical factors to consider. A strong bond ensures that components remain securely attached under various stress conditions encountered during vehicle operation. Additionally, a fast curing time can significantly enhance production efficiency by allowing quicker assembly processes.

Temperature resistance is vital as vehicles are subjected to extreme conditions; an effective adhesive must maintain its integrity whether it’s sweltering summer heat or frigid winter temperatures. Chemical stability ensures that the bond remains intact even when exposed to automotive fluids like oil or gasoline. By focusing on these properties during selection from industrial adhesive suppliers, manufacturers can ensure long-lasting performance in their vehicles.

The Science Behind Adhesive Manufacturing

Adhesive manufacturing is a complex process that combines chemistry with engineering principles to create high-performance products tailored for various applications including automotive use. This process often involves formulating polymers that can be processed into liquid or solid forms before being applied as an adhesive glue for cars. The choice of raw materials directly impacts the final product's properties such as viscosity and adhesion capabilities.

Moreover, advancements in technology have allowed industrial adhesive manufacturers to develop eco-friendly formulations that reduce environmental impact while maintaining high performance standards—an increasingly important factor in today’s market landscape. The science behind this innovation often focuses on creating water-based resins or solvent-free systems that align with sustainability goals without sacrificing effectiveness or safety standards.

Enhancing Structural Integrity

In the world of automotive design, structural integrity is paramount. This is where adhesive glue for cars comes into play, providing not just a bond but a vital safety feature that enhances the overall robustness of vehicles. The use of industrial adhesives in car assembly ensures that components are securely held together, reducing the risk of failure during operation.

How Adhesives Improve Vehicle Safety

Adhesives play a crucial role in improving vehicle safety by distributing stress across bonded surfaces more evenly than traditional fasteners. This means that in the event of an impact, areas bonded with industrial adhesive products can absorb and dissipate energy better than those held together by screws or rivets. As a result, vehicles become safer for passengers and pedestrians alike, showcasing how innovative adhesive manufacturing contributes to modern automotive safety standards.

Bond Strength and Durability in Car Assembly

When it comes to bond strength and durability, industrial adhesives are designed to withstand extreme conditions—be it temperature fluctuations or exposure to moisture. Unlike traditional fasteners that may loosen over time due to vibrations or wear, adhesive glue for cars maintains its integrity throughout the vehicle's lifespan. This long-lasting performance is why many automotive manufacturers turn to reputable industrial adhesive suppliers when seeking reliable solutions for their assembly needs.

Comparing Adhesives to Traditional Fasteners

While traditional fasteners like bolts and screws have served their purpose well over the years, they come with limitations that adhesives can overcome effectively. For instance, industrial adhesives provide a seamless finish without protruding parts that can create drag or aesthetic issues in modern vehicle designs. Moreover, pressure-sensitive adhesive manufacturers have developed products that offer quick bonding capabilities without compromising on strength—making them an attractive alternative for automotive engineers looking to innovate.

Boosting Design Flexibility

In the ever-evolving automotive industry, design flexibility is paramount, and industrial adhesives play a pivotal role in achieving this goal. The versatility of adhesive glue for cars allows manufacturers to explore innovative designs without compromising structural integrity or safety. By leveraging industrial adhesive products, designers can break free from traditional constraints, creating vehicles that are not only functional but also visually stunning.

