Introduction

Blister packs have become a staple in packaging, offering both protection and convenience for a variety of products. At the heart of this innovative packaging solution lies blister pack adhesive, which plays a crucial role in ensuring that the contents remain secure and intact until they reach the consumer. Understanding what is blister pack adhesive and its importance can help manufacturers make informed choices that enhance product safety and user experience.

Understanding Blister Pack Adhesives

Blister pack adhesives are specifically formulated substances used to bond the blister (the plastic compartment) to the backing material, typically made of paper or foil. Their functionality goes beyond mere adhesion; they must also withstand various environmental factors such as humidity and temperature fluctuations while maintaining their integrity over time. By grasping what is blister pack adhesive, companies can select formulations that meet their specific needs, improving overall product quality.

Importance of Choosing the Right Adhesive

Selecting the right adhesive for blister packs is essential not only for product safety but also for consumer convenience. A poor choice could lead to compromised seals, resulting in damaged products or even contamination—definitely not ideal! Moreover, understanding how are blister packs sealed helps manufacturers appreciate how critical adhesives are in maintaining an effective seal that protects against external elements.

Overview of the Blister Pack Packaging Process

The process of creating blister packs involves several steps: forming the plastic blisters, filling them with products, sealing them with backing material, and ensuring everything stays put through proper adhesive application. Each stage requires careful consideration to ensure optimal performance; otherwise, you might find yourself questioning what is a blister pack used for if it doesn’t do its job properly! Additionally, knowing what is the alternative to blister packs can provide insights into whether this method remains superior for specific applications or if other options might serve better.

What is Blister Pack Adhesive?

Blister pack adhesive plays a crucial role in the world of packaging, particularly for products that require protection and easy access. It is specifically designed to bond the plastic blister to the backing material, which can be cardboard or foil. Understanding what blister pack adhesive is and how it functions is essential for anyone involved in packaging design and production.

Definition and Functionality

So, what is blister pack adhesive? Simply put, it's a type of adhesive formulated to securely seal products within a blister package while ensuring they remain visible and accessible. Its primary function is to provide a strong bond that withstands various environmental conditions, such as temperature fluctuations and humidity. This functionality not only protects the product but also enhances consumer convenience by allowing easy peeling or pushing through the package.

Applications in Various Industries

Blister pack adhesives are versatile and find applications across multiple industries. From pharmaceuticals, where they securely package tablets and capsules, to consumer goods like batteries or small electronics, these adhesives are everywhere! The ability to keep items safe while being displayed prominently makes them invaluable in retail settings as well.

In addition to pharmaceuticals and consumer goods, blister packs are also used in food packaging—think of those snack-sized portions you pop open with ease! The food industry benefits from these adhesives because they help preserve freshness while providing tamper-proof seals that enhance safety. Knowing what a blister pack is used for underscores its importance across various sectors.

Key Properties to Consider

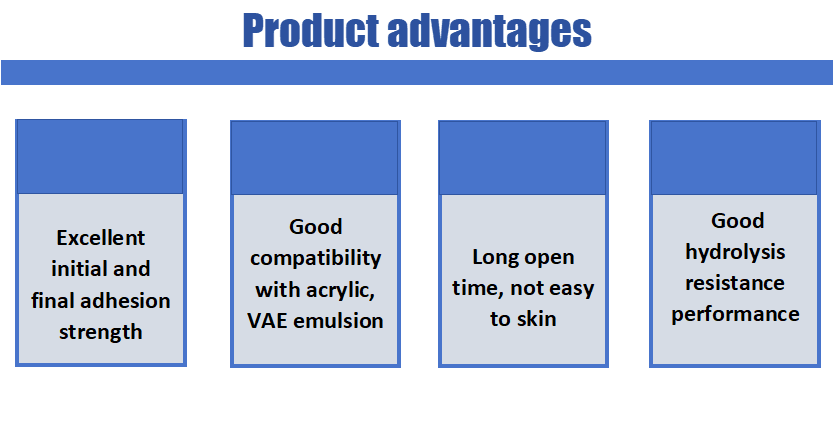

When selecting an adhesive for blister packs, several key properties should be taken into account. First off, adhesion strength is paramount; you want your product securely sealed without risk of accidental opening during transport or handling. Additionally, consider factors such as flexibility—after all, some products might need to be pushed through the packaging—and resistance to moisture or chemicals.

