Introduction

In the world of manufacturing and construction, the choice of adhesives can make or break a project. Industrial adhesives, particularly hot-melt adhesives, stand out for their versatility and reliability. With applications ranging from packaging to automotive assembly, understanding these bonding solutions is essential for any industry professional.

Why Choose Industrial Adhesives

Industrial adhesives are crucial in enhancing product performance and ensuring durability across various sectors. They provide strong bonds that can withstand environmental stressors while also being cost-effective and easy to apply. Choosing the right adhesive can streamline production processes and improve overall efficiency, making it a smart investment for businesses.

The Magic of Hot Melt Adhesives

Hot-melt adhesives are a favorite among manufacturers due to their quick-setting properties and ease of use. These thermoplastic materials melt when heated and solidify upon cooling, creating an incredibly strong bond almost instantly. The magic lies in their ability to adhere to diverse substrates without the need for complex curing processes, making them invaluable in fast-paced production environments.

The Diverse World of Sealants

Sealants play an equally important role in various industries by providing protection against moisture, air infiltration, and other environmental factors. From construction projects to automotive applications, sealants ensure that joints remain intact under pressure while offering flexibility where needed. Understanding the different types of sealants available allows professionals to select the best solution for their specific needs.

Understanding Hot Melt Adhesive

Hot melt adhesives are fascinating materials that have revolutionized the bonding industry. These thermoplastic adhesives are applied in a molten state and solidify upon cooling, creating strong bonds in a variety of applications. The versatility and efficiency of hot melt adhesive make it a go-to choice for manufacturers seeking reliable solutions.

What is Hot Melt Adhesive?

Hot melt adhesive is a type of thermoplastic adhesive that is solid at room temperature but becomes liquid when heated. This unique property allows it to be easily applied using various methods, such as extrusion or spraying, making it incredibly versatile for different applications. Once cooled, hot melt adhesives form strong bonds with substrates ranging from paper and cardboard to plastics and metals.

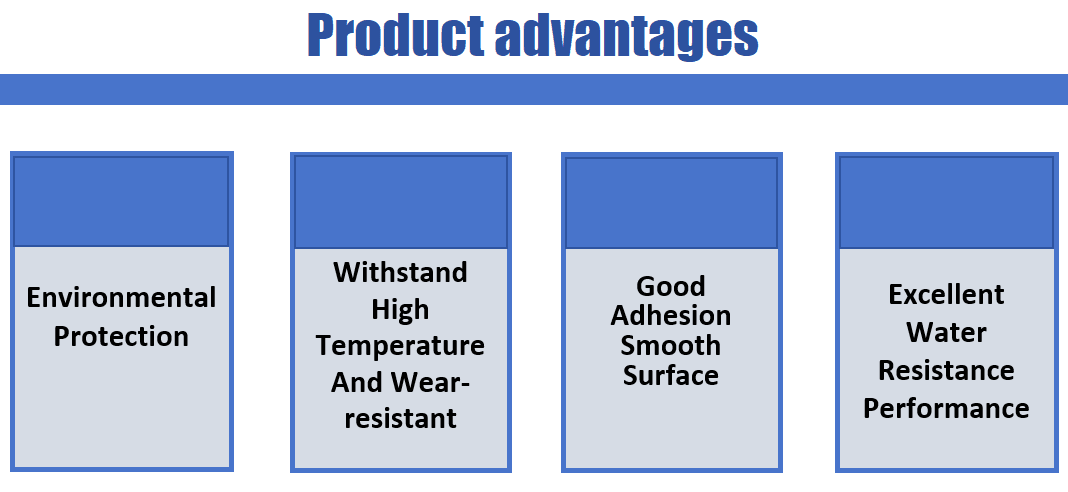

Advantages of Hot Melt Adhesives

One of the standout advantages of hot melt adhesives is their rapid setting time, which significantly increases production efficiency. Unlike other adhesive types that may require curing or drying time, hot melts bond quickly as they cool down, allowing manufacturers to streamline their processes. Additionally, these adhesives offer excellent adhesion properties and can withstand varying environmental conditions, making them suitable for diverse hot melt adhesive uses.

