Introduction

In the fast-paced world of pharmaceuticals, coating solutions play a pivotal role in ensuring product integrity and safety. From Pharmaceutical PVC coating and laminating solutions to innovative barrier technologies, these advancements are crucial for maintaining the quality of medications throughout their lifecycle. As we delve into this topic, we will explore not only the significance of these coatings but also how they contribute to enhanced packaging strategies.

The Role of Pharmaceutical PVC Coating

Pharmaceutical PVC coating plays a pivotal role in enhancing the integrity and performance of packaging solutions in the healthcare sector. With its unique properties, this type of coating offers significant advantages that cater specifically to the stringent requirements of pharmaceutical products. As the demand for effective and reliable packaging continues to rise, understanding the benefits and applications of PVC coated laminates becomes essential for manufacturers and consumers alike.

Benefits of PVC Coating in Packaging

The benefits of pharmaceutical PVC coating are manifold, making it a popular choice in medical packaging applications. Firstly, PVC coatings provide excellent moisture resistance, which is crucial for preserving sensitive pharmaceuticals from environmental factors that could compromise their efficacy. Additionally, these coatings offer superior clarity and printability, allowing for eye-catching branding while ensuring that vital product information remains visible.

Moreover, pharmaceutical PVC coating contributes to cost-effectiveness by reducing material waste during production processes. Its robust nature also enhances durability against physical stressors like tearing or puncturing—ensuring that the packaged products maintain their quality throughout their shelf life. Overall, when considering various options like Premium Barrier Coatings or PVDC Coated Laminates, it's clear that PVC stands out as an efficient solution for many pharmaceutical packaging needs.

Applications of PVC Coated Laminates

PVC coated laminates find diverse applications across the pharmaceutical industry due to their versatile nature and protective qualities. These laminates are commonly used in blister packs, sachets, and pouches designed to store tablets or capsules safely while providing an effective barrier against moisture and contaminants. Furthermore, they are ideal for creating labels and inserts that require high-quality print finishes without sacrificing protection.

In addition to traditional applications, innovative uses are emerging as manufacturers seek new ways to enhance product safety through advanced packaging solutions. For instance, integrating pharmaceutical PVC coating with other materials can lead to hybrid solutions that combine benefits from both worlds—like improved barrier properties found in Premium Barrier Coatings alongside the resilience offered by PVC films. This adaptability positions PVC coated laminates as a cornerstone technology within modern pharmaceutical packaging strategies.

Key Players in PVC Coating Technology

The landscape of pharmaceutical PVC coating is populated by several key players who drive innovation within this sector. Companies such as Amcor and Constantia Flexibles have established themselves as leaders by offering cutting-edge formulations tailored specifically for medical applications—balancing performance with regulatory compliance effectively. Their advancements often integrate insights gained from collaborations with research institutions focused on developing next-generation materials.

Another noteworthy contributor is Sealed Air Corporation which specializes in protective packaging solutions; their expertise extends into producing high-quality laminated films incorporating pharmaceutical PVC coatings designed for maximum efficiency and durability under various conditions. By staying ahead with technological advancements such as automation or eco-friendly alternatives like water-based adhesives—these companies continue shaping how we perceive Pharmaceutical Packaging Films today.

As we move forward into an era where sustainability meets innovation within medical packaging realms—understanding these key players' contributions will be essential for stakeholders looking to implement effective solutions tailored specifically around their needs while maintaining compliance with industry standards.

Exploring Premium Barrier Coatings

In the ever-evolving landscape of pharmaceutical packaging, Premium Barrier Coatings stand out as a game-changer. These coatings are designed to provide superior protection against moisture, oxygen, and other environmental factors that can compromise product integrity. By integrating advanced materials and technologies, these coatings ensure that pharmaceutical products remain safe and effective throughout their shelf life.

What are Premium Barrier Coatings?

Premium Barrier Coatings are specialized formulations applied to packaging materials to enhance their protective qualities. Unlike standard coatings, these premium solutions offer an exceptional barrier against gases and vapors, making them ideal for sensitive pharmaceutical products. Their unique composition often incorporates polymers that create a dense matrix, ensuring that the contents remain uncontaminated by external elements.

These coatings are especially crucial in the world of Pharmaceutical PVC coating and laminating solutions, where maintaining product stability is paramount. The ability to customize these coatings further enhances their application across various types of Pharmaceutical Packaging Films. As a result, manufacturers can tailor the barrier properties to meet specific requirements for different medications or formulations.

