Introduction

Blister clamshell packaging is a popular choice for many products, but it’s not without its challenges. The common pitfalls in blister packaging often stem from poor adhesive choices, which can lead to product damage or customer dissatisfaction. Selecting the right adhesive is crucial for ensuring that your packaging performs as expected and meets industry standards.

Common Pitfalls in Blister Packaging

One of the most frequent mistakes made in blister clamshell packaging is the improper selection of adhesives, which can compromise both safety and functionality. Many manufacturers overlook essential factors such as compatibility with materials and environmental conditions, leading to failures in seal integrity. Additionally, failing to account for the specific requirements of medical disposable device adhesives can result in costly recalls and reputational damage.

Importance of Choosing the Right Adhesive

Choosing the best adhesive glue is vital not only for operational efficiency but also for compliance with regulations, especially when dealing with medical grade adhesives. The right adhesive ensures that products remain securely sealed while also being easy to open for consumers—a balancing act that requires careful consideration of various adhesive types. Moreover, using high-quality industrial adhesive supplier options helps guarantee reliability and consistency across production runs.

Eco-Friendly Options for Packaging

As consumers become increasingly environmentally conscious, eco-friendly adhesives are gaining traction in blister clamshell packaging applications. These green alternatives often offer comparable performance to traditional options while minimizing environmental impact—a win-win situation for both manufacturers and customers alike. By embracing eco-friendly adhesive solutions, businesses can not only enhance their brand image but also contribute positively to sustainability efforts within their industries.

Understanding Blister Clamshell Packaging Adhesives

When it comes to blister clamshell packaging adhesives, understanding the different types available is crucial for selecting the best adhesive glue for your specific needs. The market is flooded with options ranging from traditional solvent-based adhesives to innovative eco-friendly adhesive solutions. Each type has its unique properties and applications, making it vital to choose wisely based on product requirements and environmental considerations.

Types of Adhesives for Packaging

Blister clamshell packaging adhesives can be broadly categorized into several types: hot melt adhesives, water-based adhesives, and solvent-based adhesives. Hot melt adhesives are known for their quick setting times and strong bonding capabilities but may not always be the most eco-friendly option. On the other hand, water-based and composite adhesive formulations are gaining popularity due to their lower environmental impact while still providing robust performance in various applications.

Choosing the right adhesive often hinges on specific use cases; for example, medical grade adhesives are essential in applications involving medical disposable devices where safety and compliance are non-negotiable. Eco-friendly adhesive options continue to rise as consumers demand more sustainable practices from manufacturers. Ultimately, understanding these types will help you navigate through your choices effectively.

Key Characteristics of Medical Grade Adhesives

Medical grade adhesives possess several key characteristics that set them apart from standard industrial options. They must meet stringent regulatory requirements ensuring they are safe for direct contact with skin or sensitive materials used in medical disposable devices. This includes biocompatibility testing to avoid adverse reactions when used in healthcare settings.

Furthermore, medical grade adhesives often demonstrate superior performance under various conditions such as temperature fluctuations and humidity levels—factors that can significantly affect adhesion quality in blister clamshell packaging applications. Their ability to maintain integrity over time while adhering securely makes them a top choice when safety cannot be compromised.

Additionally, these specialized adhesives typically have low toxicity levels and minimal odor, which are essential characteristics for any product intended for use within healthcare environments or OTC packaging scenarios.

Applications of Industrial Adhesives

Industrial adhesive suppliers offer a range of products tailored specifically for blister clamshell packaging needs across various sectors including pharmaceuticals, electronics, and consumer goods. From securing delicate electronic components to ensuring tamper-evident seals on medication packages, industrial-grade adhesives play a pivotal role in maintaining product integrity during transport and storage.

In particular, composite adhesive formulations have become increasingly popular due to their versatility across different materials like plastics, metals, and even paperboard used in blister packaging designs. These industrial-grade solutions not only enhance durability but also contribute toward creating more sustainable packaging options by reducing waste through effective bonding techniques.

