Introduction

In a world increasingly focused on sustainability, the exploration of water-based adhesives has gained significant traction. These solvent-free adhesives are not just a passing trend; they represent a pivotal shift towards environmentally friendly glue solutions that cater to various industries, particularly in medical PVC packaging. As we delve into this topic, we will uncover the unique attributes of PVC packaging and how it aligns with the growing demand for eco-conscious materials.

Discovering Water-Based Adhesives

Water-based adhesives have emerged as a game-changer in the adhesive industry, providing robust solutions without compromising safety or performance. Unlike traditional options laden with harmful solvents, these medical PVC packaging glues offer a solvent-free alternative that ensures both strong bonding glue capabilities and user safety. The discovery of these innovative adhesives has opened doors for their application across various sectors, especially in medical disposable device adhesives where reliability is paramount.

The Shift to Eco-Friendly Solutions

As environmental concerns rise globally, industries are pivoting towards eco-friendly solutions that minimize their carbon footprint while maximizing performance. This shift is evident in the increasing adoption of environmentally friendly glue products that prioritize health and safety alongside effectiveness. With water-based options leading the charge, manufacturers can meet regulatory standards while producing high-quality medical PVC packaging that caters to modern sustainability goals.

What Makes PVC Packaging Unique

PVC packaging stands out due to its versatility and durability, making it an ideal choice for various applications, including OTC packaging and medical devices. Its unique properties allow for effective sealing and protection against contamination—critical factors in healthcare settings where hygiene is non-negotiable. Coupled with strong bonding glue provided by water-based adhesives, PVC becomes an invaluable asset in ensuring product integrity throughout its lifecycle.

Advantages of Water-Based Adhesives

Water-based adhesives are revolutionizing the way we think about bonding solutions, especially in the realm of medical PVC packaging. These solvent-free adhesives offer numerous advantages that make them ideal for a variety of applications, particularly in healthcare settings where safety and efficacy are paramount. With their environmentally friendly properties and strong bonding capabilities, they are paving the way for a more sustainable future.

Solvent-Free Performance

One of the standout features of water-based adhesives is their solvent-free performance, setting them apart from traditional options. This means that when using medical PVC packaging glue, you don’t have to worry about harmful solvents evaporating into the air or contaminating your products. The absence of volatile organic compounds (VOCs) makes these adhesives not only safer for users but also better for our planet—an essential consideration in today’s eco-conscious market.

Enhanced Safety for Users

Safety is a top priority in any medical setting, and water-based adhesives deliver on this front with flying colors. Unlike solvent-based alternatives that can release toxic fumes, environmentally friendly glue ensures a healthier working environment for staff handling medical disposable device adhesives. This enhanced safety translates into fewer workplace accidents and health issues, allowing healthcare professionals to focus on what truly matters: patient care.

Superior Bonding Strength

In fact, many manufacturers tout superior bonding strength as one of the key benefits of using these innovative adhesives in OTC packaging and other applications requiring durability and reliability. Whether it’s securing components in medical disposable devices or ensuring seals remain intact during transport, strong bonding glue is essential—and water-based options deliver consistent results every time.

Environmental Benefits of Eco-Friendly Glue

Reducing VOC Emissions

One of the standout features of water-based adhesives is their ability to significantly reduce volatile organic compound (VOC) emissions. Traditional solvent-based adhesives often release harmful VOCs into the atmosphere during application and curing, posing risks to both health and the environment. In contrast, medical PVC packaging glue made from water-based formulations ensures that users benefit from cleaner air quality and less environmental pollution.

By choosing solvent-free adhesives, companies can actively participate in reducing air pollutants that contribute to smog and respiratory issues. This is particularly crucial in settings where medical disposable device adhesives are used, as they often must adhere to strict health standards. Ultimately, lowering VOC emissions not only benefits human health but also aligns with global efforts toward sustainability.

Sustainable Manufacturing Practices

The production process for eco-friendly glue is designed with sustainability at its core. Many manufacturers prioritize sustainable practices by sourcing raw materials responsibly and optimizing energy use during production. For instance, when creating medical disposable device adhesives or OTC packaging solutions, companies can choose renewable resources that minimize waste and reduce carbon footprints.

Additionally, sustainable manufacturing practices extend beyond just material selection; they encompass energy-efficient processes that lower overall resource consumption. This commitment to sustainability resonates well with consumers who are increasingly aware of the environmental impact of their purchases. By embracing these practices, businesses can enhance their brand image while contributing positively to global sustainability goals.

Compliance with Regulatory Standards

In an industry as regulated as healthcare, compliance with stringent standards is non-negotiable—especially for products like medical PVC packaging glue. Water-based adhesive formulations typically meet or exceed regulatory requirements set forth by organizations such as the FDA or EPA due to their inherently safer chemical profiles compared to solvent-based counterparts. This ensures that manufacturers using these environmentally friendly glues can confidently market their products without fear of regulatory backlash.