Enhancing Shelf Life with Barrier Properties

One of the most significant advantages of using Premium Barrier Coatings is their ability to extend shelf life significantly. By minimizing permeation rates of oxygen and moisture, these coatings help preserve the efficacy of active ingredients in pharmaceuticals over time. This not only benefits manufacturers by reducing waste but also ensures that patients receive medications with optimal potency when they need them.

Moreover, enhanced barrier properties contribute to better overall product quality during storage and transportation—essential factors in today's global supply chain for pharmaceuticals. When combined with Pharmaceutical PVC coating and laminating solutions, these barriers create a formidable defense against environmental challenges faced by sensitive drugs. The result? A more reliable product reaching consumers in peak condition.

Leading Brands in Barrier Coating Innovations

In this competitive market landscape, several leading brands have risen to prominence due to their innovative approaches towards developing Premium Barrier Coatings. Companies like Amcor and Sealed Air have pioneered new technologies that enhance barrier performance while maintaining sustainability—a growing concern within the industry today. Their commitment not only focuses on protecting pharmaceutical products but also on reducing environmental impact through recyclable materials.

Other notable players include Dow Chemical Company and BASF—both recognized for their cutting-edge research into advanced polymer systems used in PVDC coated laminates as well as other barrier solutions tailored specifically for pharmaceuticals. As demand continues to grow for high-performance packaging options, these brands are setting benchmarks through continuous innovation in both performance attributes and sustainable practices within Pharmaceutical Packaging Films.

Pharmaceutical Packaging Films: An Overview

When it comes to pharmaceutical packaging, the choice of films is crucial for ensuring product integrity and safety. Various types of films are employed, each designed to meet specific requirements in terms of protection, barrier properties, and compliance with industry standards. From flexible films to rigid structures, understanding these options is essential for effective pharmaceutical PVC coating and laminating solutions.

Types of Films Used in Pharmaceutical Packaging

Pharmaceutical packaging films can be broadly categorized into several types, each serving unique purposes. Common materials include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and polyvinylidene chloride (PVDC) coated laminates. These films are chosen based on their barrier properties, moisture resistance, and ability to protect sensitive medications from environmental factors.

Flexible films are often used for blisters and pouches due to their lightweight nature and adaptability. Rigid films may be utilized in containers that require enhanced durability against physical stressors. The selection of the right film type directly influences the effectiveness of premium barrier coatings applied during the packaging process.

Advantages of Using Pharmaceutical Packaging Films

The advantages of using specialized pharmaceutical packaging films are manifold, particularly when it comes to protecting sensitive products like medicines or vaccines. One primary benefit is their exceptional barrier properties which help maintain product efficacy by preventing moisture and oxygen ingress—critical factors that can degrade pharmaceuticals over time. Furthermore, these films can be engineered for compatibility with various pharmaceutical PVC coating and laminating solutions.

Another key advantage lies in compliance; many packaging films meet stringent regulatory requirements set by health authorities worldwide, ensuring safety for consumers. Additionally, the versatility offered by these films allows manufacturers to tailor their packaging solutions according to specific needs—be it child-resistant features or tamper-evident designs. This level of customization enhances both functionality and user experience.

Noteworthy Manufacturers of Packaging Films

Several manufacturers are leading the way in producing high-quality pharmaceutical packaging films that integrate seamlessly with premium barrier coatings like PVDC coated laminates. Companies such as Amcor, Sealed Air Corporation, and Berry Global have established themselves as key players in this sector by continuously innovating their film technologies while adhering to strict regulatory standards.

These manufacturers not only focus on enhancing film performance but also prioritize sustainability through eco-friendly practices in production processes—an increasingly important factor in today’s market landscape. Their commitment ensures that clients receive reliable products that align with modern environmental expectations while still offering superior protection for pharmaceuticals packaged within them.

In summary, understanding the various types of pharmaceutical packaging films available is vital for any entity involved in drug manufacturing or distribution. By leveraging advancements in film technology alongside effective premium barrier coatings such as PVDC coated laminates or innovative pharmaceutical PVC coating and laminating solutions, companies can significantly enhance product longevity while ensuring consumer safety.

