Introduction

In the ever-evolving landscape of manufacturing and product assembly, the hot melt adhesives market has emerged as a cornerstone for various industries. These versatile bonding solutions are not only efficient but also adaptable to numerous applications, making them essential in sectors ranging from automotive to consumer goods. As we dive into the significance of Chemix within this dynamic market, it becomes clear that their innovative approaches are shaping the future of adhesive technology in Asia.

Understanding the Hot Melt Adhesives Market

The hot melt adhesive glue sector is characterized by its rapid growth and diverse applications, underpinned by a constant demand for reliable bonding solutions. The unique properties of hot melt adhesives—such as quick setting times and strong adhesion—make them ideal for a wide range of products, from packaging to furniture assembly. As manufacturers seek to enhance production efficiency while maintaining quality, hot melt adhesives have become indispensable tools in their arsenal.

Significance of Chemix in Asia

Chemix stands out as a key player in the Asian hot melt adhesive landscape, known for its commitment to innovation and quality. By focusing on advanced formulations like Hot Melt Adhesive Film, Chemix meets the specific needs of local industries while adhering to international standards. Their strategic positioning allows them to cater effectively to markets such as mattress assembly and hygiene products, solidifying their reputation as a trusted supplier across Asia.

Diverse Applications of Chemix Products

The versatility of Chemix's product offerings is evident across various sectors where hot melt adhesive glue plays a crucial role. From enhancing mattress assembly processes with specialized films to ensuring reliability in cigarette filter rod side seaming, Chemix provides tailored solutions that address unique industry challenges. Additionally, their innovations extend into hygiene products, where safety and efficacy are paramount, showcasing just how far-reaching the impact of their adhesives truly is.

What is Hot Melt Adhesive Glue?

Hot melt adhesive glue is a thermoplastic adhesive that is applied in a molten state and solidifies upon cooling. This unique characteristic allows for quick bonding, making it an ideal choice for various applications across multiple industries. From Mattress Assembly to Cigarette Filter Rod Side Seaming, hot melt adhesives are versatile solutions that enhance efficiency and performance.

Definition and Functionality

Hot melt adhesive glue is defined by its ability to transition from solid to liquid when heated, allowing it to bond materials effectively as it cools and hardens. This functionality makes it particularly useful in high-speed manufacturing processes where quick assembly is crucial. Whether used in the production of hygiene products or in the intricate assembly of Hot Melt Adhesive Film, these glues provide reliable adhesion that meets rigorous industry standards.

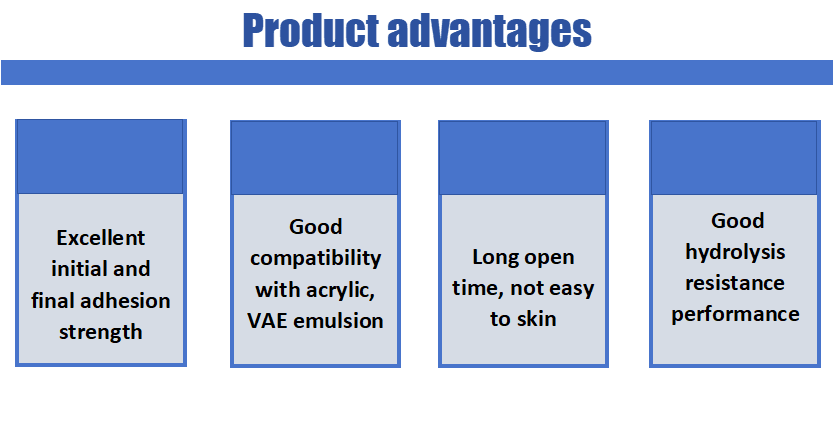

Advantages of Using Hot Melt Adhesives

One significant advantage of hot melt adhesives is their rapid curing time; they bond quickly, reducing production delays and increasing overall efficiency. Additionally, these adhesives offer excellent flexibility and durability, making them suitable for various substrates including plastics, wood, and textiles. Moreover, with innovations like Chemix’s water-based resin solutions on the rise, users can also enjoy eco-friendly options without compromising on performance.

Key Industries Utilizing Hot Melt Adhesives

The applications of hot melt adhesive glue span across numerous industries due to their adaptability and effectiveness. The furniture industry heavily relies on hot melt adhesives for Mattress Assembly to ensure strong seams that withstand everyday use. Similarly, the cigarette manufacturing sector utilizes these adhesives for Cigarette Filter Rod Side Seaming to maintain product integrity while enhancing production speed—showcasing just how vital hot melt adhesives are in modern manufacturing processes.

Chemix: Innovating Hot Melt Adhesive Film

In the world of adhesives, Chemix stands out by pushing the boundaries of Hot Melt Adhesive Film technology. This innovative product offers a unique blend of performance and versatility, making it an essential component across various industries. With applications ranging from Mattress Assembly to Cigarette Filter Rod Side Seaming and Hygiene Products, Chemix is redefining how we think about adhesive solutions.

