Introduction

Adhesive bond strength is a critical factor in various applications, influencing everything from everyday household repairs to advanced industrial manufacturing. Understanding what adhesive bond strength entails is essential for anyone involved in selecting or utilizing adhesives. This introduction sets the stage for exploring the nuances of adhesive bond strength, including its significance and how it impacts our choices.

Understanding Adhesive Bond Strength

So, what is adhesive bond strength? At its core, it refers to the ability of an adhesive to hold materials together under stress without failing. Factors such as surface preparation, environmental conditions, and material compatibility all play a role in determining this vital characteristic.

The Role of Adhesive Strength in Industries

In industries ranging from construction to aerospace, the role of adhesive strength cannot be overstated. High adhesive bond strength ensures that components remain securely attached during operation, enhancing product reliability and safety. Consequently, understanding what is the strongest adhesive bond available helps manufacturers make informed decisions that can significantly impact their products' performance.

Why Choosing the Right Adhesive Matters

Choosing the right adhesive matters because not all adhesives are created equal; some are designed for specific applications while others offer versatility across materials. Questions like how do you calculate the strength of an adhesive bond? and what is the best adhesive for strength? become crucial when evaluating options for your project or application. Ultimately, making informed choices about adhesives can lead to improved durability and safety in products we rely on every day.

What is Adhesive Bond Strength?

When we talk about adhesive bond strength, we’re diving into the heart of how well two surfaces stick together using an adhesive. This strength is a critical factor in various applications, from crafting to heavy-duty manufacturing.

Definition of Adhesive Bond Strength

So, what is adhesive bond strength? At its core, it refers to the ability of an adhesive to hold materials together under stress without failing. This measure can vary significantly based on the type of adhesive used and the materials being bonded, making it essential for anyone working with adhesives to grasp this concept fully.

Factors Affecting Adhesive Bond Strength

Several factors can influence adhesive bond strength, and it's not just about applying glue and hoping for the best! Surface preparation plays a crucial role; clean and roughened surfaces typically enhance adhesion. Additionally, environmental conditions such as temperature and humidity can affect how well an adhesive performs, so keep these in mind when asking yourself: what is the strongest adhesive bond?

Importance in Manufacturing Processes

In manufacturing processes, understanding adhesive bond strength is paramount because it directly impacts product quality and reliability. A strong bond ensures that products withstand operational stresses without failing or degrading over time. Therefore, knowing how do you calculate the strength of an adhesive bond becomes vital for engineers striving to create durable products that meet safety standards.

What is the Strongest Adhesive Bond?

When it comes to adhesive bond strength, the quest for the strongest adhesive bond can feel like a never-ending journey through a maze of options. Different types of adhesives boast varying degrees of strength and durability, making it essential to understand their unique properties. In this section, we will delve into the world of high-strength adhesives, comparing their capabilities and exploring real-world applications that highlight their effectiveness.

Comparing Different Adhesive Types

To answer the question, What is adhesive bond strength? one must first consider the various types of adhesives available on the market. Common categories include epoxies, polyurethanes, cyanoacrylates (super glues), and silicones. Each type has its own strengths and weaknesses; for instance, epoxy resins typically offer excellent tensile strength and resistance to environmental factors, while polyurethanes are known for their flexibility and impact resistance.

When evaluating adhesive bond strength across these types, it's crucial to look at factors such as curing time, temperature resistance, and chemical compatibility. Epoxy tends to excel in static load applications due to its rigidity after curing but may lack flexibility under dynamic stress conditions. On the other hand, polyurethane adhesives shine in applications requiring movement or vibration absorption—making them a favorite in automotive or construction settings.

Applications for High-Strength Adhesives

High-strength adhesives are indispensable in industries where durability is paramount—think aerospace engineering or heavy machinery manufacturing. These environments demand not just any adhesive but ones that can withstand extreme conditions while maintaining integrity over time. For instance, when assembling aircraft components or constructing bridges, engineers often rely on adhesives with superior bond strength to ensure safety and performance.

In addition to industrial uses, high-strength adhesives find their place in everyday products like sports equipment and consumer electronics. The ability to create strong bonds without adding weight makes these adhesives ideal for lightweight designs that require both performance and aesthetics. As consumers become more aware of quality standards in products they purchase, manufacturers increasingly prioritize finding what is the best adhesive for strength.

Case Study: Epoxy vs. Polyurethane

To illustrate how different types stack up against each other regarding adhesive bond strength, let's take a closer look at epoxy versus polyurethane through a case study lens. Epoxy resins typically achieve higher tensile strengths when cured properly; however, they can become brittle under certain conditions—especially when exposed to moisture over time. This brittleness can lead to failure if not accounted for during application.

Conversely, polyurethane offers impressive flexibility alongside solid bonding capabilities; this adaptability makes it particularly effective in environments subject to thermal expansion or mechanical stress—like automotive assemblies where parts vibrate during operation. By analyzing specific scenarios where each type shines or falters helps answer How do you calculate the strength of an adhesive bond? effectively by considering both material properties and application contexts.

