Introduction

In the ever-evolving world of packaging, the emergence of PVC blister pack adhesive has revolutionized how products are secured and presented. With a unique combination of strength and flexibility, these adhesives have become indispensable in various industries, ensuring that goods remain intact while also appealing to consumers. As companies strive for more effective packaging solutions, understanding the nuances of PVC film for blister packaging adhesive is essential.

The Rise of Blister Glue in Packaging

Blister glue has seen a meteoric rise in popularity thanks to its ability to create secure seals that protect products from contamination and damage. This type of adhesive is particularly favored in sectors like pharmaceuticals, where maintaining product integrity is paramount; hence, PVC pharmaceutical packaging adhesive has become a standard choice for many manufacturers. The versatility and reliability of blister glue have made it integral to modern packaging strategies across diverse markets.

What Makes Durable Adhesives Essential

Durable adhesives are crucial not only for maintaining product safety but also for enhancing user experience through easy opening and resealing options. With consumers increasingly concerned about sustainability and environmental impact, water-based adhesive solutions have gained traction as eco-friendly alternatives without compromising performance. By choosing the right PVC packaging adhesive, businesses can ensure their products stand out while meeting regulatory compliance and consumer expectations.

Exploring PVC Packaging Adhesives

PVC packaging adhesives offer a range of benefits over traditional options, including superior bonding strength and resistance to moisture and temperature fluctuations. These properties make them ideal for various applications beyond just blister packs, such as food packaging and consumer goods. By delving into the specifics of PVC film for blister packaging adhesive, companies can better understand how these materials contribute to innovative solutions in today's competitive marketplace.

Understanding PVC Blister Pack Adhesives

When it comes to packaging, PVC blister pack adhesive is a game changer, especially in the world of consumer goods and pharmaceuticals. This adhesive type provides a robust bond that ensures product safety and longevity while maintaining aesthetic appeal. The unique properties of PVC film for blister packaging adhesive make it an ideal choice for various applications across industries.

Properties of PVC Film for Blister Packaging Adhesive

PVC film for blister packaging adhesive boasts remarkable clarity and strength, making it perfect for showcasing products while providing a reliable seal. Its flexibility allows it to conform to various shapes, ensuring that even irregularly shaped items are securely packaged. Furthermore, the chemical resistance of PVC film enhances its durability against environmental factors, which is crucial in maintaining product integrity.

Applications in Various Industries

The versatility of PVC packaging adhesive extends across multiple sectors including pharmaceuticals, electronics, and consumer goods. In the pharmaceutical industry, PVC pharmaceutical packaging adhesive is particularly important as it protects sensitive medications from contamination while providing tamper-evident features. Additionally, manufacturers in the electronics sector utilize this type of adhesive to secure components safely within their packages, ensuring they reach consumers intact.

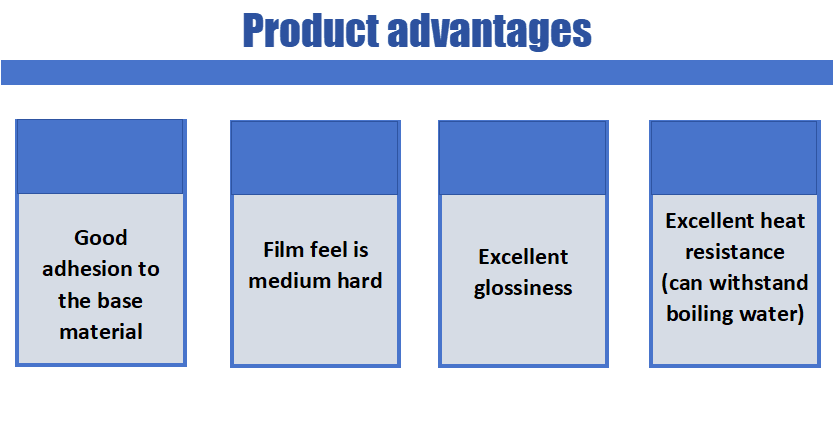

Advantages Over Traditional Adhesives

One major advantage of using PVC blister pack adhesives over traditional options is their superior bonding strength and resistance to moisture and chemicals. Unlike older adhesives that may degrade or lose effectiveness over time, modern PVC packaging adhesives maintain their integrity longer under various conditions. This reliability not only enhances consumer trust but also reduces waste by minimizing product damage during transit.