Introduction to Hot Melt Adhesive Film

Hot Melt Adhesive Film is a game changer in the adhesive landscape, providing a solid alternative to traditional liquid adhesives. Unlike its counterparts, this film format allows for cleaner application and less mess, which is a significant advantage in high-speed production environments. The ability to bond quickly and effectively without waiting for curing time makes Hot Melt Adhesive Glue an attractive choice for manufacturers looking to optimize efficiency.

Hot Melt Adhesive Film is particularly effective due to its thermoplastic properties; when heated, it melts into a liquid form that can easily adhere to various substrates. Once cooled, it solidifies into a strong bond that withstands stress and strain over time. This reliability has made it increasingly popular in sectors where durability is paramount.

Applications in Mattress Assembly

When it comes to Mattress Assembly, the role of Hot Melt Adhesive Film cannot be overstated. Manufacturers utilize this adhesive solution for bonding layers of foam and fabric seamlessly, ensuring that every mattress produced meets high-quality standards without compromising on comfort or durability. The quick application process afforded by hot melt technology significantly reduces production time while enhancing overall product quality.

Moreover, using hot melt adhesive glue in mattress assembly allows for precise control during the manufacturing process. This precision helps maintain consistent quality across batches while minimizing waste—a win-win situation for both manufacturers and consumers alike! As demand for innovative sleep solutions grows, so does the reliance on effective adhesive technologies like those offered by Chemix.

In addition to improving assembly efficiency, Hot Melt Adhesive Film also contributes to sustainability efforts within the mattress industry by reducing excess material usage and waste disposal concerns—an important consideration as consumers become more environmentally conscious.

Future Trends in Adhesive Film Technology

Looking ahead, trends indicate that the future of Hot Melt Adhesive Film technology will be shaped by advancements in both formulation and application methods. Manufacturers are increasingly focusing on developing eco-friendly options without sacrificing performance—think water-based resins that are kinder to our planet yet still deliver robust adhesion capabilities across industries like Hygiene Products or even Cigarette Filter Rod Side Seaming.

Furthermore, ongoing research into smart adhesives could revolutionize how we approach bonding applications altogether; imagine films that can change properties based on environmental conditions! Such innovations would not only enhance functionality but also pave the way for entirely new applications within existing markets.

As Chemix continues its commitment to innovation in hot melt adhesive solutions—whether through enhancing existing products or exploring new territories—the potential impact on industry standards is significant. With every advancement made with Hot Melt Adhesive Glue technology comes an opportunity for businesses everywhere to improve their processes while delivering superior products tailored to consumer needs.

Specialty Applications: Cigarette Filter Rod Side Seaming

In the world of cigarette production, the need for reliable and efficient adhesive solutions is paramount. The industry demands adhesives that can withstand various manufacturing processes while ensuring product quality and compliance with regulations. Hot melt adhesive glue has emerged as a favored choice due to its quick bonding capabilities and versatility, particularly in cigarette filter rod side seaming.

Overview of the Cigarette Industry's Adhesive Needs

The cigarette industry operates under stringent standards, necessitating adhesives that are not only effective but also safe for consumers. As production speeds increase, so does the demand for hot melt adhesive glue that can bond quickly without compromising quality. Additionally, manufacturers seek solutions that minimize waste and reduce downtime during production, making hot melt adhesives an essential component in modern cigarette manufacturing.

Role of Hot Melt Adhesives in Cigarette Production

Hot melt adhesive glue plays a crucial role in various stages of cigarette production, especially in filter rod side seaming where precision is key. These adhesives provide strong bonds between filter materials and rod components while ensuring a seamless finish that enhances the overall product appearance. With advancements like Hot Melt Adhesive Film, manufacturers can achieve even greater efficiency and consistency during assembly processes.

Quality and Efficiency Advantages

Utilizing hot melt adhesive glue in cigarette filter rod side seaming offers significant advantages regarding both quality and efficiency. The rapid curing time allows for faster production rates without sacrificing bond integrity, which is vital for maintaining product standards. Furthermore, these adhesives contribute to reduced material costs by minimizing excess usage while providing robust adhesion—proving their worth not just in functionality but also in economic benefits.

Hygiene Products and Adhesive Solutions

In the world of hygiene product manufacturing, adhesives play a crucial role in ensuring that products are safe, effective, and reliable. Hot melt adhesive glue is particularly favored for its strong bonding capabilities and quick setting times, making it ideal for various applications in this sector. From diapers to feminine hygiene products, the right adhesive solution can significantly enhance product performance and user satisfaction.

Importance of Adhesives in Hygiene Product Manufacturing

Adhesives are fundamental to the integrity of hygiene products, providing essential bonds that keep components securely attached throughout their lifecycle. In manufacturing processes like Mattress Assembly or Cigarette Filter Rod Side Seaming, hot melt adhesive glue ensures that materials adhere properly without compromising safety or comfort. The ability to withstand moisture and maintain flexibility makes hot melt adhesives indispensable in creating reliable hygiene solutions.

