Introduction

In the world of modern manufacturing and product design, the significance of hot melt coating cannot be overstated. This innovative technology combines efficiency with exceptional durability, making it a go-to solution for various applications. As industries strive for longevity and performance in their products, understanding heat seal technology becomes essential.

The Power of Hot Melt Coating

Hot melt coating is a game-changer in the realm of adhesives and coatings, offering unparalleled versatility across numerous sectors. With its ability to bond materials seamlessly, hot melt adhesive film has become increasingly popular due to its quick application and strong adhesion properties. By harnessing the power of heat seal bonding, manufacturers can enhance product integrity while reducing production times.

Why Durability Matters

In a competitive marketplace, durability is not just an added bonus; it's a necessity. Products that withstand wear and tear not only satisfy customer expectations but also reduce return rates and warranty claims for manufacturers. By utilizing hot melt coating techniques, companies can ensure that their items endure the test of time without compromising on quality or performance.

Understanding Heat Seal Technology

Heat seal technology is at the forefront of adhesive advancements, providing solutions that are both efficient and effective. But what is the process of hot melt coating? It involves applying heat to a thermoplastic adhesive until it melts and then bonding it to substrates upon cooling—a method that ensures a robust connection between materials. As we delve deeper into this topic, we will uncover how heat seal bonding enhances product lifespan across various industries.

What is Hot Melt Coating?

Hot melt coating is a fascinating technology that has transformed various industries by providing effective and durable solutions for bonding and sealing. This method involves applying a thermoplastic adhesive, which is heated until it melts, then applied to surfaces where it solidifies upon cooling. The result? A strong bond that enhances product durability and functionality.

Definition and Basics

At its core, hot melt coating refers to the application of a hot melt adhesive film onto substrates to create a protective or bonding layer. This process leverages heat seal technology, where the melted adhesive flows into the surface of the materials being bonded, creating an exceptionally strong connection once cooled. Essentially, it’s like giving your products a superpower—enhanced adhesion without compromising flexibility or strength.

Common Applications

Hot melt coating finds its way into numerous applications across diverse industries. From packaging solutions that require robust seals to automotive components needing reliable adhesion under stress, this technology is everywhere! It’s also widely used in textiles for lamination processes and in electronics for potting compounds, showcasing its versatility and adaptability in modern manufacturing.

Benefits Over Traditional Coatings

When comparing hot melt coatings to traditional coatings, several advantages stand out prominently. First off, hot melt adhesive films provide faster processing times since they don’t require curing or drying periods—just apply heat and let cool! Additionally, these coatings offer superior bonding strength and durability compared to conventional methods, making them ideal for products that endure wear and tear over time.

The Process of Hot Melt Coating

Hot melt coating is a fascinating process that transforms the way we apply coatings to various substrates, enhancing durability and performance. Understanding what is the process of hot melt coating allows manufacturers to leverage heat seal technology effectively. This section dives into the key steps, equipment, and quality control measures that ensure successful hot melt adhesive film applications.

Key Steps Explained

The process of hot melt coating begins with heating the adhesive until it reaches a molten state. This liquid adhesive is then applied to the substrate using various methods such as slot die, roll coating, or spray application. Once applied, the adhesive cools and solidifies quickly, forming a robust bond that benefits from heat seal bonding techniques for added durability.

Another crucial step involves selecting the right type of hot melt adhesive film based on specific application requirements. Factors like viscosity, melting point, and adhesion properties play significant roles in determining suitability for different materials. By understanding these variables, manufacturers can optimize their processes to achieve superior results.

Finally, post-application processes may include trimming excess material or applying additional layers for enhanced protection and performance. Each step in what is the process of hot coating contributes to creating a final product that meets rigorous industry standards while ensuring longevity through effective heat seal technology.

Equipment and Technology Used

To execute hot melt coating efficiently, specialized equipment is essential. Commonly used machinery includes extruders for melting adhesives and applicators designed for precise distribution on substrates. Advanced systems often incorporate temperature controls and sensors to maintain optimal conditions throughout the process.

