Introduction

In the world of manufacturing and DIY projects, understanding industrial contact adhesive is essential for achieving lasting results. This versatile adhesive glue is designed to create strong bonds between a variety of materials, making it a go-to choice for professionals and hobbyists alike. Whether you're working on furniture assembly or intricate crafts, knowing how to use contact adhesive effectively can elevate your work.

Understanding Industrial Contact Adhesive

Industrial contact adhesives are unique formulations that allow for immediate bonding upon contact, eliminating the need for lengthy curing times. These adhesives typically consist of a blend of rubber and resin, providing exceptional strength and flexibility once cured. With their ability to adhere to various substrates—such as wood, metal, and plastic—industrial adhesive solutions are indispensable in countless applications.

Importance of Proper Adhesive Techniques

Utilizing proper adhesive techniques is crucial when working with any type of adhesive glue, especially industrial spray adhesives. Applying too much or too little can significantly affect the bond strength and longevity of your project. By mastering the right methods for applying industrial contact adhesive, you can ensure that your creations withstand the test of time while maintaining their integrity.

Choosing the Right Adhesive for Your Needs

Selecting the appropriate adhesive can make all the difference in your project's success; not all adhesives are created equal! When considering options like industrial contact adhesives or other types such as epoxy or polyurethane glues, it's important to evaluate your specific needs carefully. Factors such as material compatibility, environmental conditions, and desired bond strength will guide you toward making an informed decision that suits your project perfectly.

The Science Behind Industrial Contact Adhesives

Understanding the science behind industrial contact adhesives is essential for anyone looking to harness their full potential. These specialized adhesive glues are designed to create robust bonds between various materials, making them indispensable in numerous industries. With the right application techniques and knowledge, you can achieve impressive results that stand the test of time.

What Are Industrial Contact Adhesives

Industrial contact adhesives are high-performance bonding agents formulated to adhere to a wide range of substrates, including wood, metal, plastic, and fabric. Unlike traditional adhesives that require clamping or curing time, contact adhesives bond instantly upon contact once they have been applied to both surfaces and allowed to dry momentarily. This unique property makes industrial spray adhesive particularly popular in fast-paced manufacturing environments where efficiency is key.

How They Work: Bonding Mechanism

The bonding mechanism of industrial contact adhesives relies on a combination of physical and chemical interactions between the adhesive glue and the surfaces being bonded. When two coated surfaces come into contact, the adhesive's solvent evaporates, allowing polymer chains to intertwine with the substrate at a molecular level. This creates a strong bond that can withstand shear forces and temperature variations, making these adhesives suitable for rigorous applications.

Benefits of Using Industrial Adhesives

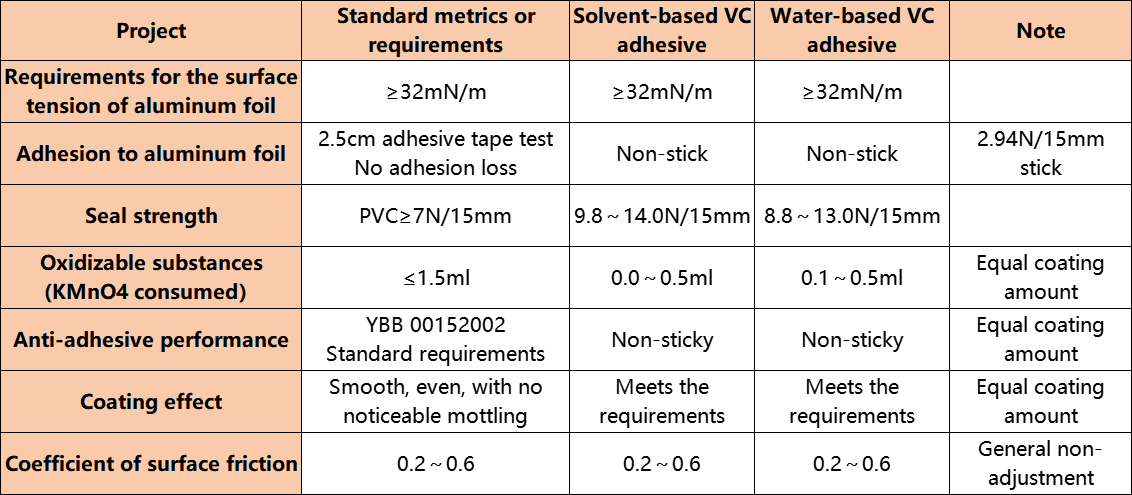

One of the primary benefits of using industrial adhesives is their versatility; they can be employed across various materials and industries without compromising performance. Additionally, industrial contact adhesives provide excellent resistance to heat and moisture compared to other types of bonding agents, ensuring longevity in challenging environments. Furthermore, advancements in adhesive technology have led to eco-friendly options like water-based formulations that maintain strength while reducing environmental impact.