Chemix's Role in Product Safety and Efficacy

Chemix is at the forefront of innovation when it comes to enhancing product safety and efficacy through advanced adhesive solutions. Their hot melt adhesive film not only provides exceptional bonding strength but also meets strict regulatory standards for safety in hygiene applications. By prioritizing high-quality materials and rigorous testing, Chemix ensures that their adhesives contribute positively to the overall effectiveness of hygiene products.

Innovations in Hygiene Product Adhesives

The landscape of hygiene product adhesives is evolving rapidly, with Chemix leading the charge through innovative approaches. Recent advancements include the development of specialized hot melt adhesive glues designed specifically for sensitive skin applications or those requiring enhanced moisture resistance. As consumer expectations rise for both performance and sustainability, Chemix continues to push boundaries by introducing eco-friendly formulations that align with modern environmental standards while maintaining superior adhesion properties.

The Eco-Friendly Shift: Chemix's Water-Based Resin Solution

In a world increasingly focused on sustainability, Chemix is leading the charge with its innovative water-based resin solutions. These resins offer a greener alternative to traditional hot melt adhesive glue, significantly reducing environmental impact without sacrificing performance. By leveraging advanced technology, Chemix provides products that meet the demands of various industries while promoting eco-friendly practices.

Benefits of Water-Based Resins

Water-based resins come with a host of benefits that make them highly appealing in today’s market. For starters, they emit fewer volatile organic compounds (VOCs), which improves air quality and worker safety during production processes like Mattress Assembly and Cigarette Filter Rod Side Seaming. Moreover, these resins are easier to clean up and handle compared to solvent-based adhesives, making them user-friendly for manufacturers and end-users alike.

Additionally, water-based resins exhibit excellent adhesion properties similar to those found in traditional hot melt adhesive glue but with enhanced flexibility and durability. This makes them suitable for diverse applications across industries such as hygiene products and packaging. Their versatility ensures that businesses can rely on these eco-friendly options without compromising on quality or efficiency.

Applications Across Various Industries

Chemix’s water-based resin solutions have found their way into numerous sectors due to their adaptability and effectiveness. In the hygiene products industry, for example, they play a crucial role in ensuring secure bonding while maintaining product integrity and safety standards. This is particularly important when developing items such as diapers or feminine hygiene products where both performance and comfort are paramount.

Moreover, these eco-friendly adhesives are also gaining traction in applications like Mattress Assembly where strong yet flexible bonds are essential for product longevity and consumer satisfaction. Even in specialized areas such as Cigarette Filter Rod Side Seaming, Chemix’s water-based solutions provide reliable performance while keeping environmental concerns at the forefront of production strategies. The wide-ranging applicability underscores the potential for growth in adopting water-based technologies across various markets.

Commitment to Sustainability and Environmental Responsibility

Chemix's commitment to sustainability goes beyond just offering water-based resins; it's embedded within their entire operational philosophy. By prioritizing environmentally responsible practices throughout their supply chain—from sourcing raw materials to manufacturing processes—they aim to minimize waste and energy consumption effectively. This dedication not only sets them apart from competitors but also aligns with global trends toward greener manufacturing practices.

Furthermore, Chemix actively engages with clients to promote sustainable adhesive solutions tailored specifically for their needs while adhering to strict environmental guidelines. As industries shift towards more sustainable practices, companies that embrace innovations like Chemix's water-based resin solutions will undoubtedly lead the way in setting new standards for eco-consciousness within the marketplace. With this forward-thinking approach, Chemix is not just meeting current demands but paving the path toward a more sustainable future.

Conclusion

In wrapping up our exploration of the hot melt adhesives market, it’s clear that this sector is on a trajectory of growth and innovation, particularly in Asia. As industries continue to evolve, the demand for versatile solutions like hot melt adhesive glue will only increase. Chemix stands at the forefront of this movement, leading the charge with cutting-edge products that cater to diverse applications.

The Future of Hot Melt Adhesives in Asia

The future of hot melt adhesives in Asia looks promising as manufacturers seek efficient and reliable bonding solutions. With industries such as mattress assembly and hygiene products increasingly relying on these adhesives, we can expect advancements that enhance performance and sustainability. Moreover, as consumer preferences shift towards eco-friendly options, innovations in hot melt adhesive glue will likely incorporate greener materials and processes.

Chemix's Impact on Industry Standards

Chemix has made significant strides in setting industry standards through its innovative hot melt adhesive film products. By focusing on quality and efficiency in areas like cigarette filter rod side seaming, Chemix not only meets but often exceeds market expectations. Their commitment to excellence ensures that companies can trust their adhesive solutions to deliver consistent results across various applications.

Choosing the Right Adhesive Solutions for Your Needs

Selecting the right adhesive solution is crucial for any manufacturing process, whether it's for hygiene products or mattress assembly. Understanding the specific requirements of your application will guide you towards the most suitable hot melt adhesive glue options available today. With Chemix's diverse range of products tailored for various industries, finding a perfect fit has never been easier.