Heat seal technology also plays a vital role in this equipment setup by facilitating strong bonds between materials during cooling phases. For instance, heated rollers may be used to enhance adhesion while ensuring uniform coverage across surfaces—crucial for achieving desired outcomes with hot melt coatings.

Moreover, innovations in automation have led to more streamlined operations within manufacturing environments where speed and efficiency are paramount. Utilizing cutting-edge technology allows companies to scale production while maintaining high-quality standards in their hot melt adhesive film applications.

Quality Control Measures

Quality control measures are indispensable when it comes to ensuring consistency and reliability in hot melt coating applications. Regular inspections throughout the production process help identify potential issues early on—whether it's an inconsistency in application thickness or improper adhesion due to temperature fluctuations.

Testing methodologies such as peel strength tests or shear testing provide valuable data regarding bond integrity after applying heat seal bonding techniques. By analyzing these results against established benchmarks, manufacturers can ascertain whether their products meet industry specifications before reaching consumers.

Furthermore, implementing continuous improvement strategies enables organizations to refine their processes over time—ultimately leading to better performance from their hot melt coatings while reducing waste and increasing efficiency overall. Staying vigilant about quality control ensures that every layer applied serves its purpose effectively without compromising durability or functionality.

Exploring Heat Seal Technology

Heat seal technology is a game changer in the world of bonding materials, particularly when it comes to enhancing product durability and performance. At its core, heat seal bonding involves applying heat and pressure to join two surfaces together, often utilizing hot melt adhesive film for optimal results. This method not only ensures a strong bond but also provides a seamless finish that can withstand various environmental challenges.

What is Heat Seal Bonding?

So, what exactly is heat seal bonding? It’s a process where heat is applied to activate adhesives—typically found in hot melt coatings—allowing materials to fuse together effectively. The beauty of this technique lies in its ability to create strong bonds without the need for additional solvents or complex curing processes, making it an efficient choice across industries.

This method can be utilized on various substrates such as plastics, films, and textiles, showcasing its versatility. By understanding the ins and outs of heat seal technology, manufacturers can leverage its benefits to improve their product offerings significantly. In essence, heat seal bonding stands out as an innovative solution that aligns perfectly with modern manufacturing demands.

Applications in Various Industries

Heat seal technology has carved out a niche in numerous sectors due to its flexibility and reliability. In the packaging industry, for example, it's commonly used for sealing bags and pouches that require airtight closures; this application often employs hot melt coating for added strength. Similarly, the textile industry utilizes heat seal bonding for creating durable seams in garments and upholstery items.

Beyond packaging and textiles, food processing also benefits from this technology by ensuring that products remain fresh through secure seals on containers. Moreover, automotive manufacturers use heat sealing techniques to bond components while maintaining aesthetic appeal without compromising structural integrity. Clearly, the applications of heat seal technology are extensive and continually expanding across diverse industries.

How it Enhances Product Lifespan

One of the standout benefits of using heat seal bonding is how it enhances product lifespan significantly. By employing hot melt adhesive film during production processes, manufacturers create bonds that resist wear and tear under various conditions—be it moisture exposure or temperature fluctuations. This durability translates into longer-lasting products that meet consumer expectations for quality and reliability.

Additionally, the seamless nature of these bonds means fewer points of failure compared to traditional adhesive methods; thus reducing maintenance costs over time while improving overall performance metrics. With advancements in hot melt coating technologies continually emerging, companies are better equipped than ever to develop products designed for longevity in competitive markets.

In summary, embracing heat seal technology not only elevates product quality but also extends their lifespan—a win-win situation for both manufacturers and consumers alike.

Advantages of Hot Melt Adhesive Film

Hot melt adhesive film is quickly becoming the go-to choice for many manufacturers due to its myriad advantages. From versatility in applications to its benefits in manufacturing processes, this innovative bonding solution is revolutionizing how we think about adhesion. Understanding these benefits can help businesses make informed decisions when choosing adhesives, especially when considering hot melt coating and heat seal technology.

Versatility in Applications

One of the standout features of hot melt adhesive film is its remarkable versatility across various industries. Whether it's packaging, textiles, or automotive applications, this adhesive can be utilized effectively in numerous scenarios. The adaptability of hot melt coating allows it to bond various substrates seamlessly, making it a favorite among manufacturers looking for reliable solutions.

