Introduction

In the world of automotive manufacturing and repair, choosing the right adhesive can make all the difference between a reliable bond and a costly failure. Water-based adhesives have emerged as a top choice for many applications, thanks to their unique properties and environmental benefits. Understanding these adhesives is essential for anyone looking to enhance their projects with effective sealants & adhesives that stand the test of time.

Understanding Water-Based Adhesives

Water-based adhesives are formulated using water as a primary solvent, making them an eco-friendly alternative to traditional solvent-based options. These adhesives not only provide strong bonding capabilities but also boast a non-toxic profile that is safer for users and the environment alike. In automotive applications, this means you can use adhesive glue without worrying about harmful fumes or residues—truly a win-win situation.

Benefits of Using Automotive Adhesives

Automotive adhesives are designed to withstand the rigors of vehicle operation, including extreme temperatures and vibrations. One of their standout features is their ability to function as high heat adhesive solutions, ensuring durability in challenging conditions like engine compartments or undercarriages. Additionally, using automotive sealant products can help streamline assembly processes while providing long-lasting bonds that contribute to overall vehicle integrity.

Choosing the Right Adhesive for Your Needs

Selecting the right adhesive automotive solution requires careful consideration of your specific application requirements—whether it's bonding metal parts or sealing gaps against moisture intrusion. Factors such as curing time, flexibility, and environmental resistance should guide your decision-making process when it comes to choosing between various adhesives and sealants available on the market today. Ultimately, understanding your needs will empower you to select an optimal car adhesive that ensures success in your projects.

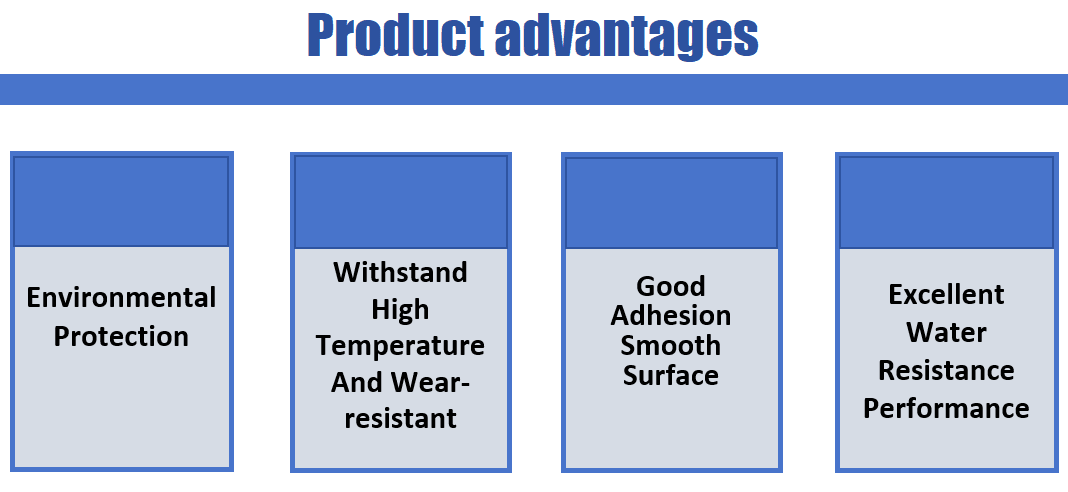

Key Features of Water-Based Adhesives

Water-based adhesives are making waves in the automotive industry, and it's easy to see why. These adhesives and sealants offer a range of key features that cater specifically to the needs of automotive applications. Let's dive into what makes these adhesive solutions stand out from traditional options.

Non-Toxic and Sustainable Options

One of the most appealing aspects of water-based adhesives is their non-toxic nature. Unlike many solvent-based adhesives, these products are free from harmful chemicals, making them a safer choice for both users and the environment. In an age where sustainability is paramount, automotive manufacturers are increasingly opting for eco-friendly adhesive solutions that not only reduce health risks but also lower their carbon footprint.

Choosing non-toxic adhesives means you can use them confidently in various automotive applications without worrying about harmful fumes or residues. This makes them ideal for interior components where air quality matters significantly—think dashboards or upholstery applications. Plus, many water-based options are derived from renewable resources, giving you peace of mind while contributing to a greener planet.

Flexibility and Durability in Automotive Applications

The unique formulation allows these adhesive glues to maintain a strong bond even under challenging conditions such as temperature fluctuations or vibrations experienced during vehicle operation. This flexibility ensures that your adhesive automotive solutions can withstand the rigors of daily driving while maintaining structural integrity.