Another key benefit is their ability to bond dissimilar materials effectively. This adaptability makes hot melt adhesives a favorite among many industries looking for flexible solutions that can handle different substrates without compromising on strength or durability. Plus, they often come with lower application costs compared to other types of adhesives.

Common Industries Using Hot Melt Adhesives

Hot melt adhesives find their niche in numerous industries due to their versatility and reliability. The packaging sector heavily relies on these adhesives for product assembly and sealing tasks; think boxes, labels, and even food packaging! In the automotive industry, hot melts are used extensively for interior trim bonding and even electronic component assembly due to their strong performance under stress.

Moreover, construction companies utilize hot melt adhesive in various applications such as flooring installations and insulation bonding—proving that these adhesives are not just limited to light-duty tasks but can handle heavy lifting too! From manufacturing furniture to assembling toys, the diverse world of hot melt adhesive uses showcases its importance across multiple sectors.

Leading Hot Melt Adhesive Manufacturers

When it comes to hot-melt adhesives, a few manufacturers stand out as industry leaders, known for their innovation and reliability. These hot melt adhesive manufacturers have carved out their niches by providing high-quality solutions that cater to various industries. Understanding who they are can help you make informed decisions for your hot melt adhesive uses.

3M: Innovation and Reliability

3M is synonymous with innovation in the realm of hot-melt adhesives, consistently pushing the boundaries of what's possible. Their extensive range of products caters to diverse applications, from packaging to automotive assembly, ensuring that customers find the right solution for their needs. With a strong commitment to quality and reliability, 3M has earned its reputation as a go-to choice among hot melt adhesive manufacturers.

What sets 3M apart is not just their product range but also their focus on research and development. They continually invest in new technologies that enhance the performance of their hot melt adhesives, making them easier to apply and more effective in bonding various materials. Whether you're looking for quick-setting options or those that withstand extreme conditions, 3M has you covered.

Moreover, 3M’s customer support is top-notch—helping businesses navigate through the often complex world of adhesives with ease. Their expertise ensures that users get maximum performance from their chosen products while minimizing waste and downtime during application.

Henkel: A Trusted Name in Adhesives

Henkel has built a solid reputation as one of the most trusted names in adhesives globally, including in the domain of hot-melt adhesives. Known for producing high-quality products designed to meet rigorous industrial standards, Henkel's offerings span numerous sectors such as automotive and electronics manufacturing. Their commitment to sustainability also means they are continually innovating toward eco-friendlier solutions without sacrificing performance.

One standout feature of Henkel’s hot melt adhesive line is its versatility; these products can be used across various applications—from packaging to construction—making them indispensable tools in many industries. The company focuses on developing formulations that provide superior adhesion while reducing environmental impact—a win-win situation for both users and Mother Earth.

Additionally, Henkel offers comprehensive technical support and resources for businesses looking to optimize their processes with these adhesives. With Henkel by your side, you can trust you're getting not only quality but also expertise tailored specifically for your unique needs.

Bostik: Pioneers in Hot Melt Solutions

Bostik has made significant strides as pioneers in developing innovative hot-melt adhesive solutions tailored for specific applications across multiple industries. They focus heavily on creating specialized formulas designed to meet unique challenges—whether it’s ensuring strong bonds under stress or providing flexibility where needed most. This specialization makes Bostik a preferred choice among those who require targeted solutions within the realm of hot melt adhesive uses.

Their product lineup includes everything from standard formulations suitable for general use to advanced options engineered specifically for demanding environments like construction or automotive sectors. Bostik’s commitment to research ensures they stay ahead of trends while addressing evolving market needs effectively.

Furthermore, Bostik emphasizes sustainability within its manufacturing processes—ensuring that even while delivering exceptional performance through its hot-melt adhesives, environmental considerations remain at the forefront of production practices. This balance between innovation and responsibility positions Bostik favorably among other leading manufacturers in this competitive landscape.

