Introduction

Understanding the Importance of Adhesives

Adhesives are more than just sticky substances; they are critical components that bind various materials together, especially in packaging applications. Choosing the best adhesive for PVC sheet can significantly affect not only the durability but also the aesthetic appeal of your product's packaging. Whether you're using PVC adhesive or PVC trim adhesive, it's important to recognize how these choices impact overall performance and functionality.

Types of Packaging Materials

The world of packaging materials is vast and varied, encompassing everything from cardboard to plastic films and glass containers. Among these materials, PVC stands out due to its versatility and durability, making it a popular choice for many manufacturers. When selecting a suitable adhesive—like PVC Adhesive Tape—it's crucial to consider how well it interacts with your chosen material to achieve optimal results.

Choosing the Right Adhesive

Selecting an adhesive isn't just about grabbing any tube off the shelf; it's about understanding compatibility with your specific materials and application needs. The best adhesive for PVC sheet should be chosen based on factors such as bond strength, drying time, and environmental conditions during application. By carefully evaluating options like PVC trim adhesive or other specialized adhesives, you can ensure your packaging not only looks great but also performs exceptionally well throughout its lifecycle.

PVC Packaging Adhesives: The Best Choices

Finding the best adhesive for PVC sheet can feel like searching for a needle in a haystack, but fear not! Some of the top contenders include solvent-based adhesives, cyanoacrylate glues, and specialized PVC adhesive tapes. These options offer excellent bonding capabilities while ensuring that your packages remain intact during transport and storage.

Solvent-based adhesives are ideal when you need a strong bond quickly; they penetrate the material well and create a lasting hold. Cyanoacrylate glues are perfect for smaller applications where precision is key, providing fast-drying results that won't leave you hanging. Finally, if you're looking for ease of use combined with efficiency, PVC adhesive tape may just be your new best friend!

Key Features of PVC Trim Adhesive

PVC trim adhesive is specially formulated to bond trim pieces securely without compromising their appearance or functionality. One of its standout features is its flexibility; it allows for movement without cracking or breaking away from the surface over time. This characteristic makes it an excellent choice not just for packaging but also in various construction applications.

Another key feature is its resistance to moisture and temperature fluctuations, ensuring that your bonds remain strong under varying conditions. Additionally, many high-quality PVC trim adhesives are designed to dry clear, providing a clean finish that won't detract from your overall design aesthetic. When selecting a PVC trim adhesive, make sure to consider these features to ensure optimal performance.

Benefits of PVC Adhesive Tape

PVC adhesive tape offers numerous advantages that make it an attractive option in packaging solutions. First off, its ease of application cannot be overstated; simply peel off the backing and stick—no mess or complicated processes involved! This simplicity means you can save time during production while still achieving reliable results.

Moreover, this type of tape boasts excellent adhesion properties on various surfaces beyond just PVC—making it incredibly versatile in different applications. Additionally, many varieties are resistant to chemicals and UV light exposure which ensures longevity even in challenging environments! Ultimately, switching to high-quality PVC adhesive tape could streamline your operations while providing superior bonding strength.

Eco-Friendly Options: Chemix's Water-Based VC Composite Adhesive

In the ever-evolving world of packaging, eco-friendly options are gaining traction, and Chemix's water-based VC composite adhesive is leading the charge. This innovative adhesive not only meets the demands of modern packaging but also aligns with sustainability goals. With its versatility, it's becoming a popular choice for those seeking the best adhesive for PVC sheet applications.

Advantages of Using Water-Based Adhesives

Water-based adhesives offer a plethora of advantages over their solvent counterparts, making them a go-to choice for many in the packaging industry. First and foremost, they are significantly less harmful to both human health and the environment; you can say goodbye to harsh fumes and toxic chemicals! Additionally, using a PVC trim adhesive like Chemix’s can enhance adhesion properties while ensuring that your operations remain compliant with environmental regulations.