Moreover, water-based adhesives boast impressive durability against environmental factors like moisture and UV exposure—common culprits that can weaken traditional bonding agents over time. Whether you're working on exterior panels or interior fittings, selecting high-quality automotive sealants ensures long-lasting performance without compromising on aesthetics or function. Ultimately, choosing flexible and durable adhesive options translates into fewer repairs down the line.

High Heat Adhesive Capabilities

In the world of automotive assembly, high heat resistance is crucial for ensuring bonds stay intact under extreme conditions. Water-based high heat adhesive formulations have been engineered to withstand elevated temperatures found in engine compartments or areas near exhaust systems without losing their effectiveness. This capability makes them particularly valuable in modern vehicles where efficient thermal management is essential.

These high heat adhesives not only provide reliable performance but also contribute to overall vehicle safety by ensuring critical components remain securely bonded even when subjected to intense heat cycles during operation. Additionally, using advanced adhesive technologies helps manufacturers meet stringent industry standards while enhancing vehicle longevity through superior adhesion properties. When selecting car adhesive products for high-temperature applications, it's vital to consider those specifically designed with exceptional heat resistance features.

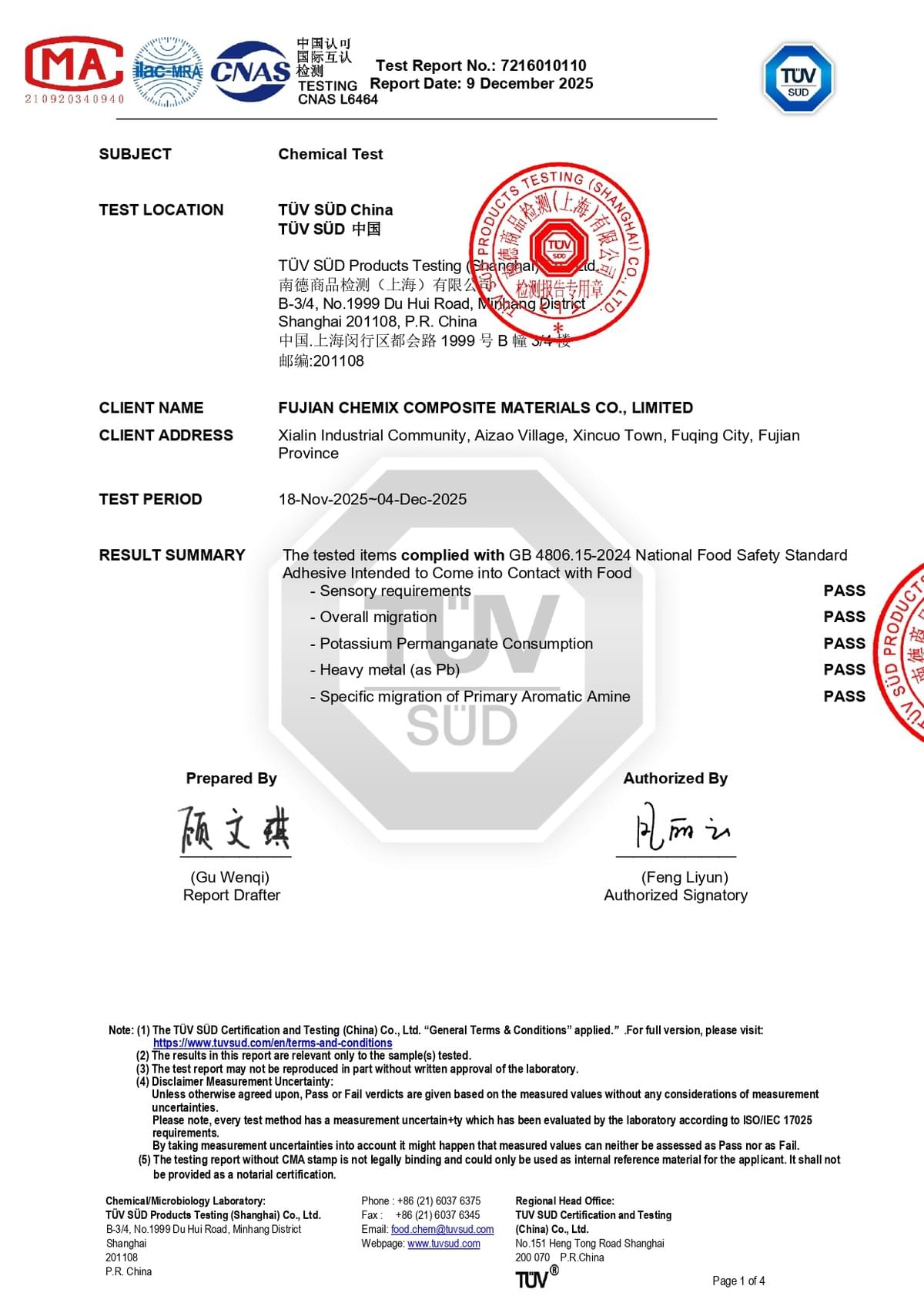

Chemix's Water-Based Resin Solution

This innovative product line is designed specifically for the automotive industry, offering superior performance while prioritizing sustainability and safety. By using Chemix’s adhesive glue, you can ensure that your projects not only meet high standards but also contribute positively to the environment.