Hot Melt Adhesive Uses

Hot melt adhesives are the unsung heroes of various industries, providing strong bonding solutions that are both efficient and versatile. These adhesives can be found in everyday applications, from packaging to automotive assembly, showcasing their flexibility and reliability. Understanding the diverse hot melt adhesive uses can help businesses make informed decisions about their bonding needs.

Packaging and Product Assembly

In the realm of packaging, hot melt adhesives play a crucial role in ensuring products are securely sealed and ready for shipment. From cardboard boxes to plastic containers, these adhesives provide quick bonding that enhances production speed without sacrificing quality. Hot Melt Adhesive manufacturers have tailored their products specifically for this industry, creating formulations that withstand various environmental conditions while maintaining adhesion strength.

Their ability to bond dissimilar materials makes them ideal for a wide range of products, including electronics and household items. With the increasing demand for sustainable packaging solutions, many companies are turning to eco-friendly hot melt adhesive options that align with their environmental goals.

Construction and Building Materials

The construction industry heavily relies on hot melt adhesives for a variety of applications, from flooring installations to insulation systems. These adhesives offer excellent bonding capabilities for building materials such as wood, concrete, and metal surfaces, ensuring structural integrity in any project. Hot Melt Adhesive manufacturers have developed specialized formulations that cater specifically to the unique demands of construction environments.

In addition to traditional uses in construction projects, hot melt adhesives are also utilized in prefabricated building components—allowing for faster assembly times without compromising on strength or durability. As green building practices gain popularity, more contractors are seeking out environmentally friendly options within the realm of hot melt adhesive uses. This shift not only reduces waste but also contributes positively to overall sustainability efforts within the industry.

Automotive and Transportation Applications

The automotive sector is another significant area where hot melt adhesives demonstrate their prowess by providing robust bonding solutions across various applications—from interior trim attachment to exterior body panels. These adhesives offer exceptional resistance against temperature fluctuations and vibrations encountered during vehicle operation, ensuring long-lasting performance under challenging conditions. Hot Melt Adhesive manufacturers understand these requirements well and produce tailored solutions specifically designed for automotive needs.

Moreover, as vehicles evolve with more advanced materials like composites and plastics becoming prevalent in modern designs, hot melt adhesives continue to adapt accordingly—maintaining their relevance within the transportation industry landscape. Their lightweight nature contributes positively toward overall vehicle efficiency while supporting stringent safety standards required by regulatory bodies worldwide. The versatility inherent in these adhesive solutions makes them indispensable when it comes time for innovation within automotive engineering processes.

Exploring Sealants for Every Need

Sealants are essential components in various industries, providing the necessary barrier against environmental factors and enhancing product durability. They come in many forms, each tailored to meet specific requirements and applications. Understanding the different types of sealants available can help you make informed decisions for your projects.

Types of Sealants Available

There are several types of sealants, each designed for unique applications and environments. Silicone sealants offer excellent flexibility and resistance to extreme temperatures, making them perfect for construction and automotive uses. On the other hand, polyurethane sealants provide strong adhesion and durability, often used in building materials where long-lasting performance is crucial.

Acrylic sealants are another popular choice due to their paintability and ease of application; they work well in indoor environments but may not withstand harsh weather conditions outdoors. For those looking for a quick-drying option, epoxy sealants can be incredibly effective, particularly in industrial settings where time is money. Lastly, there are hot melt adhesive variants that combine sealing properties with bonding capabilities, making them versatile solutions across various industries.

Key Applications for Sealants

Sealants play a vital role in numerous applications across sectors such as construction, automotive, and manufacturing. In construction, they are often used to fill gaps around windows and doors to prevent drafts and moisture intrusion; this enhances energy efficiency while protecting structural integrity. In the automotive industry, sealants help ensure that joints remain watertight while also providing sound dampening benefits.