Another perk is their ease of cleanup—no more scrubbing away stubborn residues or dealing with hazardous waste disposal! Water-based adhesives also exhibit excellent bonding strength on various materials, including PVC, which makes them incredibly versatile. As businesses become more conscientious about their ecological footprint, choosing products like PVC adhesive tape becomes not just an option but a responsibility.

Application and Handling Tips

When applying Chemix's water-based VC composite adhesive, there are some key tips to keep in mind to ensure optimal performance. First off, always make sure surfaces are clean and free from dust or grease; this simple step can dramatically improve adhesion quality for your PVC packaging adhesive needs.

Temperature and humidity play crucial roles during application as well; aim for conditions that fall within recommended ranges specified by the manufacturer to avoid issues like slow curing or poor bonding. Once applied, allow sufficient time for curing before subjecting your projects to stress or load—this ensures that your PVC trim adhesive reaches its full potential! Lastly, don’t forget about safety: even though these adhesives are eco-friendly, wearing gloves is always a smart move when handling any type of glue.

Comparisons with Traditional Solvent-Based Adhesives

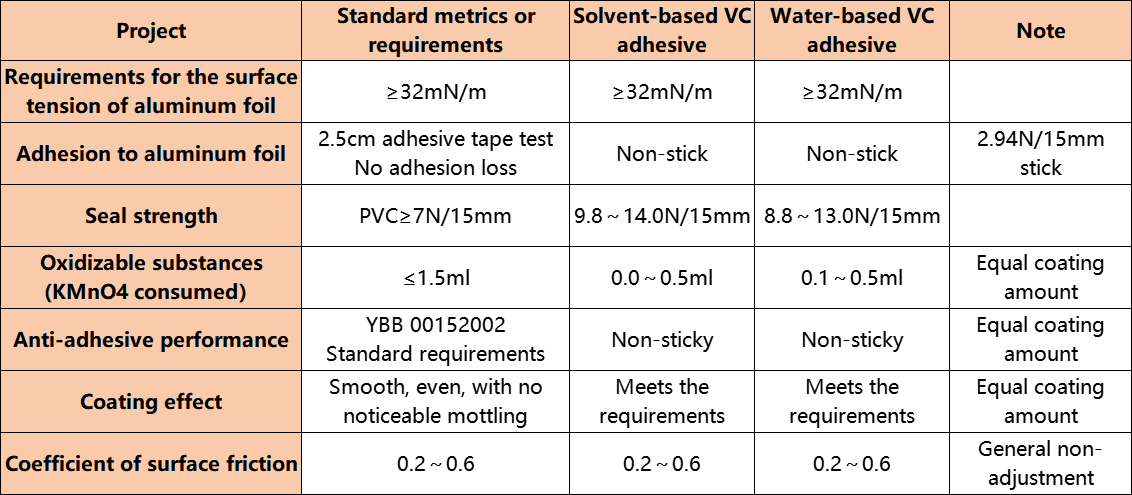

When you stack water-based adhesives against traditional solvent-based options like typical PVC adhesives or even heavy-duty industrial solutions, the differences become glaringly obvious. While solvent-based adhesives may offer strong initial bonds and quick drying times, they often come at the cost of environmental safety and user health—a trade-off that's increasingly hard to justify in today's market. In contrast, Chemix's water-based offerings provide comparable bonding strength without compromising on sustainability.

Moreover, traditional options often require special ventilation systems due to their volatile organic compounds (VOCs), whereas water-based alternatives can be safely used in various settings without such concerns—making them ideal for both small workshops and large-scale production facilities alike! Additionally, as consumers lean towards greener products in every sector—from food packaging to consumer goods—the demand for eco-friendly solutions like PVC Adhesive Tape continues to rise exponentially.

In summary? While solvent-based options have held sway in the past due to perceived performance benefits, innovations like Chemix’s water-based VC composite adhesive demonstrate that going green doesn’t mean sacrificing quality—it means elevating it!