How Do You Calculate the Strength of an Adhesive Bond?

Calculating the strength of an adhesive bond is crucial for ensuring that your materials hold together as intended. But how do you measure this elusive quality? Let’s dive into the key metrics and testing methods that can help answer the question: How do you calculate the strength of an adhesive bond?

Key Metrics for Measuring Bond Strength

When it comes to adhesive bond strength, there are several key metrics to consider. The most common include tensile strength, shear strength, and peel strength. Each of these metrics provides insight into different aspects of how well an adhesive will perform in real-world applications, helping you determine what is the strongest adhesive bond for your needs.

Tensile strength measures how much pulling force a bonded joint can withstand before failing, while shear strength assesses resistance to sliding forces parallel to the bond line. Peel strength evaluates how well an adhesive resists forces that attempt to separate bonded materials from each other at a right angle. Understanding these metrics is essential when asking what is the best adhesive for strength in various applications.

Testing Methods: Peel and Shear Strength

To truly understand how strong your adhesive bond is, you need to employ reliable testing methods like peel and shear tests. The peel test involves applying a force at a right angle to the bonded interface until failure occurs, providing valuable data on how well two surfaces adhere under stress. On the other hand, shear tests apply a force parallel to the bonded surface, revealing insights into its performance under sliding or shearing conditions.

Both testing methods help quantify adhesive bond strength in measurable terms, allowing manufacturers and engineers to make informed decisions about which adhesives will work best in specific scenarios. By comparing results from both tests, one can better assess not only what is adhesive bond strength but also which type of adhesion offers superior performance in practical applications.

Real-World Examples of Calculating Strength

Let’s take a look at some real-world examples that illustrate calculating adhesive bond strengths effectively. For instance, consider two different adhesives used in automotive assembly: epoxy and polyurethane. When subjected to peel tests, epoxy might show higher values than polyurethane due to its rigid nature; however, polyurethane could outperform epoxy in shear tests due to its flexibility.

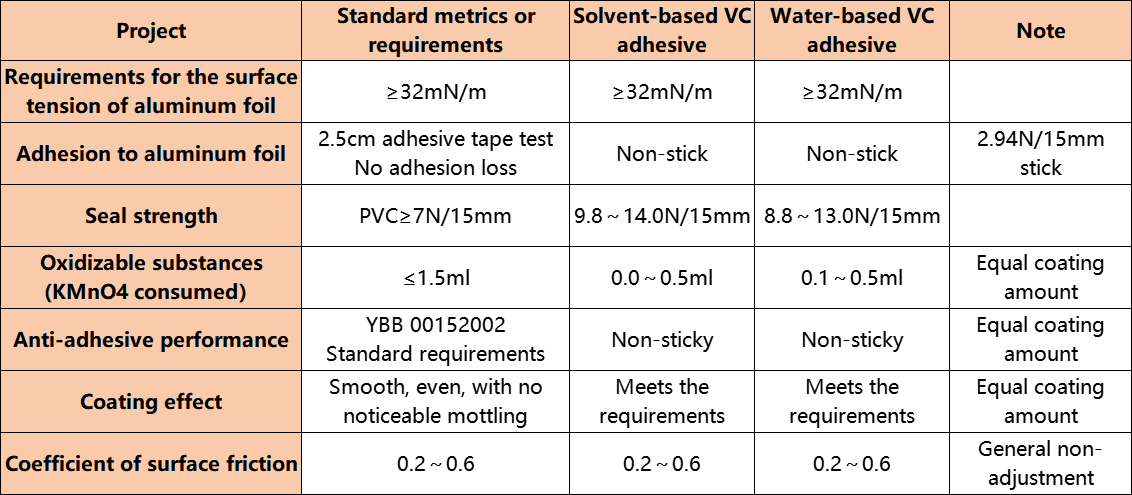

In another scenario involving construction materials like wood or metal bonding with adhesives designed for heavy-duty use—such as Chemix's water-based VC composite—calculating their strengths through standardized tests reveals critical insights into durability and longevity under stress conditions. These examples highlight not just what is the strongest adhesive bond but also emphasize why understanding these calculations matters significantly when choosing adhesives tailored for specific projects or environments.

What is the Best Adhesive for Strength?

When it comes to achieving optimal adhesive bond strength, selecting the right adhesive is crucial. There’s a myriad of options available, each tailored for specific applications and environments. In this section, we’ll explore some of the top adhesives for heavy-duty use and highlight Chemix's innovative water-based VC Composite Adhesive.

Overview of Top Adhesives for Heavy-Duty Use

In the realm of high-strength adhesives, several contenders stand out as champions in durability and reliability. Epoxy adhesives are renowned for their exceptional adhesive bond strength and versatility in various applications, making them a go-to choice in construction and automotive industries. Polyurethane adhesives also deserve mention; they offer impressive flexibility along with strong adhesion, making them suitable for materials that experience movement or stress.