Manufacturing processes frequently employ hot melt adhesives as sealant alternatives due to their quick curing times and strong bonds; these adhesives can streamline production by reducing assembly time significantly. Additionally, packaging industries utilize specialized sealants designed to create airtight seals that preserve product freshness during transportation. With so many hot melt adhesive uses available today, it’s clear that selecting the right type of sealant is crucial for ensuring optimal performance.

Choosing the Right Sealant for Your Project

Start by assessing the specific requirements of your application—this includes environmental conditions such as temperature fluctuations or exposure to moisture that could affect performance over time. Additionally, consider whether you need a flexible or rigid solution; this will guide you toward selecting between silicone or polyurethane options versus more solid alternatives like epoxy.

It’s also important to evaluate compatibility with materials involved in your project; using a hot melt adhesive alongside other materials may require specific formulations tailored for optimal adhesion without compromising integrity or safety standards. Finally, consult manufacturers' guidelines from leading hot melt adhesive manufacturers when selecting products—this ensures you have access to reliable options backed by research and development expertise within the industry.

Chemix's Water-Based Resin Solution

In the ever-evolving landscape of industrial adhesives, Chemix's water-based resin solution stands out as a modern alternative to traditional options like hot-melt adhesives. These resins offer a unique blend of performance and environmental friendliness, making them an attractive choice for manufacturers looking to reduce their ecological footprint. With versatility at their core, water-based resins are gaining traction across various sectors.

What is Water-Based Resin?

Water-based resin is a type of adhesive that utilizes water as its primary solvent, allowing for a more environmentally conscious bonding solution compared to solvent-based alternatives. Unlike hot-melt adhesives, which require heat to activate and bond materials, water-based resins cure through the evaporation of water content at room temperature or with slight heating. This makes them easier to handle and safer for both users and the environment while still providing robust adhesion.

Environmental Benefits of Water-Based Resin

One of the standout features of water-based resin is its minimal environmental impact compared to traditional hot-melt adhesives and other chemical-laden options. These resins emit fewer volatile organic compounds (VOCs), contributing to better indoor air quality and reduced pollution levels. Additionally, because they can be formulated with renewable resources, they align well with sustainability goals that many companies are striving for in today’s eco-conscious market.

Applications Across Various Industries

Water-based resins find applications in a multitude of industries, showcasing their versatility beyond just being an alternative to hot-melt adhesive solutions. They are commonly used in packaging materials where quick drying times are essential without compromising on strength or durability—an area where hot melt adhesive uses have traditionally dominated. From woodworking and textiles to automotive components and construction sealants, these resins provide reliable bonding solutions that meet diverse industrial needs.

Conclusion

In the ever-evolving world of industrial bonding, making the right choice in adhesives can feel like navigating a maze. With options ranging from hot-melt adhesives to various sealants, understanding your specific needs is crucial. By considering the characteristics and advantages of different products, you can ensure optimal performance and reliability in your projects.

Making the Right Choice in Adhesives

When it comes to choosing an adhesive, factors such as application type, material compatibility, and environmental conditions play a pivotal role. Hot-melt adhesives stand out for their versatility and quick bonding capabilities, making them a go-to option for many industries. Evaluating your project requirements against the offerings from leading hot melt adhesive manufacturers will help you make an informed decision that enhances efficiency and effectiveness.

The Future of Adhesives and Sealants

The landscape of adhesives and sealants is continuously changing, driven by innovation and sustainability demands. Hot melt adhesive uses are expanding as new formulations emerge that offer improved performance while reducing environmental impact. As industries seek greener alternatives, we can expect more advancements from hot melt adhesive manufacturers focused on creating eco-friendly solutions without compromising quality.

A Sustainable Approach to Industrial Bonding

Sustainability is no longer just a buzzword; it's becoming integral to industrial practices across sectors. Water-based resins are gaining traction alongside traditional hot-melt adhesives as companies strive for environmentally responsible solutions that maintain high performance standards. By embracing sustainable options in bonding technologies, businesses can reduce their ecological footprint while ensuring durability in applications ranging from packaging to construction.