Industrial Adhesives for Heavy-Duty Packaging

Best Industrial Strength Adhesives

For those in search of the best adhesive for PVC sheet applications, several standout options exist in the market. One popular choice is polyurethane-based adhesives, known for their exceptional bonding strength and flexibility. Additionally, epoxy resins also provide robust adhesion and durability, making them ideal for heavy-duty applications where PVC trim adhesive is required.

PVC adhesive tape is another remarkable option that combines ease of use with industrial-grade strength. This type of tape not only adheres well to various surfaces but also offers excellent resistance to moisture and temperature fluctuations. Selecting the right product from this array ensures that your packaging remains secure under even the most demanding conditions.

Performance Metrics to Consider

When evaluating industrial adhesives for heavy-duty packaging, several performance metrics should guide your decision-making process. First and foremost, tensile strength indicates how much force an adhesive can withstand before failing; higher values are preferable for heavy-duty applications using PVC packaging adhesive or similar materials.

Another critical metric is curing time; a faster cure means quicker turnaround times without compromising bond quality—perfect when you’re racing against deadlines! Finally, consider environmental resistance factors such as moisture and temperature stability; these will determine how well your chosen adhesive performs under various conditions.

Case Studies of Success

Numerous companies have successfully implemented industrial adhesives into their heavy-duty packaging processes with impressive results. For instance, a leading electronics manufacturer switched to a high-performance PVC trim adhesive for their product casing needs and saw a 30% reduction in returns due to damaged shipments—a win-win situation!

Similarly, a beverage company adopted PVC adhesive tape in their bottling line which enhanced their operational efficiency by minimizing downtime related to seal failures during transit. These case studies highlight how selecting the right industrial-strength adhesives can lead not only to better product protection but also significant cost savings over time.

Specialty Adhesives for Unique Materials

When it comes to packaging, not all materials are created equal. Specialty adhesives play a crucial role in ensuring that unique materials like glass and metal are securely bonded, providing both functionality and aesthetic appeal. Understanding the right adhesive for these unconventional materials can elevate your packaging game and ensure durability.

Adhesives for Glass and Metal Packaging

Glass and metal present distinct challenges when it comes to bonding, but fear not—there are specialized adhesives designed specifically for these surfaces. For glass packaging, a high-quality PVC packaging adhesive is often recommended due to its strong bond and clarity, making it ideal for transparent applications. Similarly, when working with metal, choosing the best adhesive for PVC sheet applications ensures that the bond withstands environmental stressors without compromising integrity.

These adhesives typically feature fast curing times and resistance to moisture and temperature fluctuations, which is essential in maintaining product quality over time. Additionally, using PVC trim adhesive can enhance aesthetic aspects by providing clean lines without visible glue marks or residues on finished products. When selecting an adhesive for glass or metal packaging, it's important to consider both performance characteristics and ease of application.

Addressing Challenges with Non-Conventional Materials

Working with non-conventional materials often requires a different approach than traditional substrates like paper or cardboard. One common challenge is ensuring adhesion without damaging delicate surfaces; this is where specialty adhesives come into play as they offer tailored solutions. For instance, when using PVC adhesive tape on irregularly shaped items or surfaces that require flexibility during application, you gain versatility while maintaining strong bonds.

Another challenge lies in surface preparation; many non-conventional materials need specific treatments before applying any PVC packaging adhesive to ensure optimal adhesion properties. Factors such as surface cleanliness and texture can significantly impact performance outcomes; thus understanding these requirements is key in avoiding mishaps down the line. By addressing these challenges head-on with the right specialty adhesives, you can achieve superior results even in tricky circumstances.

Innovations in Specialty Adhesives

The world of specialty adhesives is constantly evolving as new technologies emerge to meet ever-changing market demands. Recent innovations include advanced formulations that provide enhanced bonding capabilities while being environmentally friendly—a win-win situation! For example, some new PVC trim adhesive options boast improved flexibility and resistance to UV light exposure compared to their predecessors.