Moreover, with advancements in technology leading to improved formulations of eco-friendly adhesive solutions, businesses now have access to high-performance alternatives that align with sustainability goals without sacrificing effectiveness—making them ideal choices within modern manufacturing processes.

Choosing the Best Adhesive Glue for Your Needs

Selecting the right adhesive glue for your blister clamshell packaging can feel like navigating a maze. With so many options available, it’s essential to weigh the pros and cons of eco-friendly adhesives versus traditional choices. Each type of adhesive has its unique strengths, making it crucial to identify which aligns best with your specific requirements.

Comparing Eco-Friendly Adhesives vs. Traditional

Eco-friendly adhesives are gaining traction in various industries, particularly in blister clamshell packaging, due to their sustainable properties. Unlike traditional adhesives that may contain harmful solvents, eco-friendly options often use water-based formulas that minimize environmental impact while still providing strong bonding capabilities. However, some traditional adhesives may offer higher performance metrics in certain applications, making it vital to assess your priorities—whether sustainability or strength takes precedence.

When comparing these options, consider factors like curing time and bonding strength, as well as regulatory compliance for medical grade adhesives if you're working with medical disposable devices. Eco-friendly adhesives can be just as effective when properly formulated; they often perform admirably under various conditions without compromising safety standards. Ultimately, choosing between eco-friendly and traditional options boils down to balancing performance needs with environmental responsibilities.

Benefits of Using Composite Adhesives

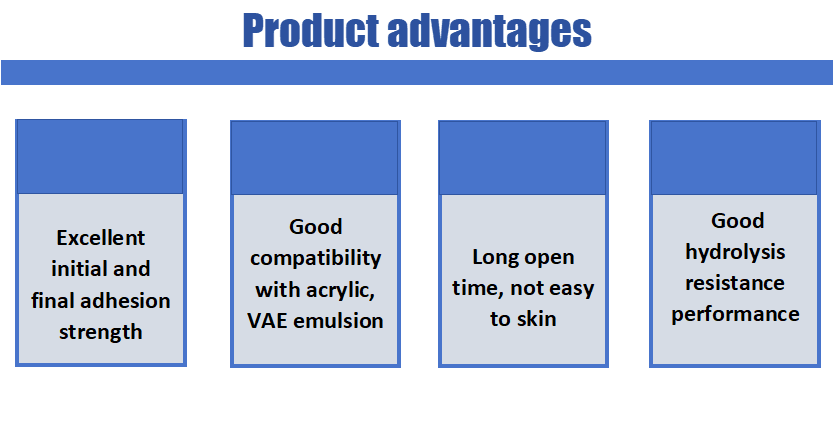

Composite adhesives are a game-changer in the world of adhesive technology and offer numerous advantages over single-component solutions. These versatile formulations combine different types of resins and hardeners to create a robust bond suitable for demanding applications like blister clamshell packaging and medical disposable devices. Their ability to adapt to various substrates makes them an excellent choice for those looking for the best adhesive glue that provides flexibility without sacrificing strength.

One significant benefit of composite adhesives is their enhanced durability against environmental factors such as moisture and temperature fluctuations—an essential consideration when selecting industrial adhesive suppliers who understand your specific needs. Additionally, composite formulations can often be tailored to meet unique project requirements, offering customizable solutions that traditional adhesives simply cannot match. This adaptability not only simplifies the selection process but also ensures optimal performance across diverse applications.

Factors to Consider When Selecting Adhesives

When it comes time to select an adhesive for your packaging needs, several critical factors should guide your decision-making process beyond just brand preference or price point. First and foremost is compatibility with materials; ensure that the chosen adhesive works well with both blister clamshell packaging materials and any product you plan on sealing within them. Additionally, consider whether you need medical grade adhesives if you're dealing with sensitive products or applications requiring stringent safety standards.

Another key factor is application method; some adhesives require specialized equipment or techniques while others can be applied easily by hand or standard machinery—this could influence whether you work directly with an industrial adhesive supplier or opt for off-the-shelf (OTC) packaging solutions instead. Don't forget about cure times! Selecting an adhesive that cures quickly could significantly enhance production efficiency but may come at the cost of bond strength if not chosen wisely.