Selecting the Right Type of Adhesive

Choosing the right adhesive is crucial for ensuring the success of your project. With a myriad of options available, understanding your specific needs can help streamline your decision-making process. From industrial contact adhesives to specialty adhesive glues, each type has its own unique properties and applications.

Evaluating Your Project Requirements

Before diving into the world of adhesives, it's essential to evaluate your project requirements thoroughly. Consider factors such as materials being bonded, the environmental conditions they'll face, and the desired strength of the bond. For instance, if you're working with porous materials like wood or fabric, an industrial spray adhesive may be more suitable than a traditional contact adhesive.

Additionally, think about how long you need the bond to last and whether it will be exposed to moisture or extreme temperatures. Some industrial adhesives are better suited for high-stress applications, while others excel in flexibility or resistance to chemicals. By taking these aspects into account, you'll be better positioned to select an adhesive that meets your specific needs.

Comparing Contact Adhesive to Other Types

When comparing contact adhesives to other types like epoxy or hot glue, it's important to understand their unique advantages and disadvantages. Contact adhesives offer instant bonding capabilities that can save time during application; however, they require precise alignment since repositioning after contact is often impossible. On the other hand, epoxy provides a stronger bond but typically requires longer curing times.

Moreover, industrial contact adhesives are ideal for large surface areas where quick adhesion is necessary—think flooring installations or laminating surfaces—while other types may be more suited for intricate projects needing detailed application techniques. Understanding these differences will empower you to make informed choices based on your project's demands rather than just convenience.

Exploring Chemix's Water-Based Resin Solution

In recent years, there has been a growing trend towards using water-based solutions in industrial applications due to their eco-friendliness and lower toxicity levels compared to traditional solvents used in adhesive glue formulations. Chemix's water-based resin solution stands out as an innovative alternative that retains strong bonding capabilities typical of industrial contact adhesives while minimizing harmful emissions.

This solution is particularly advantageous in environments where safety regulations are stringent or where workers' health is a concern—think textile manufacturing or construction sites where ventilation might be limited. With Chemix’s water-based resin solution at your disposal, you can achieve reliable performance without compromising on sustainability goals.

Essential Application Techniques

When it comes to using industrial contact adhesive, application techniques can make or break your project. A well-prepared surface and proper application are crucial for achieving a durable bond. Let’s dive into the essential steps to ensure your adhesive glue performs at its best.

Surface Preparation for Optimal Bonding

Before you even think about reaching for that industrial adhesive, surface preparation is key. Clean surfaces free of dust, grease, and moisture will ensure that the contact adhesive adheres properly without any unwanted surprises later on. For porous materials, consider sanding or scuffing the surface slightly to increase adhesion; this simple step can significantly enhance the bond strength of your industrial spray adhesive.

Applying Contact Adhesive Correctly

Applying contact adhesive may seem straightforward, but there’s an art to it! First off, make sure you apply an even coat on both surfaces; this ensures maximum coverage and a stronger bond when they come together. Remember to let each layer dry until it feels tacky—this is where the magic happens! Pressing the surfaces together at this stage creates a powerful bond that typical adhesive glue just can't match.

Tips for Achieving a Strong Hold

Achieving a strong hold with industrial adhesives isn’t just about slapping things together; it requires finesse! After applying your contact adhesive and letting it become tacky, align your materials carefully before pressing them down firmly—this ensures that air bubbles don’t form between surfaces. Lastly, if you're working in challenging environments like high humidity or extreme temperatures, be sure to choose an industrial spray adhesive specifically designed for those conditions.

Common Mistakes to Avoid

When working with industrial contact adhesive, it's easy to make some common blunders that can undermine your project. These mistakes can lead to weak bonds, wasted materials, and frustration. By being aware of these pitfalls, you can maximize the effectiveness of your adhesive glue and ensure a successful application.

Overusing Adhesive: Less Is More

One of the most frequent errors in using contact adhesive is overapplication. Many believe that slathering on more adhesive will create a stronger bond, but this couldn't be further from the truth. Industrial contact adhesives are designed for optimal performance with a specific amount; using too much can lead to oozing and poor adhesion as excess glue may not cure properly.

Applying just the right amount allows for better penetration into surfaces, ensuring a strong hold without wasting product. Remember that when it comes to industrial adhesive, less truly is more! So next time you're reaching for that can of industrial spray adhesive, think twice about how much you're applying.

Ignoring Drying Times

Another common mistake involves disregarding drying times when applying industrial adhesives. Each type of contact adhesive has its own recommended drying period before surfaces should be pressed together or subjected to stress. Rushing this process could result in a weak bond or even total failure of adhesion.