The Role of Water-Based Adhesives

In the world of packaging, water-based adhesives are making waves, particularly when it comes to PVC blister pack adhesive applications. These adhesives offer a multitude of benefits that make them an attractive choice for manufacturers and consumers alike. From enhanced safety profiles to improved performance, water-based adhesives are redefining the standards for durability and environmental responsibility in packaging.

Benefits of Using Water-Based Adhesives

One of the standout benefits of using water-based adhesives is their low toxicity, making them safer for both workers and end-users. Unlike solvent-based alternatives, these adhesives emit fewer volatile organic compounds (VOCs), which is a significant plus in today’s eco-conscious market. Additionally, water-based PVC packaging adhesive formulations often provide excellent adhesion properties on PVC film for blister packaging adhesive applications, ensuring that products remain securely sealed during transit.

Another key advantage lies in their versatility; they can be used across various substrates beyond just PVC film for blister packaging adhesive. This flexibility opens up opportunities for manufacturers to streamline production processes while maintaining high-quality standards. Furthermore, water-based adhesives are generally easier to clean up and handle compared to traditional solvents, resulting in a more efficient working environment.

Lastly, these adhesives contribute positively to sustainability efforts by reducing environmental impact without sacrificing quality or performance. As consumers increasingly demand eco-friendly products, utilizing water-based options can enhance brand reputation and customer loyalty in competitive markets like pharmaceuticals and consumer goods.

Chemix's Water-Based Resin Solution Explained

Chemix has taken the initiative to develop a cutting-edge water-based resin solution specifically designed for PVC blister pack adhesive applications. This innovative product not only meets but often exceeds industry standards for adhesion strength and durability on various substrates including PVC films used in pharmaceutical packaging. With Chemix's formulation, users can expect reliable performance that ensures product integrity throughout its lifecycle.

The unique composition of Chemix's resin allows it to bond effectively with PVC film for blister packaging adhesive while maintaining flexibility—an essential feature when dealing with dynamic packing environments where movement occurs frequently. Moreover, this solution is tailored to work seamlessly with existing manufacturing processes without requiring extensive adjustments or additional equipment investments.

By focusing on innovation and quality control within their product line-up, Chemix positions itself as a leader in the development of sustainable adhesive solutions that cater specifically to modern industry needs—making it an excellent choice for those seeking effective PVC packaging adhesive options.

Environmental Impact and Sustainability

When discussing the role of water-based adhesives like those from Chemix in the context of environmental impact and sustainability, it's hard not to get excited about their potential benefits! These formulations significantly reduce harmful emissions associated with traditional solvent-based adhesives—helping companies meet stricter regulatory requirements while minimizing their carbon footprint. As industries shift toward greener practices, adopting PVC pharmaceutical packaging adhesive solutions is not just beneficial but essential for long-term viability.

Moreover, many consumers today prioritize purchasing from brands that demonstrate a commitment to sustainability; using environmentally friendly materials can enhance marketability among eco-conscious customers who value responsible sourcing practices. By choosing water-based options over conventional methods, manufacturers can showcase their dedication towards preserving our planet while still delivering high-quality products that meet consumer demands.

In summary, incorporating sustainable practices through the use of advanced technologies like Chemix's water-based resin solution leads us toward a future where durable yet environmentally friendly options dominate the landscape—especially crucial within sectors such as healthcare where product safety is paramount!