Moreover, compliance isn't just about meeting current regulations; it's about anticipating future changes in legislation aimed at reducing environmental impacts across industries. As more governments implement stricter guidelines on chemical usage and emissions, businesses utilizing strong bonding glue made from water-based formulations will be well-positioned for continued success in an evolving market landscape. By prioritizing compliance along with sustainability efforts, companies can secure a competitive edge while promoting healthier environments for all.

Comparison: Water-Based vs. Solvent-Based Adhesives

Cost Efficiency Considerations

Cost is always a critical factor in any manufacturing process, and when comparing medical PVC packaging glue options, water-based adhesives often come out on top. These solvent-free adhesives typically require less investment in safety equipment and ventilation systems due to their lower toxicity levels. Additionally, the reduced need for hazardous materials can lead to lower disposal costs over time—making them a financially savvy choice for manufacturers of medical disposable device adhesives.

Performance in Extreme Conditions

Performance is non-negotiable when it comes to medical applications; thus, understanding how each adhesive type performs under pressure is essential. Water-based solutions have shown remarkable resilience even in extreme conditions like high humidity or temperature fluctuations—often outperforming their solvent-based counterparts. This reliability makes them an excellent choice for OTC packaging that might be exposed to various environmental factors throughout its lifecycle.

Long-Term Stability in Medical Applications

Long-term stability is paramount for any adhesive used in healthcare settings; after all, you wouldn’t want your strong bonding glue to weaken over time! Water-based adhesives have been developed with advanced formulations that ensure they maintain their integrity even after prolonged exposure to sterilization processes or other challenging conditions typical of medical environments. This durability makes them ideal candidates not just for medical PVC packaging but also for a wide range of applications where consistent performance is critical.

Applications in Medical PVC Packaging

Medical PVC packaging is revolutionizing the way we think about safety and efficiency in healthcare. One of the standout features of this packaging is its reliance on **medical PVC packaging glue**, which offers a solvent-free solution that aligns with modern eco-friendly initiatives. As healthcare continues to prioritize sustainability, the demand for environmentally friendly glue has surged, making it a vital component in various medical applications.

Ideal for Medical Disposable Devices

When it comes to medical disposable devices, strong bonding glue is essential for ensuring safety and reliability. The use of **medical disposable device adhesives** allows manufacturers to create products that are not only effective but also safe for patients and users alike. These solvent-free adhesives provide a robust bond that can withstand various sterilization processes, making them perfect for applications like syringes, IV bags, and surgical instruments.

Effective Use in OTC Packaging

Over-the-counter (OTC) packaging demands high standards of safety and performance, where **environmentally friendly glue** plays a crucial role. Utilizing water-based adhesives ensures that the packaging maintains integrity while being free from harmful solvents that could leach into products. This approach not only enhances consumer confidence but also supports regulatory compliance, positioning companies as leaders in sustainable practices within the OTC market.

Real-World Success Stories

Several companies have successfully integrated **solvent-free adhesives** into their medical PVC packaging solutions with remarkable results. For instance, one leading manufacturer reported a 30% increase in production efficiency after switching to water-based adhesives for their medical devices—showcasing how strong bonding glue can enhance both performance and environmental responsibility. These real-world success stories highlight the transformative potential of using innovative adhesives in medical applications while reinforcing the importance of choosing eco-friendly options.