Sustainable and Safe for Automotive Use

Chemix's water-based resin is a game-changer in the realm of adhesive automotive solutions, emphasizing sustainability without compromising on quality. Formulated with non-toxic ingredients, these adhesives and sealants are safe for both users and the environment, making them an excellent choice for eco-conscious consumers. As more automotive manufacturers prioritize green practices, using such high-quality car adhesives can significantly enhance your brand’s reputation.

Performance Comparisons with Traditional Adhesives

When evaluating performance, Chemix's water-based solutions hold their own against traditional adhesives and sealants commonly used in the industry. Unlike many solvent-based options that can release harmful fumes or degrade under high heat conditions, Chemix’s high heat adhesive maintains strong bonding capabilities even in extreme environments. This means you won’t have to compromise safety or durability when choosing an automotive adhesive; Chemix delivers both.

Customization for Various Applications

One of the standout features of Chemix's offerings is their ability to customize formulations to suit various applications within the automotive sector. Whether you need a specific viscosity or enhanced adhesion properties for unique materials, this flexibility ensures that every project gets precisely what it needs from its adhesive glue or sealant. With tailored solutions available, you can confidently tackle any challenge while ensuring optimal performance from your chosen automotive sealant.

Tips for Proper Application

When it comes to achieving the best results with your adhesive automotive projects, proper application is crucial. The right techniques can make a world of difference in the strength and durability of your bond. Here are some essential tips to ensure you’re using adhesives and sealants effectively.

Surface Preparation for Best Results

Before applying any adhesive glue, surface preparation is key to ensuring a strong bond. Clean the surfaces thoroughly to remove dirt, grease, and old adhesive residues; this helps the automotive adhesive adhere better. For high heat adhesive applications, roughening smooth surfaces with sandpaper can also enhance adhesion by increasing the surface area for bonding.

In addition to cleaning, consider using a primer designed for automotive sealant applications if recommended by the manufacturer. This step can significantly improve adhesion in challenging environments or on materials like plastics or metals that might be less receptive to adhesives and sealants alone. Remember: a well-prepared surface leads to a more durable bond that withstands time and temperature fluctuations.

Application Techniques for Adhesive Glue

Applying adhesive glue correctly is just as important as preparing the surface; technique matters! Start by following the manufacturer's guidelines regarding application methods—some adhesives work best with brushes or rollers, while others may require a caulking gun or spray application for even distribution. When working with car adhesive products, apply an even layer without overdoing it; too much adhesive can lead to messy results and weakened bonds.

For best results with high heat adhesives specifically designed for automotive use, ensure you apply them in controlled environments when possible—excess humidity or cold temperatures can negatively affect curing times and overall performance. Always allow enough time between layers if you’re using multiple products; patience here pays off in terms of longevity and effectiveness of your bond.

Curing Time and Environmental Considerations

Curing time varies widely among different adhesives and sealants; it's essential to consult product specifications before rushing into further steps! Many automotive adhesives require several hours—or even days—to fully cure depending on environmental conditions like temperature and humidity levels during application. Keep this in mind when planning your project timeline as improper curing can lead to weak bonds that fail under stress.

Additionally, always consider environmental factors when choosing your adhesive automotive solutions; some products perform better under specific conditions than others. For example, high heat adhesives are ideal in areas exposed to extreme temperatures but may not fare well in damp settings without proper sealing techniques involved alongside them. By being mindful of these elements during both application and curing phases, you'll maximize the efficiency of your chosen adhesives and sealants.

Common Mistakes to Avoid

Even the best adhesive automotive products can fail if misapplied or misunderstood. Avoiding common pitfalls can save time, money, and headaches down the road. Here are some key mistakes to steer clear of when using adhesives and sealants in your automotive projects.

Overusing Adhesives and Sealants

One of the most frequent blunders is overusing adhesive glue or sealants, thinking that more means better. In reality, excess adhesive can lead to messy applications and weak bonds, as it may not cure properly under too much pressure. Remember, a thin layer of high heat adhesive is often more effective than a thick glob; less really is more when it comes to automotive adhesives.

Using too much adhesive also complicates clean-up and can cause unsightly overflow that detracts from your vehicle's appearance. Instead of piling on the product, follow manufacturer recommendations for application thickness to ensure optimal performance from your automotive sealant. Trust us; a little restraint will yield impressive results!