Another important aspect involves compatibility with both materials involved: the blister itself and the backing layer. If you're pondering how are blister packs sealed so effectively? It’s largely due to choosing the right adhesive that ensures optimal bonding between different surfaces under various conditions. Ultimately, understanding these key properties can lead you toward making informed decisions about what type of blister pack adhesive will best suit your needs.

What is a Blister Pack Used For?

Blister packs are versatile packaging solutions that serve a wide range of products across various industries. From pharmaceuticals to consumer goods, these packs are designed to protect and display items while ensuring convenience for users. Understanding what a blister pack is used for can help businesses make informed decisions about their packaging needs.

Common Products and Uses

Blister packs are predominantly used in the pharmaceutical industry for medications such as tablets and capsules, providing an effective barrier against moisture and contamination. Beyond medicine, they also house consumer products like batteries, tools, and even food items—think of those delightful single-serving cheese spreads! The versatility of blister pack adhesive allows manufacturers to tailor the packaging to meet specific requirements while maintaining product integrity.

Advantages of Blister Packaging

One of the key advantages of blister packaging is its ability to extend shelf life by protecting products from environmental factors such as humidity and light. Additionally, it offers excellent visibility—consumers can see exactly what they’re purchasing without compromising security or freshness. With efficient use of materials leading to reduced waste, it's no wonder that many companies are opting for blister packs over traditional packaging methods.

Consumer Safety and Convenience

When considering what a blister pack is used for, consumer safety plays a crucial role in its appeal. The secure sealing methods employed ensure that products remain tamper-proof until opened, giving consumers peace of mind about their purchases. Moreover, blister packs often feature easy-to-push designs that enhance user convenience—perfect for those moments when you need just one pill or snack!

How are Blister Packs Sealed?

Blister packs are a staple in packaging, particularly for pharmaceuticals and consumer goods. Understanding how they are sealed is crucial for ensuring product integrity and safety. The sealing process involves various techniques that leverage the properties of blister pack adhesive to create a secure barrier.

Sealing Techniques Explained

Heat sealing uses temperature to bond the lid material to the blister base, creating a tamper-evident seal that is hard to break without damaging the pack. Cold sealing employs pressure-sensitive adhesives that activate upon contact, allowing for quick assembly without the need for heat—ideal for sensitive products.

Understanding how these different methods work can help answer the question: what is a blister pack used for? Each technique has its own set of applications based on product requirements and consumer preferences. For instance, heat-sealed packs are commonly used in pharmaceuticals where sterility is paramount.

Role of Adhesives in Sealing

Adhesives play a pivotal role in ensuring that blister packs remain intact until they reach consumers. What is blister pack adhesive? Essentially, it’s a specialized glue designed to bond various materials—like plastic foils and paper—used in packaging. The choice of adhesive affects not only the strength of the seal but also its ability to withstand environmental factors like humidity and temperature.

In addition to providing an airtight seal, adhesives also contribute to the overall aesthetic appeal of the packaging by allowing for clear visibility of the product inside while maintaining tamper-proof characteristics. This makes them essential when considering what is a blister pack used for in terms of both functionality and marketing appeal.

Importance of Proper Sealing

Proper sealing isn’t just about aesthetics; it’s crucial for consumer safety and product longevity. An improperly sealed blister pack can lead to contamination or spoilage, which raises questions about what is the alternative to blister packs when looking at safer options available on the market today. Furthermore, inadequate seals can result in wasted products—a costly affair for manufacturers aiming to maintain their bottom line.

Moreover, understanding what is the difference between strip pack and blister pack becomes vital here; while both serve similar purposes in packaging individual doses or items, their sealing methods significantly impact their effectiveness and suitability depending on product type. Therefore, investing time into mastering proper sealing techniques using high-quality adhesives ensures that products remain safe and effective from production through consumption.