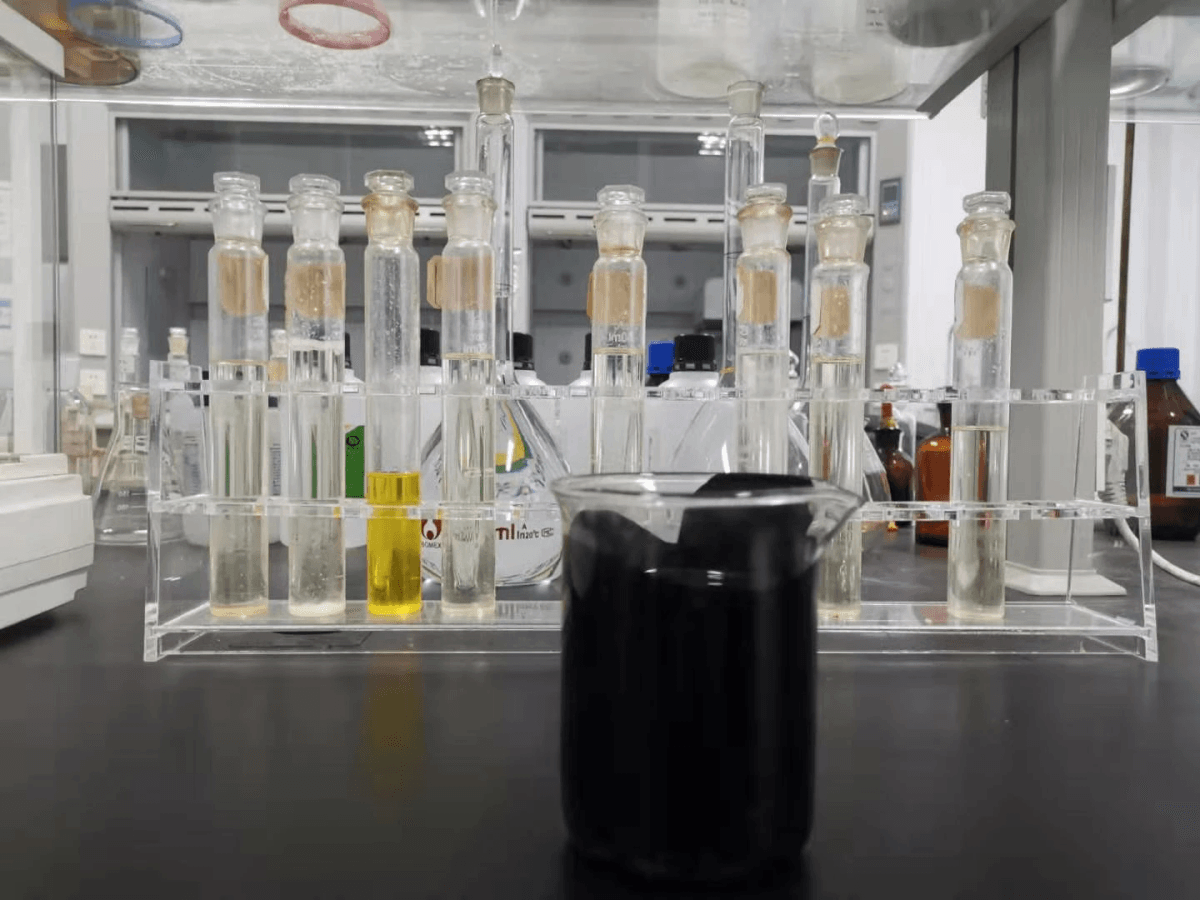

Chemix's Water-Based VC Composite Adhesive

Chemix has taken the world of medical PVC packaging by storm with its innovative water-based VC composite adhesive. This solvent-free adhesive excels in creating strong bonds while maintaining a commitment to environmental sustainability. Designed specifically for medical applications, it meets the rigorous demands of both medical disposable device adhesives and OTC packaging.

Innovative Features of Chemix Adhesive

What sets Chemix's water-based adhesive apart is its unique formulation that enhances bonding strength without compromising safety. Unlike traditional adhesives, this product is solvent-free, making it a healthier choice for users and the environment alike. Its versatility allows it to be used effectively across various applications, from medical PVC packaging to everyday OTC packaging solutions.

Energy-Efficient Drying Process

One of the standout features of Chemix's adhesive is its energy-efficient drying process, which significantly reduces energy consumption during production. This not only lowers manufacturing costs but also aligns with sustainable practices that benefit our planet. By minimizing energy use, this environmentally friendly glue supports manufacturers in their quest for greener operations while still delivering robust performance.

Strong Heat Sealing Capabilities

Chemix's water-based VC composite adhesive boasts impressive heat sealing capabilities that are crucial for ensuring the integrity of medical PVC packaging. With strong bonding glue that withstands various conditions, it provides reliable seals essential for safety and sterility in medical disposable devices. Whether used in high-demand environments or routine applications, this adhesive proves to be a dependable choice for manufacturers seeking quality and efficiency.

Conclusion

In the ever-evolving landscape of healthcare, the importance of effective adhesives cannot be overstated. As we look to the future, medical PVC packaging glue will play a pivotal role in ensuring safety and efficiency in various applications. The shift toward solvent-free adhesives is not just a trend but a necessary evolution that reflects our commitment to sustainability and patient well-being.

Future Trends in Medical Adhesives

The future of medical adhesives is bright, especially with innovations in environmentally friendly glue that cater to both performance and ecological responsibility. We can expect an increase in the use of medical disposable device adhesives that are not only strong but also safe for users and the environment. Furthermore, advancements in formulations will likely enhance the bonding capabilities of these products while maintaining compliance with stringent regulatory standards.

Why Strong Bonding Glue Matters

Strong bonding glue is essential in ensuring that medical devices function safely and effectively during their intended use. In applications like OTC packaging, where consumer safety is paramount, having reliable adhesive solutions can prevent product failures that could jeopardize health outcomes. Moreover, as we embrace new technologies and materials in PVC packaging, the demand for robust adhesive solutions will only grow stronger.

The Role of Water-Based Solutions in Healthcare

Water-based solutions are becoming increasingly vital within healthcare due to their low toxicity and reduced environmental impact compared to traditional solvents. These solvent-free adhesives not only provide excellent bonding strength but also align with modern sustainability goals across industries. As healthcare continues to prioritize eco-friendly practices, water-based options will undoubtedly lead the charge toward safer and more responsible medical packaging solutions.