In addition to its broad application spectrum, hot melt adhesive film is also compatible with different materials such as plastics, metals, and paper products. This compatibility ensures that businesses can use it across multiple production lines without needing extensive adjustments or new equipment. As a result, companies save time and resources while maintaining high-quality standards.

Moreover, the ease of application with heat seal technology enhances the overall efficiency of production processes. Manufacturers benefit from reduced cycle times and improved throughput as they leverage heat seal bonding methods to utilize hot melt coatings effectively. This versatility not only streamlines operations but also opens doors for innovative product designs that were previously thought impractical.

Benefits in Manufacturing

The integration of hot melt adhesive film into manufacturing processes brings several key benefits that can significantly enhance productivity and efficiency. First and foremost is the speed at which these adhesives bond—often within seconds—allowing for rapid assembly lines without compromising quality. This quick bonding time translates into shorter production cycles and increased output.

Additionally, the process of applying hot melt coating often requires less energy compared to traditional adhesives that may need curing or drying times. With heat seal technology facilitating quicker setups and fewer interruptions during production runs, manufacturers enjoy lower operational costs and improved profit margins over time. This efficiency makes a compelling case for adopting hot melting methods across various sectors.

Furthermore, using hot melt adhesive films contributes to waste reduction in manufacturing operations as they are typically applied with precision using automated systems. This minimizes excess material usage while maximizing bonding strength where it's needed most—a win-win scenario for both manufacturers and the environment alike!

Comparisons with Other Adhesives

When comparing hot melt adhesive film with other types of adhesives on the market today, several distinct advantages emerge clearly. Traditional solvent-based adhesives often involve lengthy curing times and require extensive safety measures due to volatile organic compounds (VOCs). In contrast, hot melting methods eliminate these concerns by providing an efficient solution without harmful emissions.

Another notable difference lies in durability; products utilizing heat seal bonding techniques with hot melt coatings tend to exhibit superior performance under stress compared to their counterparts using other adhesives like water-based options or epoxies. The resilience offered by these films ensures long-lasting bonds even under challenging conditions such as temperature fluctuations or exposure to moisture.

Lastly, cost-effectiveness plays a crucial role when evaluating different adhesion technologies; while some alternatives may have lower upfront costs per unit volume initially, their overall lifecycle expenses—including maintenance—can be substantially higher than those associated with using high-quality hot melt coatings over time! Businesses focusing on long-term viability will find that investing in advanced adhesive solutions like hot melt films pays off handsomely down the road.

Water-Based Resin Solutions by Chemix

In the ever-evolving landscape of adhesive technology, Chemix has introduced innovative water-based resin solutions that are making waves in the industry. These resins are designed to enhance hot melt coating processes while providing sustainable alternatives to traditional solvents. With a focus on versatility and performance, Chemix's water-based resins are setting new standards in heat seal technology.