What is the Alternative to Blister Packs?

When it comes to packaging, blister packs are a popular choice, but they aren't the only option available. Alternatives like clamshell packaging, shrink wraps, and cartons each have their unique features and benefits. Understanding these alternatives can help businesses determine what is best suited for their products while considering factors such as cost, protection, and consumer appeal.

Comparison with Alternative Packaging

Clamshell packaging is a common alternative to blister packs that provides visibility while protecting products. Unlike blister packs that often use specific adhesives for sealing, clamshells rely on plastic hinges and locking mechanisms to keep items secure. Shrink wraps offer another option by tightly encasing products in a thin plastic film that shrinks when heated—this method is often used for bulk items or multi-pack offerings.

Cartons provide yet another alternative; they are typically made from cardboard or paperboard and can be printed with vibrant graphics to enhance branding. While blister packs excel in showcasing individual items and providing tamper resistance, cartons can offer more space for information and branding opportunities. Each of these alternatives has its own set of advantages depending on what is a blister pack used for—be it pharmaceuticals or consumer goods.

Pros and Cons of Other Options

When evaluating alternatives to blister packs, it's essential to weigh the pros and cons of each option carefully. For instance, clamshells offer excellent visibility but may not be as eco-friendly as blister packs if not made from recyclable materials. On the other hand, shrink wraps are often less expensive but might not provide the same level of protection against damage during transportation.

Cartons can be cost-effective and customizable but may lack the tamper-evidence feature that some consumers prefer in blister packaging. Additionally, while blister packs are known for their durability due to strong adhesives that ensure proper sealing (which ties into how are blister packs sealed?), some alternatives might require extra measures to achieve similar levels of security against product tampering or contamination.

Market Trends in Packaging Solutions

The market for packaging solutions continues evolving as companies seek innovative ways to stand out while being environmentally conscious. There's a growing trend toward sustainable options across all types of packaging—including alternatives to blister packs—that minimize environmental impact without sacrificing quality or performance. As consumers become more aware of sustainability issues, brands are increasingly exploring eco-friendly materials that align with this shift.

Moreover, advancements in technology have led to improved adhesive formulations across various types of packaging solutions—making them more efficient than ever before when sealed properly (and yes, this relates back to how are blister packs sealed?). As businesses consider what is the alternative to blister packs for their products moving forward, staying informed about these trends will be crucial in making informed choices about their packaging strategies.

What is the Difference Between Strip Pack and Blister Pack?

When it comes to packaging, understanding the differences between strip packs and blister packs can make a world of difference for manufacturers and consumers alike. Both types serve unique purposes and are widely used in various industries, particularly in pharmaceuticals and consumer goods. But what is blister pack adhesive's role in these two formats? Let’s dive into the definitions, strengths, limitations, and when to choose one over the other.

Definitions and Use Cases

A blister pack is a pre-formed plastic packaging that houses individual items securely within cavities or blisters. Typically sealed with a backing material like paper or foil, it’s often used for medications, vitamins, and small consumer products. On the other hand, a strip pack consists of a flexible film that contains multiple doses of medication or products sealed between layers of material; it's commonly used for single-dose applications like tablets or capsules.

While both packaging types aim to protect their contents from external factors like moisture or contamination, their use cases vary significantly. For instance, blister packs are ideal for items requiring visibility while still providing tamper resistance—think about how you can see your favorite pain reliever through its clear plastic surface! Strip packs shine when convenience is key; they allow quick access to single doses without any fuss.

Strengths and Limitations of Each Type

Blister packs come with several advantages: they offer excellent product visibility, longer shelf life due to airtight seals, and customizable designs that can enhance branding efforts. However, these benefits come at a cost—blister packs can be more expensive to produce compared to strip packs due to their complex manufacturing processes involving adhesives and sealing techniques.

Strip packs have their own set of strengths as well; they are typically easier to manufacture and require less material than blister packs. This makes them more cost-effective for high-volume production runs. Nevertheless, strip packs may not provide as much protection against environmental factors as blister packs do since they rely on heat sealing rather than robust adhesives like those used in blister packaging.