It's essential to follow the manufacturer's instructions regarding curing times and conditions; patience pays off! Allowing adequate time for drying not only enhances bond strength but also ensures safety during use—especially crucial in high-stakes environments like construction or manufacturing where reliability matters most.

Misjudging Environmental Conditions

Lastly, misjudging environmental conditions can wreak havoc on your bonding process with industrial adhesives. Factors like temperature and humidity significantly affect how well an adhesive glue performs; extreme conditions may compromise adhesion quality or prolong drying times unexpectedly.

For instance, applying an industrial spray adhesive in high humidity might lead to moisture interference with the curing process, resulting in subpar bonds. Always check environmental factors before starting your project—adjustments may be necessary to achieve optimal results!

Industry-Specific Applications

Industrial contact adhesives are not just a one-size-fits-all solution; they play a crucial role across various industries. From manufacturing to textiles and construction, the versatility of adhesive glue enables seamless bonding for diverse applications. Understanding how these adhesives function in specific sectors can help businesses enhance efficiency and product quality.

The Role of Adhesives in Manufacturing

In manufacturing, industrial adhesive solutions are essential for assembling components quickly and effectively. They provide strong bonds that can withstand mechanical stress, temperature fluctuations, and environmental factors—making them indispensable in production lines. Whether it’s automotive parts or electronic devices, using the right contact adhesive ensures durability and longevity of products while streamlining assembly processes.

Moreover, industrial contact adhesives facilitate the joining of dissimilar materials that traditional fasteners struggle with, such as metal to plastic or wood to glass. This flexibility allows manufacturers to innovate designs without compromising structural integrity. Ultimately, choosing the right industrial adhesive can lead to significant cost savings by reducing assembly time and minimizing material waste.

Using Industrial Spray Adhesive in Textiles

When it comes to textiles, industrial spray adhesive is a game changer for both manufacturers and DIY enthusiasts alike. This type of adhesive offers an even application that minimizes mess while providing a robust bond for fabrics used in upholstery, clothing production, or crafts. With its quick-drying properties, industrial spray adhesive allows for rapid project completion without sacrificing quality.

Textile manufacturers appreciate how contact adhesives maintain fabric flexibility while ensuring strong adhesion between layers or components like linings and interfacing materials. Additionally, many modern formulations are designed to be water-resistant or heat-resistant—ideal for items subjected to wear and tear over time. By incorporating the right adhesive glue into their processes, textile producers can enhance product durability while maintaining aesthetic appeal.

Innovations in Adhesive Glue for Construction

The construction industry has seen remarkable advancements with the development of specialized industrial adhesives that cater specifically to building materials like concrete, wood, and metal. Innovations such as polyurethane-based contact adhesives provide superior bonding strength while offering resistance against moisture and extreme temperatures—perfect for outdoor applications or areas prone to humidity. These cutting-edge solutions allow builders to achieve reliable results without relying on traditional mechanical fasteners.

Moreover, sustainable options are gaining traction within construction circles as more companies seek eco-friendly alternatives without compromising performance standards; water-based industrial contact adhesives fit this bill perfectly by reducing volatile organic compounds (VOCs). As technology evolves further into smart adhesives equipped with sensors that monitor bond integrity over time emerges on the market—a true testament to how far adhesive glue has come! Embracing these innovations not only enhances construction practices but also aligns with sustainability goals.

Conclusion

In wrapping up our exploration of industrial contact adhesives, it’s clear that understanding their unique properties and application techniques is crucial for achieving optimal results. From the science behind the bonding mechanism to the importance of selecting the right adhesive glue for your specific project, every detail matters. With proper techniques and knowledge, you can harness the full potential of industrial adhesives in various applications.

Key Takeaways on Industrial Adhesive Techniques

One of the most significant takeaways is that less can often be more; overusing contact adhesive can lead to messy results and weak bonds. Proper surface preparation plays a vital role in ensuring a strong hold, so don’t skip this essential step! Additionally, always pay attention to drying times and environmental conditions when applying your industrial spray adhesive to guarantee lasting results.

Future Trends in Adhesive Technology

The future of adhesive technology is bright, with innovations aimed at improving performance and sustainability on the horizon. Advancements in formulations are leading to more effective industrial contact adhesives that cater to diverse materials while minimizing environmental impact. Expect to see an increase in smart adhesives that adapt their properties based on conditions, making them even more versatile for industrial applications.

Embracing Sustainability with Water-Based Solutions

As industries increasingly prioritize eco-friendly practices, water-based solutions are becoming a popular choice among manufacturers looking for sustainable options without sacrificing performance. These innovative adhesives provide robust bonding capabilities while reducing harmful emissions associated with traditional solvent-based products. By embracing these advancements in adhesive glue technology, businesses can contribute positively to environmental conservation while maintaining high standards of quality.