Selecting the Right PVC Packaging Adhesive

Choosing the right PVC packaging adhesive is crucial for ensuring product integrity and consumer safety. With a variety of options available, it’s essential to consider factors like adhesion strength, compatibility with PVC film for blister packaging adhesive, and environmental impact. The decision can significantly affect production efficiency and product performance.

Criteria for Choosing the Best Adhesive

When selecting a PVC blister pack adhesive, several criteria come into play. First, you should assess the adhesive's bonding strength to ensure it can withstand various conditions during storage and transportation. Additionally, consider the curing time—faster curing adhesives can enhance production speed while maintaining quality.

Another important factor is compatibility with specific materials used in blister packs. For instance, if you are working with sensitive pharmaceutical products, opting for a PVC pharmaceutical packaging adhesive that meets regulatory standards is vital. Lastly, evaluate environmental considerations; water-based adhesives are often favored due to their lower VOC emissions and better sustainability profile.

Differences Between PVC Pharmaceutical Packaging Adhesives and Others

PVC pharmaceutical packaging adhesives differ significantly from general-purpose adhesives in terms of formulation and regulatory compliance. These specialized adhesives must meet stringent health standards since they come into contact with medications or medical devices. This means they often undergo rigorous testing to ensure they do not leach harmful substances into the packaged products.

Moreover, while standard PVC packaging adhesives may focus on cost-effectiveness and general performance metrics, pharmaceutical-grade options prioritize safety and efficacy above all else. They also tend to have enhanced barrier properties that protect sensitive contents from moisture or contamination—an essential feature when dealing with pharmaceuticals.

Understanding these differences helps manufacturers choose the right type of adhesive based on their specific needs while ensuring compliance with industry regulations.

Testing for Performance and Compliance

Testing is an integral part of selecting any PVC packaging adhesive; it ensures that the chosen product meets both performance expectations and regulatory standards. Various tests can be conducted on PVC blister pack adhesives to evaluate their adhesion properties under different conditions such as temperature fluctuations or exposure to moisture.

Compliance testing often involves checking against industry standards set by organizations like FDA or ISO for pharmaceutical applications specifically tailored for PVC pharmaceutical packaging adhesives. This guarantees that not only do these adhesives perform well but also uphold safety protocols necessary for consumer protection.

In addition to compliance testing, conducting field tests can provide valuable insights into how well an adhesive performs in real-world applications—allowing manufacturers to make informed decisions before finalizing their choice of PVC packing solutions.

Innovations in Adhesive Technology

The world of adhesive technology is experiencing a renaissance, particularly in the realm of PVC blister pack adhesives. As industries strive for efficiency and sustainability, innovations in durable adhesives are becoming increasingly pivotal. This evolution not only enhances packaging performance but also aligns with growing environmental concerns.

Emerging Trends in Durable Adhesives

One of the most exciting trends is the shift towards water-based adhesives, which offer a safer alternative to traditional solvent-based options. These water-based adhesives are gaining traction due to their lower environmental impact and reduced health risks for workers. Furthermore, advancements in formulations have led to enhanced bonding capabilities, making them ideal for various applications in PVC packaging adhesive.

Another trend is the increasing demand for multifunctional adhesives that can cater to diverse materials and conditions. This versatility allows manufacturers to streamline their processes by using a single adhesive type across different products, including PVC pharmaceutical packaging adhesive. Additionally, as consumer preferences evolve towards eco-friendly options, durable adhesives that meet these criteria are rapidly becoming industry standards.

How Technology Is Changing Blister Packaging

Technology is playing a transformative role in blister packaging by integrating smart features that enhance user experience and product protection. For instance, innovations like tamper-evident seals and moisture-resistant barriers are being incorporated into PVC film for blister packaging adhesive solutions. These advancements not only improve safety but also extend product shelf life—a win-win for manufacturers and consumers alike.