Chemix's Water-based VC Composite Adhesive

In the realm of pharmaceutical packaging, Chemix's water-based VC composite adhesive stands out as a game-changer. This innovative adhesive not only meets stringent industry standards but also prioritizes environmental sustainability, making it a preferred choice among manufacturers. With the increasing demand for eco-friendly solutions in pharmaceutical PVC coating and laminating solutions, Chemix is leading the charge toward greener practices.

Environmental Benefits of Water-based Adhesive

One of the most compelling advantages of Chemix's water-based VC composite adhesive is its minimal environmental impact. Unlike solvent-based adhesives that release harmful volatile organic compounds (VOCs), this water-based alternative significantly reduces emissions during production and application. By opting for this eco-conscious solution, companies can align their operations with global sustainability goals while ensuring compliance with regulations surrounding Premium Barrier Coatings.

Moreover, using water as a primary solvent means that waste management becomes simpler and more efficient. The reduction in hazardous waste not only benefits the environment but also enhances worker safety in manufacturing facilities. As industries increasingly prioritize green initiatives, Chemix’s commitment to sustainability through their water-based adhesive positions them favorably within the competitive landscape of pharmaceutical packaging films.

Performance Features of VC Composite Adhesive

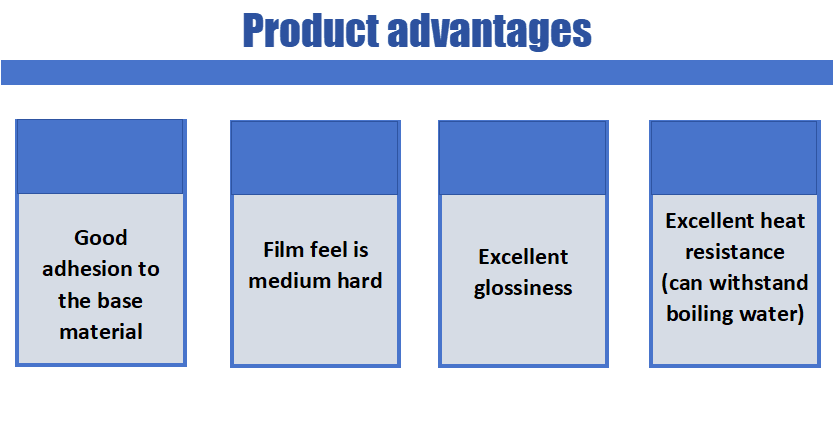

When it comes to performance, Chemix’s VC composite adhesive does not disappoint; it offers exceptional bonding strength essential for durable pharmaceutical packaging applications. The formulation ensures excellent adhesion across various substrates commonly used in pharmaceutical PVC coating and laminating solutions, including films and foils designed for barrier protection. This versatility makes it an ideal choice for manufacturers looking to enhance product integrity while maintaining compliance with industry standards.

Additionally, the adhesive exhibits remarkable resistance to moisture and temperature fluctuations—key factors that can compromise product quality over time. By enhancing shelf life through robust sealing properties, this adhesive supports the effectiveness of Premium Barrier Coatings by minimizing exposure to external elements that could degrade sensitive medications or medical devices. Thus, users can trust that their products remain safe and effective throughout their intended shelf life.

Industry Applications and Success Stories

Chemix's water-based VC composite adhesive has found success across various sectors within the pharmaceutical industry due to its adaptability and reliable performance characteristics. Pharmaceutical packaging films employing this technology have been widely adopted by leading manufacturers who prioritize both efficiency and sustainability in their processes. Notable case studies highlight how companies have successfully integrated these adhesives into their production lines while achieving significant reductions in waste generation.

For instance, a major player in medical device packaging reported enhanced operational efficiency after switching to Chemix’s adhesive—cutting down on drying times while improving bond strength in PVDC coated laminates used for sensitive products like syringes and IV bags. Similarly, another manufacturer noted how utilizing this eco-friendly solution contributed positively to their corporate social responsibility goals without compromising on quality or performance metrics associated with traditional adhesives used in pharmaceutical PVC coating applications.

As innovation continues to shape the future of medical packaging solutions, Chemix’s commitment to developing sustainable options demonstrates how environmental responsibility can coexist harmoniously with high-performance requirements demanded by today’s market.