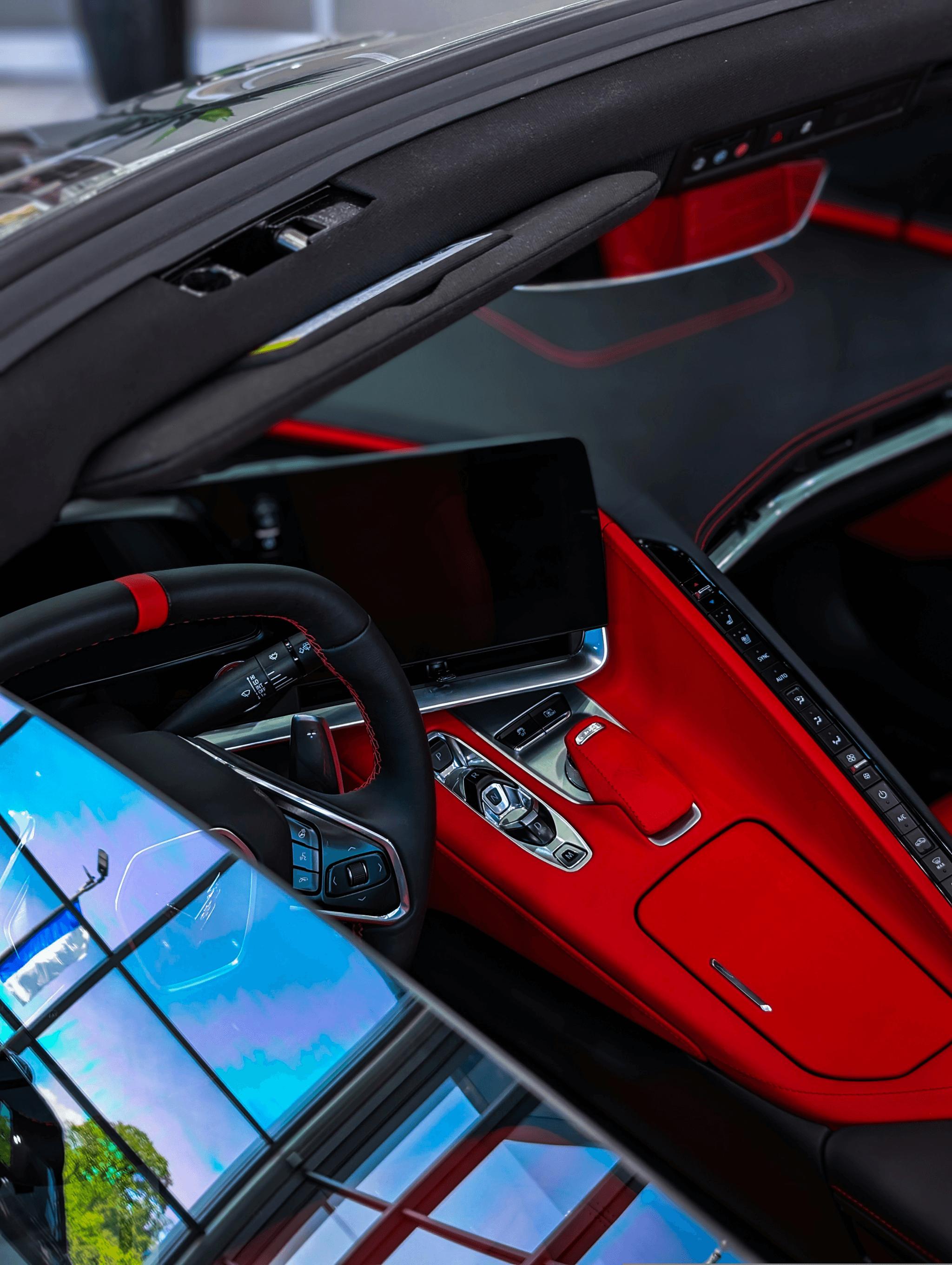

Customization Options with Industrial Adhesive Products

One of the standout features of industrial adhesives is their ability to offer extensive customization options for automotive interiors. Manufacturers can choose from a variety of formulations tailored to specific applications, ensuring that every component fits seamlessly into the overall design. This level of customization allows for unique shapes and configurations that traditional fasteners simply cannot accommodate.

Moreover, industrial adhesive suppliers provide a spectrum of colors and finishes that can enhance the aesthetic appeal of vehicle interiors. This means that car manufacturers can create a cohesive look across various components while maintaining high performance standards with their chosen adhesive glue for cars. As a result, consumers benefit from personalized vehicles that reflect their individual tastes and preferences.