Moreover, manufacturers are now producing multi-purpose specialty adhesives that cater to various materials beyond just glass or metal—think plastics combined with wood! This versatility opens up endless possibilities in design while simplifying inventory management since fewer types of adhesives are needed overall. As we look ahead at future trends within this sector, expect even more groundbreaking developments aimed at enhancing efficiency without sacrificing quality.

Common Mistakes When Choosing Adhesives

Choosing the right adhesive can feel like navigating a maze, especially with the myriad of options available. Many users stumble into common pitfalls that can lead to poor performance and frustrating results. Understanding these mistakes is crucial for selecting the best adhesive for PVC sheet and ensuring your projects succeed.

Misunderstanding Adhesive Compatibility

One of the most frequent missteps in adhesive selection is misunderstanding compatibility between materials. Not all adhesives work well with every type of plastic or surface, which can lead to delamination or failure in bonding. For instance, while PVC packaging adhesive is excellent for PVC materials, it may not adhere well to other substrates like metal or glass without proper preparation.

When considering a PVC trim adhesive, it's vital to check if it's specifically formulated for the intended application. Many assume any strong adhesive will do, but using a product not designed for PVC can result in weak bonds and costly rework. Always consult product specifications and manufacturer recommendations to avoid this compatibility conundrum.

Underestimating Cure Times

Another common error is underestimating cure times associated with different adhesives. While some adhesives may set quickly, others require longer periods to achieve full strength—especially when dealing with PVC adhesive tape or similar products. Rushing this process can lead to premature failures in packaging integrity.

For best results, always refer to the manufacturer's guidelines regarding cure times for your chosen PVC packaging adhesive. It's essential to allow sufficient time before subjecting the bond to stress or load; doing so ensures that you get the most out of your chosen adhesive solution. Patience pays off—after all, no one wants their hard work undone because they couldn't wait a few extra hours!

Ignoring Environmental Conditions

Lastly, ignoring environmental conditions during application can spell disaster for any bonding project involving adhesives like PVC trim adhesive or general-purpose PVC adhesives. Factors such as temperature and humidity play significant roles in how well an adhesive performs; extreme conditions can compromise adhesion quality and longevity.

Before applying any PVC packaging adhesive, assess your workspace's environment carefully—if it’s too cold or damp, consider postponing until conditions improve or using heaters/dehumidifiers as necessary. Additionally, ensure that surfaces are clean and dry before application; even minor contaminants can hinder bond strength significantly! Remember: a little prep goes a long way toward achieving durable results.

Conclusion

In the world of packaging, choosing the right adhesive can make or break your project. From PVC packaging adhesive to specialty adhesives for unique materials, there are options tailored for every need. Understanding the best adhesive for PVC sheet applications and other materials ensures durability and effectiveness in your packaging solutions.

Summary of Best Adhesives for Packaging

When it comes to selecting adhesives, PVC trim adhesive stands out as a top choice for its versatility and strength. Additionally, PVC adhesive tape offers an easy-to-use solution that excels in bonding various surfaces while providing flexibility. Ultimately, the best adhesive for PVC sheet applications will depend on specific project requirements, but knowing your options will empower you to make informed decisions.

Importance of Selecting the Right Adhesive

Selecting the right adhesive is crucial not only for ensuring strong bonds but also for enhancing overall product integrity and performance. Using an inappropriate PVC packaging adhesive can lead to failures and increased costs down the line due to rework or product returns. By carefully considering factors such as material compatibility and environmental conditions, you can avoid common pitfalls that arise from poor adhesive choices.

Future Trends in Packaging Adhesives

As sustainability becomes increasingly important in packaging design, eco-friendly options like water-based adhesives are gaining traction among manufacturers. Innovations in formulations will likely lead to more efficient PVC adhesives that minimize environmental impact without sacrificing performance. The future of packaging adhesives promises exciting developments that prioritize both functionality and ecological responsibility.