Innovations in PVDC Coated Laminates

In the ever-evolving landscape of pharmaceutical packaging, PVDC (Polyvinylidene Chloride) coated laminates are emerging as a game-changer. These innovative materials combine excellent barrier properties with versatility, making them a popular choice for various applications in the pharmaceutical industry. As manufacturers seek effective solutions to enhance product integrity and longevity, PVDC coated laminates are stepping into the spotlight.

Understanding PVDC Coated Laminates

PVDC coated laminates are composite materials that feature a layer of PVDC applied to substrates such as paper, foil, or plastic films. This coating provides an exceptional barrier against moisture, oxygen, and other environmental factors that can compromise product quality. By understanding the science behind these coatings, companies can leverage their benefits for superior pharmaceutical packaging solutions.

The unique properties of PVDC make it particularly suitable for sensitive pharmaceutical products that require protection from external elements. Its ability to maintain product efficacy while extending shelf life is crucial in today’s market where consumer safety is paramount. Furthermore, PVDC's compatibility with various pharmaceutical PVC coating and laminating solutions allows for seamless integration into existing manufacturing processes.

Benefits of Using PVDC in Packaging

The advantages of using PVDC in packaging extend beyond mere protection; they include enhanced shelf life and improved product stability. With its superior barrier properties, products packaged in PVDC coated laminates remain fresher for longer periods compared to those using traditional materials. This translates to reduced waste and increased consumer satisfaction—an essential aspect when considering Premium Barrier Coatings.

Moreover, the application of PVDC can significantly lower production costs by minimizing spoilage during transit and storage. Pharmaceutical companies benefit from reduced returns and increased trust from consumers who rely on the integrity of their medications. In an industry where precision matters most, utilizing advanced materials like PVDC coated laminates is not just smart; it's essential.

Major Companies and Their PVDC Offerings

Several key players have made significant strides in developing innovative PVDC coated laminate technologies tailored for the pharmaceutical sector. Companies like Amcor and Constantia Flexibles have established themselves as leaders by providing high-quality Pharmaceutical Packaging Films that incorporate cutting-edge barrier technologies. Their commitment to research and development ensures that they stay ahead of industry trends while addressing evolving customer needs.

Additionally, firms such as Sealed Air Corporation have introduced specialized solutions featuring enhanced performance characteristics through advanced lamination techniques involving PVC coatings alongside their premium offerings. These innovations reflect a broader trend towards sustainable practices within the industry while maintaining compliance with stringent regulatory standards.

As demand grows for effective packaging solutions across various therapeutic areas—from over-the-counter medications to complex biologics—these companies continue to push boundaries with their offerings in the realm of PVDC coated laminates.

Conclusion

In the ever-evolving world of pharmaceutical packaging, staying ahead of trends is crucial for ensuring product integrity and safety. The future of pharmaceutical coatings looks promising, with innovations in Pharmaceutical PVC coating and laminating solutions leading the charge. As manufacturers continue to prioritize sustainability and efficiency, we can expect advancements in Premium Barrier Coatings and other protective technologies that enhance shelf life and product performance.

Future Trends in Pharmaceutical Coatings

The landscape of pharmaceutical coatings is shifting towards more sustainable options that do not compromise on quality or effectiveness. With a growing emphasis on eco-friendliness, water-based adhesives and biodegradable materials are gaining traction, complementing traditional Pharmaceutical PVC coating methods. Furthermore, the rise of smart packaging technologies will likely integrate with existing solutions like PVDC coated laminates to provide real-time monitoring of product conditions.

The Impact of Technology on Medical Packaging

Technology's influence on medical packaging cannot be overstated; it has revolutionized how products are preserved and delivered to consumers. Advanced manufacturing techniques are enhancing the performance of Pharmaceutical Packaging Films, making them more resilient against environmental factors while maintaining compliance with regulatory standards. Innovations such as active packaging systems will further bolster the effectiveness of Premium Barrier Coatings by incorporating features that actively respond to changes in humidity or temperature.

Choosing the Right Solutions for Your Needs

Selecting the right packaging solution requires a careful assessment of your specific needs and objectives within the pharmaceutical sector. Whether you are leaning towards Pharmaceutical PVC coating for its durability or exploring PVDC coated laminates for their superior barrier properties, understanding each option's strengths is key to making an informed decision. Ultimately, aligning your choice with industry trends and technological advancements will ensure your products remain competitive while meeting consumer expectations.