Lightweight Solutions for Modern Interiors

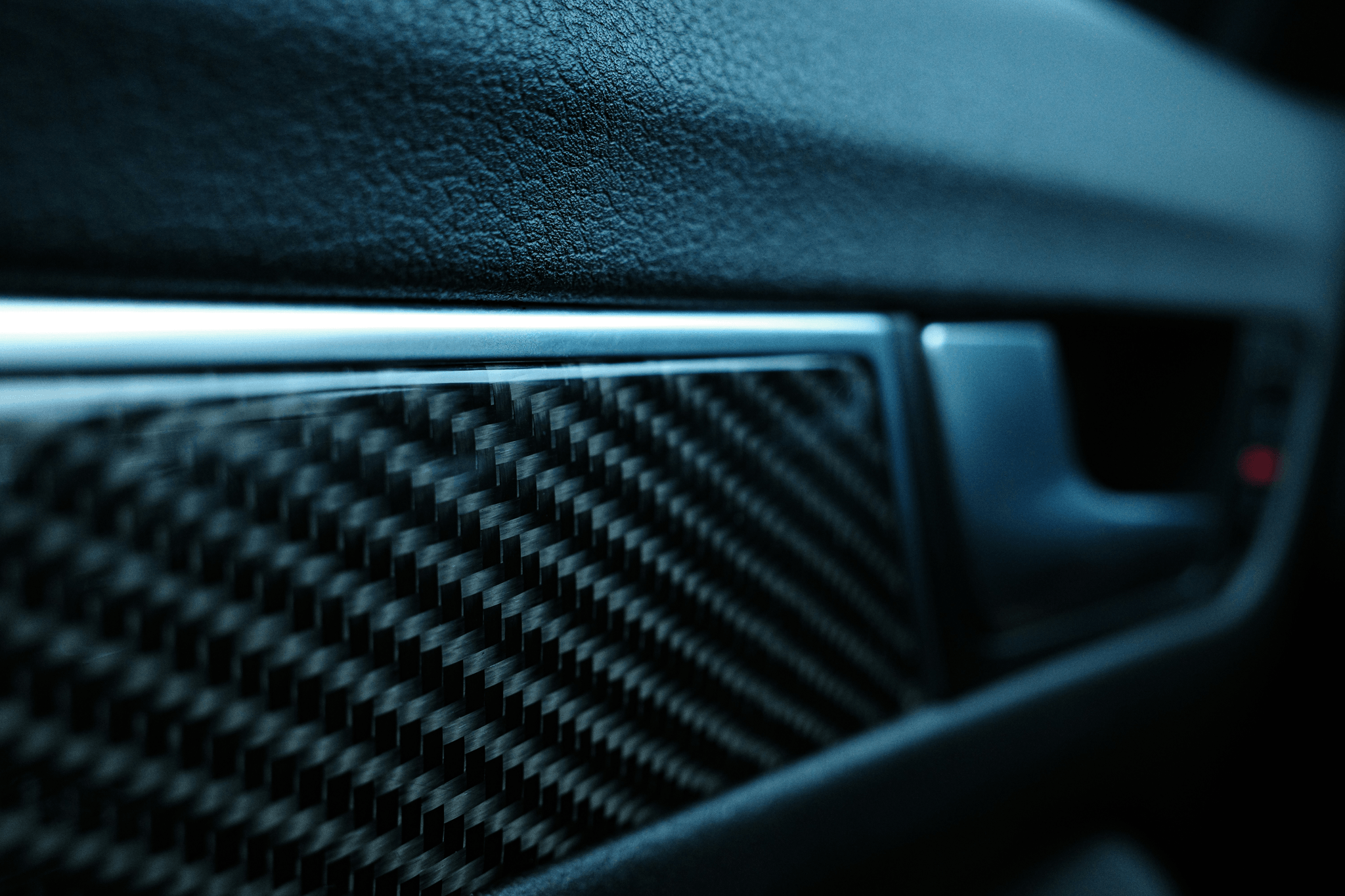

Weight reduction has become a significant focus in automotive design, particularly as manufacturers strive to improve fuel efficiency and reduce emissions. Industrial adhesives present lightweight solutions compared to conventional fastening methods like screws or welds, contributing to overall vehicle weight savings without sacrificing strength or safety. By integrating these adhesives into assembly processes, automakers can achieve better performance metrics while enhancing passenger comfort.

Furthermore, the use of lightweight materials combined with effective adhesive manufacturing techniques enables the creation of modern interiors that are both functional and stylish. For instance, thinner panels bonded with high-performance adhesives maintain structural integrity while offering sleek aesthetics. This synergy between lightweight solutions and industrial adhesive products paves the way for innovative designs in future vehicles.