Another notable mention is cyanoacrylate glue, widely recognized as super glue, which can create incredibly strong bonds quickly but may not be ideal for all heavy-duty applications due to its brittleness over time. For those looking at industrial-grade solutions, structural acrylics provide an outstanding balance of speed and strength that can withstand harsh conditions. Ultimately, the best adhesive will depend on specific project requirements—whether you need instant bonding or long-lasting durability.

Spotlight on Chemix's Water-based VC Composite Adhesive

Among the plethora of options available today, Chemix's water-based VC Composite Adhesive shines brightly due to its unique formulation designed specifically for high-performance bonding needs. This adhesive not only boasts impressive adhesive bond strength but also offers excellent resistance to moisture and environmental factors—making it a perfect fit for both indoor and outdoor applications. What sets it apart is its eco-friendly nature; being water-based means fewer volatile organic compounds (VOCs), promoting safety without sacrificing performance.

Chemix’s VC Composite Adhesive excels particularly in applications involving wood composites and laminates where traditional adhesives might struggle under stress or exposure to moisture. Its versatility allows it to perform well across various substrates while ensuring that your projects remain resilient over time. If you’re pondering what is the best adhesive for strength in eco-conscious projects without compromising on durability, this product certainly deserves your attention.

Benefits of Choosing a Strong Adhesive

Understanding how do you calculate the strength of an adhesive bond becomes essential when selecting an adhesive suited to your needs; however, starting with a strong option simplifies this process significantly! Strong adhesives like those mentioned earlier not only enhance product durability but also reduce risks associated with weak bonds that can lead to failures or accidents over time. By investing in robust solutions like Chemix’s VC Composite Adhesive or epoxy variants, you're ensuring peace of mind knowing your bonds will hold up under pressure.

Moreover, choosing a strong adhesive translates into long-term cost savings by minimizing maintenance and repair expenses associated with weaker alternatives that may fail prematurely. In high-stress environments where safety is paramount—think construction sites or automotive assembly lines—having reliable adhesion becomes non-negotiable if you wish to avoid catastrophic failures down the line. So remember: when considering what is the strongest adhesive bond? Look no further than those designed explicitly for heavy-duty use!

The Impact of Adhesive Strength on Safety

Adhesive bond strength is not just a technical specification; it plays a crucial role in ensuring product durability and safety across various industries. When an adhesive bond fails, the consequences can range from minor inconveniences to catastrophic failures, especially in high-stress environments where safety is paramount. Understanding how adhesive strength impacts product longevity can help manufacturers make more informed choices about what is the best adhesive for strength.

Adhesive Strength and Product Durability

The relationship between adhesive bond strength and product durability cannot be overstated. A strong adhesive bond ensures that materials remain securely attached over time, resisting environmental factors such as temperature fluctuations, moisture, and chemical exposure. In applications where durability is essential, understanding what is adhesive bond strength becomes critical for selecting the right products that will withstand wear and tear.

Ensuring Safety in High-Stress Environments

In high-stress environments—like aerospace, automotive manufacturing, or construction—adhesive bond strength takes center stage in safeguarding both people and equipment. Here, the stakes are high; a weak adhesive could lead to structural failures or accidents that endanger lives and property. Therefore, calculating the strength of an adhesive bond accurately using methods like peel and shear tests is vital for ensuring safety standards are met.

Real-Life Scenarios: Failures Due to Weak Bonds

There are numerous real-life scenarios where inadequate adhesive bond strength has led to serious failures. For instance, consider a bridge constructed with subpar adhesives; one day it might simply collapse under stress due to weak bonds that couldn’t hold up against environmental pressures or loads. Such incidents highlight the importance of knowing what is the strongest adhesive bond available for critical applications—because when lives are on the line, you can't afford to compromise on quality.

Conclusion

In the world of manufacturing and construction, understanding adhesive bond strength is crucial. The strength of these bonds determines the durability and reliability of products, making it essential to choose the right adhesive for specific applications. As we wrap up our exploration, it's clear that strong adhesive bonds are not just a technical detail; they are fundamental to safety and performance across various industries.

The Importance of Strong Adhesive Bonds

Strong adhesive bonds play a pivotal role in ensuring product integrity and longevity. When we ask ourselves, What is adhesive bond strength? it becomes evident that this characteristic can significantly impact everything from consumer goods to aerospace components. Weak bonds can lead to catastrophic failures, underscoring the importance of selecting adhesives that meet rigorous strength requirements.

Making Informed Choices in Adhesives

With myriad options available on the market, knowing how to make informed choices about adhesives is vital for anyone involved in product design or engineering. Questions like What is the best adhesive for strength? often arise when selecting materials for demanding applications. By understanding factors that influence adhesive bond strength and evaluating different types—like epoxies or polyurethanes—professionals can ensure they select the most suitable products for their needs.

Future Trends in Adhesive Technology

Looking ahead, trends in adhesive technology promise exciting advancements aimed at enhancing adhesive bond strength even further. Innovations such as bio-based adhesives and smart adhesives with self-healing properties are on the horizon, potentially transforming industries by providing stronger and more sustainable solutions. As we continue to innovate, understanding how to calculate the strength of an adhesive bond will remain essential in harnessing these new technologies effectively.