Lastly, always account for long-term performance expectations—will this adhesive hold up under stress? By carefully weighing these considerations against your project goals and constraints, you’ll be better equipped to choose an effective solution tailored specifically for your needs.

Common Mistakes in Adhesive Application

When it comes to using blister clamshell packaging adhesives, the application process can often be riddled with pitfalls. Many manufacturers underestimate the importance of proper techniques and materials, leading to subpar results that can compromise product integrity and customer satisfaction. Avoiding these common mistakes is crucial for achieving optimal performance from your chosen adhesive, whether it's medical grade adhesives or eco-friendly options.

Overlooking Surface Preparation

One of the most significant blunders in adhesive application is neglecting surface preparation. Properly cleaning and preparing surfaces ensures that the best adhesive glue adheres effectively, resulting in a stronger bond. Without this crucial step, contaminants like dust or oil can interfere with adhesion, especially when using composite adhesives designed for specific applications such as medical disposable device adhesives.

Ignoring Temperature and Humidity Factors

Temperature and humidity play pivotal roles in the performance of blister clamshell packaging adhesives but are often overlooked during application. Extreme temperatures can alter adhesive properties, while high humidity levels may cause moisture-related issues that weaken bonds over time. It's vital to monitor these environmental conditions closely to ensure that your choice of eco-friendly adhesive or industrial-grade option performs at its best.

Misjudging Adhesive Cure Times

Another common mistake is misjudging how long an adhesive needs to cure before it reaches its optimal strength. Each type of adhesive has different curing characteristics, particularly when comparing traditional options with modern composite adhesives used in OTC packaging solutions. Rushing this process can lead to weak bonds and product failures; thus, always refer to manufacturer guidelines for cure times to avoid costly mistakes.

The Role of Water-Based VC Composite Adhesive

Water-based VC composite adhesives are making waves in the world of blister clamshell packaging adhesives, particularly due to their eco-friendly properties. These adhesives are formulated to minimize environmental impact while maintaining strong bonding capabilities. As consumers and manufacturers alike prioritize sustainability, the demand for eco-friendly adhesive solutions has surged, making water-based options a top choice.

Advantages for Eco-Friendly Packaging

One of the standout advantages of water-based VC composite adhesives is their low volatile organic compound (VOC) content, which significantly reduces air pollution during production and application. This makes them a prime candidate for companies looking to enhance their sustainability profile without compromising on performance. Additionally, these eco-friendly adhesives are often easier to clean up and dispose of, aligning perfectly with modern environmental regulations and consumer expectations.

Moreover, using eco-friendly adhesive options can also improve a brand's reputation among environmentally conscious consumers. By opting for these sustainable solutions in blister clamshell packaging, businesses not only contribute positively to the planet but also appeal to a growing market segment that values responsible practices. In short, choosing water-based VC composite adhesives is an investment in both quality and corporate responsibility.

Applications in Medical Disposable Devices

When it comes to medical disposable device adhesives, water-based VC composite adhesives offer versatility and reliability essential for safety-critical applications. These medical grade adhesives ensure that devices remain securely sealed while meeting stringent health regulations required in the healthcare sector. From syringes to IV bags, these adhesives provide robust performance without compromising patient safety or comfort.

In addition to their strong bonding capabilities, these medical disposable device adhesives are designed with biocompatibility in mind—meaning they won't cause adverse reactions when they come into contact with human tissues or fluids. This property is crucial when selecting the best adhesive glue for medical applications where compliance with regulatory standards is non-negotiable. Therefore, using water-based VC composite options can streamline manufacturing processes while ensuring adherence to necessary health guidelines.

Furthermore, as hospitals and clinics increasingly move toward sustainable practices themselves, incorporating eco-friendly adhesive solutions into medical disposable devices aligns with broader healthcare goals aimed at reducing waste and environmental impact. Manufacturers who embrace this shift will not only enhance product appeal but also contribute positively to public health initiatives focused on sustainability.