Enhancing Aesthetic Appeal with Adhesive Technologies

The aesthetic potential unlocked by adhesive technologies cannot be overstated; they allow designers to craft visually striking interiors without the unsightly bulk associated with traditional fastening methods. With pressure sensitive adhesive manufacturers leading the charge in developing advanced bonding solutions, automotive interiors can feature smooth lines and seamless transitions between materials—think leather against metal or plastic against glass—without visible joints or fasteners interrupting the flow.

Additionally, modern adhesives enable intricate designs such as curved surfaces or layered textures that elevate an interior's elegance and sophistication. These enhancements not only appeal to consumers but also set brands apart in a competitive market where style often dictates choice. As such, using high-quality industrial adhesive products becomes essential for any manufacturer looking to stay ahead in both form and function within their vehicle offerings.

Chemix's Water-Based Resin Solution

In the evolving landscape of automotive manufacturing, Chemix's water-based resin solution stands out as a beacon of sustainability and innovation. This industrial adhesive product not only meets the rigorous demands of vehicle assembly but also aligns with growing environmental consciousness. By incorporating such advanced adhesive glue for cars, manufacturers can enhance performance while reducing their ecological footprint.

Sustainable Advantages of Water-Based Resins

Water-based resins offer significant sustainable advantages over traditional solvent-based adhesives, primarily due to their lower volatile organic compound (VOC) emissions. This means that when using these industrial adhesive products, manufacturers contribute to cleaner air quality both in production facilities and in the environment at large. Additionally, many industrial adhesive suppliers are now focusing on developing formulations that utilize renewable resources, making these adhesives a more environmentally friendly option in automotive applications.

The shift towards water-based solutions reflects a broader trend among pressure-sensitive adhesive manufacturers who prioritize sustainability without sacrificing performance. By choosing water-based resins from reputable industrial adhesive manufacturers like Chemix, companies can ensure that they are making responsible choices that resonate with eco-conscious consumers. Ultimately, this commitment to sustainability is not just good for the planet; it also enhances brand reputation and consumer loyalty.

Performance Versatility in Automotive Applications

When it comes to performance versatility, Chemix's water-based resin solution shines brightly in various automotive applications. These adhesives exhibit exceptional bonding capabilities across different substrates commonly found in vehicle interiors and exteriors, including plastics, metals, and composites. The adaptability of these industrial adhesives allows manufacturers to streamline their processes while maintaining high standards of quality and durability.

Moreover, the use of water-based resins does not compromise on strength or durability; rather, they often exceed expectations when tested under extreme conditions typical of automotive environments. Their ability to withstand temperature fluctuations and moisture makes them ideal for both interior fittings and exterior components where resilience is crucial. As such, these innovative solutions from leading industrial adhesive suppliers are paving the way for more efficient vehicle assembly processes.

Safe and Non-Toxic Properties for Consumer Safety

One of the standout features of Chemix's water-based resin solution is its safe and non-toxic properties—an essential consideration for any manufacturer concerned about consumer safety. Unlike many traditional adhesives that may release harmful chemicals during application or throughout a product’s lifecycle, these industrial adhesive products provide peace of mind by being free from hazardous substances. This commitment to safety is particularly important as consumers become increasingly vigilant about health implications associated with automotive materials.

Additionally, by utilizing non-toxic adhesives in vehicle assembly—such as those offered by pressure-sensitive adhesive manufacturers—companies can further enhance their marketability by promoting safer vehicles for families and individuals alike. Choosing safe materials not only fosters consumer trust but also aligns with regulatory requirements aimed at reducing toxic exposure in everyday products. In this way, Chemix's innovative solutions exemplify how modern technology can meet both performance needs and health standards within the automotive industry.

Leading Industrial Adhesive Manufacturers

In the evolving landscape of automotive manufacturing, industrial adhesive manufacturers play a pivotal role in shaping vehicle assembly processes and enhancing product performance. These companies produce a variety of adhesive glue for cars, enabling manufacturers to achieve superior bonding solutions that meet stringent safety and durability standards. As the demand for innovative materials grows, so does the influence of leading industrial adhesive suppliers who are constantly pushing the envelope in adhesive manufacturing.