When to Choose One Over the Other

Choosing between blister packs and strip packs largely depends on your specific needs regarding product safety, visibility, cost-effectiveness, and user convenience. If you’re dealing with sensitive medications that require maximum protection from moisture or tampering—what is a blister pack used for?—then opting for a blister pack would be wise due to its superior sealing capabilities.

Conversely, if your product is designed for quick consumption where ease-of-access is paramount—considering what is the alternative to blister packs—you might lean towards using strip packaging instead. Ultimately, understanding what each type offers will help you make informed choices about which packaging solution best fits your product's requirements.

Eco-Friendly Adhesive Solutions

In the world of packaging, the quest for sustainability has led to innovative solutions, particularly in adhesive technologies. Chemix's water-based VC composite adhesive stands out as a prime example of eco-friendly options that cater to modern packaging needs. This adhesive not only meets performance standards but also aligns with environmental goals, making it an attractive choice for businesses looking to minimize their ecological footprint.

Introduction to Chemix's Water-based VC Composite Adhesive

Chemix's water-based VC composite adhesive is designed specifically for blister pack applications, providing a robust solution without compromising on safety or efficacy. Unlike traditional solvent-based adhesives, this product uses water as a primary solvent, reducing harmful emissions and promoting a healthier working environment. By integrating advanced technology with sustainable practices, Chemix offers an innovative way to address the question: what is blister pack adhesive that is both effective and environmentally friendly?

Benefits of Using Water-based Adhesives

Water-based adhesives come with a plethora of benefits that make them increasingly popular in various industries. First and foremost, they are less toxic than their solvent counterparts, which translates into improved safety for workers and consumers alike—especially when considering what is a blister pack used for? Additionally, these adhesives provide excellent bonding strength and flexibility while being easier to clean up and handle during production processes. Ultimately, opting for water-based adhesives can enhance product quality while contributing positively to environmental sustainability.

Environmental Impact of Packaging Choices

The environmental impact of packaging choices cannot be overstated; every decision we make reverberates through ecosystems worldwide. By utilizing eco-friendly options like Chemix's water-based VC composite adhesive, companies can significantly reduce waste and pollution associated with traditional packaging methods—addressing concerns about how are blister packs sealed? Moreover, sustainable practices in packaging not only cater to consumer demand but also align with regulatory trends pushing for greener alternatives across various sectors. As more businesses evaluate what is the alternative to blister packs or consider what is the difference between strip pack and blister pack solutions, it becomes clear that eco-conscious choices are shaping the future landscape of packaging.

Conclusion

In summary, blister pack adhesives play a critical role in the packaging industry by ensuring that products are securely sealed and protected. Understanding what is blister pack adhesive, its applications, and how it contributes to the overall functionality of blister packs is essential for manufacturers. With advancements in technology and materials, choosing the right adhesive can enhance product safety, consumer convenience, and sustainability.

Key Takeaways on Blister Pack Adhesives

When exploring what is a blister pack used for?, it’s clear that these packages serve various industries from pharmaceuticals to consumer goods. The key properties of blister pack adhesives include adhesion strength, temperature resistance, and compatibility with different materials. Additionally, knowing how are blister packs sealed helps manufacturers ensure product integrity while maintaining user-friendly designs.

Future Trends in Blister Packaging

The future of blister packaging looks promising with a shift towards sustainable solutions; eco-friendly alternatives are becoming more prevalent in response to environmental concerns. Innovations in adhesive technology will likely focus on reducing waste and enhancing recyclability while still providing the necessary protection for products. Moreover, understanding what is the alternative to blister packs will help businesses stay competitive by offering diverse packaging options that meet evolving consumer preferences.

Making Informed Choices in Packaging Solutions

Choosing between blister packs or strip packs can be crucial for your product's success; understanding what is the difference between strip pack and blister pack will guide you through this decision-making process. Considerations such as cost-effectiveness, ease of use, and consumer appeal should influence your choice of packaging solution. Ultimately, making informed choices about adhesives and packaging types will not only improve product presentation but also enhance customer satisfaction.