Moreover, automation technologies are revolutionizing how PVC packaging adhesive is applied during production processes. Automated systems ensure precise application rates and uniform coverage, reducing waste while improving overall efficiency. As technology continues to evolve, we can expect even more sophisticated methods that further enhance the performance of blister packs.

Future Prospects for PVC Films and Adhesives

Looking ahead, the future prospects for PVC films and adhesives appear bright as research continues into high-performance materials designed specifically for demanding applications. The development of next-generation PVC blister pack adhesives promises improved adhesion characteristics while maintaining flexibility and durability under various conditions. This means enhanced performance not just in pharmaceuticals but across multiple sectors relying on effective packaging solutions.

Additionally, sustainability will remain at the forefront of innovation efforts as manufacturers seek biodegradable or recyclable alternatives without compromising on quality or effectiveness. As regulatory pressures increase globally regarding environmental impact, we can anticipate significant breakthroughs that will redefine what it means to be an eco-conscious industry player using PVC film for blister packaging adhesive solutions effectively.

Best Practices for Application

When it comes to applying PVC blister pack adhesive, following best practices can make all the difference in achieving optimal results. Proper application techniques ensure that the adhesive bonds effectively with the PVC film for blister packaging adhesive, leading to durable and reliable packaging solutions. Let's delve into some key strategies for successful application.

Proper Techniques for Applying Adhesives

To start, surface preparation is crucial; clean and dry surfaces enhance adhesion quality significantly. When applying PVC packaging adhesive, consider using a uniform coating method such as roller or spray application to avoid uneven distribution that could compromise bond strength. Additionally, be mindful of environmental conditions—temperature and humidity can affect how well the water-based adhesive cures and adheres, so aim for controlled settings whenever possible.

Storage and Handling Tips for Optimal Performance

Storage conditions play a vital role in maintaining the effectiveness of your PVC pharmaceutical packaging adhesive. Keep adhesives sealed tightly in cool, dry environments to prevent degradation or contamination from moisture or air exposure. It's also wise to check expiration dates regularly; expired adhesives may not perform as expected, leading to potential issues down the line.

Troubleshooting Common Issues with PVC Adhesives

Even with proper techniques and storage habits, challenges can arise when working with PVC blister pack adhesives. If you notice insufficient bonding strength or peeling at seams, it might be time to reassess your surface preparation methods or check if you're using the right type of adhesive for your specific application needs. Additionally, if bubbles appear during curing, this could indicate improper application technique—ensure an even layer without trapping air pockets.

Conclusion

The world of packaging has seen a remarkable transformation, particularly with the rise of durable adhesive coatings like PVC blister pack adhesive. These adhesives not only provide superior bonding capabilities but also enhance the functionality and aesthetic appeal of products. The use of PVC film for blister packaging adhesive has become increasingly popular due to its versatility and reliability across various industries.

A Recap on Durable Adhesive Coatings

Durable adhesive coatings, particularly in the realm of PVC packaging adhesive, have revolutionized how products are packaged and presented to consumers. Their strength and resilience make them ideal for applications requiring longevity and protection, especially in the pharmaceutical sector where PVC pharmaceutical packaging adhesive is critical. As industries continue to innovate, the demand for robust and efficient adhesives will only grow stronger.

The Importance of Environmental Considerations

While durable adhesives like water-based adhesives offer impressive performance, it’s essential to consider their environmental impact as well. The shift towards sustainable practices means that manufacturers are increasingly looking for eco-friendly options that do not compromise on quality or efficiency. Emphasizing the use of water-based adhesives can help reduce harmful emissions and promote a healthier planet while maintaining product integrity.

Future of Blister Adhesives in Packaging

Looking ahead, the future of blister adhesives in packaging appears bright with continuous advancements in technology and materials science. Innovations such as enhanced formulations for PVC blister pack adhesive promise greater efficiency and sustainability without sacrificing performance. As consumer preferences evolve towards more environmentally friendly options, we can expect to see an increased focus on developing smarter solutions that cater to both market demands and ecological responsibilities.