Top Players in the Adhesive Industry

The adhesive industry boasts several prominent players known for their expertise in producing high-quality industrial adhesive products. Companies like 3M, Henkel, and H.B. Fuller have established themselves as leaders by offering a diverse range of adhesives tailored specifically for automotive applications. Their commitment to research and development ensures that they remain at the forefront of innovation, continually providing cutting-edge solutions that cater to the unique needs of vehicle manufacturers.

These top-tier industrial adhesive manufacturers not only supply traditional adhesives but also specialize in advanced formulations such as pressure-sensitive adhesives that enhance assembly efficiency and reduce production costs. By integrating these technologies into their offerings, they enable automotive companies to streamline operations while maintaining high-performance standards. As competition intensifies within this sector, continuous improvement and adaptation will be key themes among these industry giants.

Industry Innovations from Adhesive Suppliers

Innovation is a cornerstone of success within the industrial adhesive market, with suppliers consistently introducing new technologies designed to improve performance and sustainability. Recent advancements include smart adhesives that respond to environmental changes or stress conditions, thereby enhancing safety features in vehicles equipped with these modern materials. Furthermore, many industrial adhesive suppliers are focusing on developing eco-friendly formulations that align with global sustainability goals.

For instance, some manufacturers are pioneering bio-based adhesives derived from renewable resources which offer comparable performance to traditional synthetic options without compromising safety or effectiveness. This shift towards sustainable practices is not just beneficial for the environment but also appeals to consumers who increasingly prioritize green solutions when purchasing vehicles. The integration of technology into industrial adhesive products continues to evolve rapidly, paving the way for smarter and more efficient bonding solutions.

Future Trends in Adhesive Technologies

Looking ahead, several trends are poised to shape the future of adhesive technologies within the automotive sector. One major trend is the growing emphasis on lightweight materials; as automakers strive for improved fuel efficiency and reduced emissions, using lightweight industrial adhesives becomes essential for achieving these goals without sacrificing structural integrity or performance quality.

Additionally, advancements in automation will likely influence how adhesives are applied during manufacturing processes; automated dispensing systems can enhance precision while minimizing waste associated with traditional application methods. Furthermore, ongoing research into nanotechnology could lead to even more robust adhesion properties by enhancing molecular interactions between surfaces bonded by various types of adhesive glue for cars.

As we navigate through this exciting evolution in bonding technology driven by leading industrial adhesive manufacturers and innovative suppliers alike, it’s clear that both vehicle design flexibility and environmental considerations will continue shaping future developments in this field.

Conclusion

In the ever-evolving world of automotive manufacturing, the role of adhesives cannot be overstated. From enhancing structural integrity to boosting design flexibility, adhesive glue for cars is at the forefront of modern vehicle assembly. By integrating industrial adhesive products into their processes, manufacturers can optimize performance and ensure longevity in their vehicles.

Maximizing Performance with Adhesives

To truly maximize performance in automotive applications, understanding the nuances of adhesive manufacturing is essential. Different types of industrial adhesives offer unique benefits that can cater to specific needs—from bonding lightweight materials to ensuring robust durability under stress. When properly selected and applied, these adhesives not only enhance safety but also contribute significantly to overall vehicle efficiency.

Choosing the Right Adhesive for Your Needs

Selecting the right adhesive glue for cars involves considering various factors such as bond strength, flexibility, and environmental impact. Engaging with reputable industrial adhesive manufacturers can provide insights into which products are best suited for your specific application requirements. Moreover, exploring options from leading industrial adhesive suppliers allows you to assess innovations that could elevate your assembly process while adhering to safety standards.

The Future of Automotive Adhesives in Green Solutions

Looking ahead, the future of automotive adhesives is undoubtedly leaning towards greener solutions that prioritize sustainability without compromising performance. With advancements in water-based and eco-friendly formulations from pressure sensitive adhesive manufacturers, we are witnessing a shift toward more responsible manufacturing practices in the industry. Embracing these innovations will not only meet consumer demands for safer vehicles but also contribute positively to our planet's health.