Performance Compared to Solvent-Based Options

When comparing water-based VC composite adhesives with traditional solvent-based options, several key differences come into play that highlight why many manufacturers are making the switch. Water-based formulations generally offer faster drying times and easier cleanup than solvent counterparts—making them more user-friendly across various industrial applications including OTC packaging processes. Additionally, their lower odor levels create a more pleasant working environment for employees during production.

Performance-wise, water-based VC composites have proven effective at providing strong adhesion suitable for diverse substrates commonly used in blister clamshell packaging applications—without sacrificing durability over time or under stress conditions like temperature fluctuations or humidity changes. While solvent-based alternatives may still dominate certain niches due to historical use patterns or specific bonding needs; advancements in water-based technology continue closing those gaps rapidly.

Ultimately though; choosing between these two types of adhesive boils down largely on specific application requirements alongside company values regarding environmental stewardship—after all; who wouldn’t want an adhesive solution that’s both high-performing AND kind on our planet? With ongoing innovations within this space; it’s clear that future trends will likely favor those embracing sustainable practices through effective product choices such as water-based composites!

Working with an Industrial Adhesive Supplier

Navigating the world of blister clamshell packaging adhesives can feel like a daunting task, especially when you're trying to find the right industrial adhesive supplier. The key is to seek out suppliers that specialize in OTC packaging and have a solid reputation for quality and reliability. Look for those who offer a range of options, including eco-friendly adhesives and medical grade adhesives, ensuring they can meet your diverse needs.

Finding Reliable Suppliers for OTC Packaging

When searching for reliable suppliers for OTC packaging, it's essential to consider their experience and expertise in the industry. A trustworthy supplier should be well-versed in various types of adhesives, including composite adhesive options that cater specifically to blister clamshell packaging. Additionally, check reviews and testimonials from other businesses to gauge their performance and customer service; after all, you want the best adhesive glue on your side.

Importance of Testing Adhesives Before Use

Before committing to any adhesive solution, particularly when it comes to medical disposable device adhesives or eco-friendly adhesive options, testing is crucial. Conducting thorough tests helps you understand how different blister clamshell packaging adhesives perform under various conditions such as temperature fluctuations or humidity levels. This step ensures that you select the best adhesive glue that will provide durability and safety in your final product.

Building Long-Term Relationships with Suppliers

Building long-term relationships with your industrial adhesive supplier can lead to significant advantages over time. A good partnership means access to consistent quality products like medical grade adhesives tailored specifically for your needs while also allowing for better pricing structures as trust develops. Plus, having a reliable supplier who understands your unique requirements can streamline production processes and enhance overall efficiency.

Conclusion

In the dynamic world of packaging, understanding the nuances of blister clamshell packaging adhesives is paramount. By recognizing common pitfalls and prioritizing safety, businesses can avoid costly mistakes that could jeopardize their products and reputation. The journey towards selecting the best adhesive glue should not only focus on performance but also on sustainability and compliance with industry standards.

Avoiding Costly Packaging Mistakes

One of the most significant challenges in using blister clamshell packaging adhesives is overlooking essential factors like surface preparation and environmental conditions. Failing to properly prepare surfaces can lead to weak bonds, resulting in product damage or customer dissatisfaction. Additionally, misjudging cure times can create delays in production, ultimately affecting your bottom line; hence a meticulous approach to adhesive application is crucial.

Prioritizing Safety with Medical Grade Adhesives

When it comes to medical disposable device adhesives, safety cannot be compromised. Medical grade adhesives are specifically formulated to meet stringent regulatory requirements, ensuring that they are safe for use in sensitive applications. By prioritizing these high-quality options, manufacturers can guarantee that their products are not only effective but also safe for end-users.

Embracing Sustainable Practices in Packaging

The shift towards eco-friendly adhesive solutions is more than just a trend; it's a necessary evolution in packaging practices. Using composite adhesive formulations can significantly reduce environmental impact while maintaining product integrity and performance standards. By partnering with an industrial adhesive supplier who shares a commitment to sustainability, companies can embrace innovative solutions that benefit both their operations and the planet.