Ignoring Environmental Conditions

Another pitfall is ignoring environmental conditions during application. Temperature and humidity levels play critical roles in how well adhesives and sealants bond; applying them in extreme weather can lead to poor adhesion or even complete failure. For instance, high heat adhesive may not perform as intended if applied in frigid temperatures or wet conditions.

It's essential to check the product guidelines for ideal application environments before diving into your project with car adhesive or automotive sealant. Adapting your work schedule based on weather forecasts might seem tedious but will significantly enhance the durability of your bond over time. So don’t let Mother Nature rain on your parade—plan accordingly!

Neglecting Shelf Life of Products

Lastly, neglecting the shelf life of adhesives and sealants is a mistake many make without realizing its consequences until it's too late. Over time, even high-quality automotive adhesives can degrade or lose effectiveness if stored improperly or left past their expiration date. Always check labels for shelf life information and store products according to manufacturer guidelines for optimal performance.

Using expired products could result in weak bonds that jeopardize safety—especially critical when dealing with automotive applications where reliability matters most! Regularly inspect your stockpile of adhesives and sealants to ensure you’re only using fresh materials for repairs or installations on your vehicles. Being mindful of these factors will keep you ahead in maintaining strong adhesion throughout all projects.

Maintenance and Repair Tips

When it comes to ensuring the longevity of your adhesive automotive applications, regular maintenance is key. Just like you wouldn’t skip an oil change, you shouldn’t overlook your adhesive bonds. A little attention can go a long way in preventing costly repairs down the road.

Inspecting Your Adhesive Bond Regularly

Regular inspections of your adhesive bonds can help catch potential issues before they escalate. Look for signs of wear or failure, such as peeling edges or visible gaps in your automotive adhesive applications. Remember, a high heat adhesive might perform well initially but could degrade over time if not monitored properly.

Make it a habit to check these bonds every few months, especially if you live in areas with extreme weather conditions. Environmental factors can affect the integrity of adhesives and sealants; moisture and heat are particularly notorious for causing problems. By being proactive about inspections, you can ensure that your adhesive glue remains effective and reliable.

How to Reapply or Replace Automotive Adhesives

If you discover that an adhesive bond has failed during your inspection, don’t panic! Reapplying or replacing automotive adhesives is usually straightforward if done correctly. First, ensure that any old sealants & adhesives are completely removed from the surface; this will provide a clean slate for new application.

Next, prepare the surface according to manufacturer guidelines—cleaning and drying it thoroughly is essential for optimal adhesion. Once ready, apply your chosen car adhesive using proper techniques to achieve a strong bond; remember that some high heat adhesives may require specific application methods or curing times.

Recommended Sealants and Adhesives for Repairs

Look for automotive sealant options specifically designed for high-stress areas where flexibility is crucial; these will often outperform standard adhesives and sealants in demanding environments.

For general use, consider versatile options like polyurethane-based adhesives that offer excellent bonding capabilities across various materials used in vehicles—from metal to plastic components. Always check compatibility with existing materials before application; this ensures that your chosen adhesive automotive solution will stand up to both time and temperature fluctuations.

Conclusion

In wrapping up our exploration of adhesive automotive solutions, it's clear that the evolution of adhesives and sealants has transformed the industry. As we look toward the future, innovations in high heat adhesive technology and sustainable options will continue to shape how automotive manufacturers approach bonding materials. With a growing emphasis on performance, safety, and environmental responsibility, the next generation of automotive adhesives promises to deliver exceptional results.

The Future of Adhesives in Automotive

The future of adhesives in automotive applications is bright and full of potential. We can expect advancements in adhesive glue formulations that enhance flexibility while maintaining strength under extreme conditions. Furthermore, as electric vehicles become more prevalent, the demand for specialized automotive sealants will rise, leading to even more innovative solutions tailored to meet unique manufacturing challenges.

Environmental Impact of Adhesive Choices

Water-based options not only reduce harmful emissions but also align with global sustainability efforts—making them an excellent choice for eco-conscious consumers. By opting for environmentally friendly car adhesive products, you contribute positively to reducing your carbon footprint while ensuring reliable performance.

Final Tips for Successful Adhesive Use

To maximize the effectiveness of your adhesive automotive products, remember these final tips: always prepare surfaces thoroughly before application; consider environmental conditions like temperature and humidity; and pay attention to product shelf life to avoid mishaps down the line. Proper application techniques can make all the difference when using high heat adhesive or any other type of adhesive glue in your projects. By following these guidelines and selecting quality automotive adhesives wisely, you'll ensure a strong bond that stands the test of time.