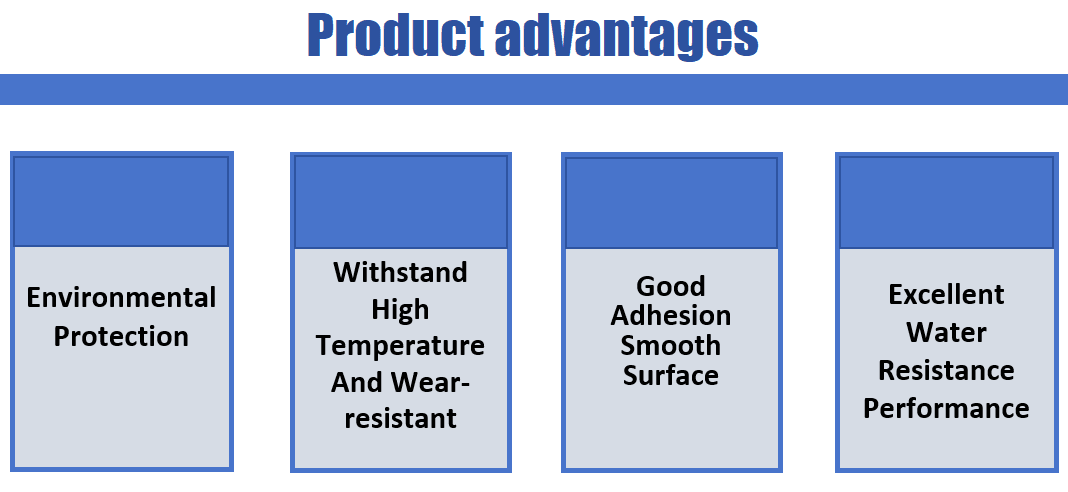

Features of Water-Based Resins

Water-based resins offer a range of features that make them ideal for various applications in hot melt coating. They provide excellent adhesion properties, ensuring strong bonds that can withstand environmental stressors. Additionally, these resins are formulated to dry quickly, facilitating efficient production processes without compromising quality.

One standout feature is their ability to work effectively across different substrates, which is crucial for industries relying on heat seal bonding techniques. The flexibility in formulation allows manufacturers to tailor the resin's properties to meet specific performance requirements. This adaptability makes water-based resins a go-to choice for many businesses looking to optimize their hot melt adhesive film applications.

Environmental Benefits

One of the most compelling reasons for choosing water-based resin solutions is their significant environmental benefits compared to solvent-based alternatives. These resins contain lower levels of volatile organic compounds (VOCs), contributing to improved air quality and reduced health risks for workers in manufacturing environments. By opting for water-based formulations, companies can align with sustainability goals and regulatory standards while still achieving superior performance.

Moreover, using water as a solvent reduces the carbon footprint associated with production and transportation processes. This eco-friendly approach resonates well with consumers who increasingly prioritize environmentally responsible products when making purchasing decisions. By implementing these solutions, businesses not only enhance their hot melt coating practices but also contribute positively to environmental stewardship.

Applications in Hot Melt Coating

The versatility of Chemix's water-based resins shines through in their wide-ranging applications within hot melt coating technologies. Industries such as packaging, textiles, and automotive benefit from these innovative adhesives due to their strong bonding capabilities and quick drying times. Whether used for lamination or surface coatings, these resins elevate product performance while ensuring durability through effective heat seal technology.

In packaging applications, for instance, they facilitate secure seals that maintain freshness and integrity while also being lightweight—a crucial factor for shipping efficiency. In textiles, they provide flexible yet robust bonds that withstand wear and tear without compromising comfort or appearance. As manufacturers explore what is the process of hot melt coating with these advanced materials, they discover new possibilities for enhancing product longevity through effective heat seal bonding techniques.

Conclusion

In the ever-evolving world of manufacturing and product design, the significance of hot melt coating cannot be overstated. By providing robust protection and enhancing product longevity, these coatings are essential for various applications across industries. As we embrace innovations in heat seal technology and hot melt adhesive film, we can expect to see remarkable improvements in durability and performance.

Boosting Product Longevity with Coatings

Hot melt coating plays a crucial role in extending the lifespan of products by offering superior resistance to wear, moisture, and environmental factors. This durability is particularly vital in industries where product reliability is paramount, such as packaging and automotive sectors. By utilizing advanced heat seal bonding techniques alongside hot melt coatings, manufacturers can ensure that their products withstand the test of time.

Innovations in Adhesive Technology

The landscape of adhesive technology is continually changing, with new formulations and processes emerging to meet modern demands. Hot melt adhesive film has taken center stage due to its versatility and efficiency in manufacturing processes. Innovations like water-based resin solutions are also paving the way for more environmentally friendly options without compromising on performance or quality.

Future Trends in Hot Melt Coating

Looking ahead, we can anticipate exciting developments within the realm of hot melt coating technology. The increasing focus on sustainability will likely drive research into eco-friendly alternatives that still deliver exceptional results—think bio-based adhesives or enhanced heat seal technology applications. Additionally, as industries seek answers to What is the process of hot melt coating? or What is the hot melting method?, educational initiatives will become essential for fostering understanding around these transformative technologies.