Introduction

In an increasingly health-conscious world, the importance of food-safe adhesives cannot be overstated. These adhesives play a crucial role in ensuring that food packaging and processing materials meet stringent safety standards, thus protecting consumers from harmful substances. As we delve into the realm of adhesives suitable for direct food contact, we'll explore essential guidelines and best practices to make informed choices.

The Importance of Food-Safe Adhesives

Food-safe adhesives are indispensable in various sectors, from packaging to food processing. They not only ensure the integrity of food products but also prevent contamination that could lead to serious health risks. Choosing an adhesive approved for direct food contact is vital; it guarantees compliance with safety regulations and fosters consumer trust in your products.

Overview of Direct Food Contact Standards

Direct food contact standards are established by regulatory bodies to safeguard public health. These standards specify which materials and substances can safely interact with food items without posing a risk of contamination or chemical leaching. Understanding these guidelines is essential for manufacturers aiming to meet compliance requirements while maintaining product quality.

Key Considerations for Adhesive Selection

When selecting an adhesive, several key considerations come into play—chief among them being the adhesive’s intended use and application method. It’s important to understand usage limitations; not all adhesives are created equal when it comes to their interaction with food products. Additionally, factors such as environmental impact and ease of application should guide your decision-making process as you navigate the world of water base adhesive options and other suitable alternatives.

Choose an Adhesive Approved for Direct Food Contact

This not only guarantees the safety of the food but also aligns with regulatory standards that protect consumers. Choosing an adhesive approved for direct food contact can significantly impact both product integrity and brand reputation.

Understanding Certification Standards

Certification standards are essential in determining whether an adhesive is safe for use in direct contact with food. These standards, often set by organizations like the FDA or EFSA, specify the types of materials and chemicals that can be safely used in food-related applications. For instance, water base adhesives are frequently recognized due to their lower toxicity profiles compared to solvent-based options, making them a popular choice among manufacturers aiming to comply with stringent regulations.

Understanding these certification standards involves knowing what tests and criteria adhesives must meet before they can be deemed safe. Manufacturers should carefully review compliance documentation and seek out third-party certifications to ensure their products meet necessary guidelines. By prioritizing adherence to these standards, businesses not only safeguard consumer health but also enhance their credibility in a competitive market.

Notable Approved Adhesives

Among the various options available, several notable adhesives stand out as being particularly suitable for direct food contact applications. Water base adhesives have gained prominence due to their eco-friendly nature and compliance with health regulations, making them a favored choice in many industries. Other approved adhesives may include certain hot melts or pressure-sensitive adhesives that have been specifically formulated for safety when in contact with food.

It's crucial for manufacturers to stay updated on which specific products hold these approvals since formulations can change over time as new technologies emerge or regulations evolve. Engaging with suppliers who specialize in compliant materials can streamline this process considerably. By choosing recognized brands known for their commitment to safety, companies can confidently move forward knowing they’re using top-tier products.

Benefits of Compliance

The benefits of using adhesives that comply with direct food contact regulations extend beyond mere legal requirements; they play a vital role in consumer trust and brand loyalty as well. When businesses choose an adhesive approved for direct food contact, they signal to customers that quality and safety are top priorities—an important factor given today’s heightened awareness around health issues related to packaging materials.

Moreover, compliance often leads to fewer recalls or product liability claims associated with unsafe materials entering the supply chain—a significant financial advantage over time. Implementing quality control checks further reinforces this commitment by ensuring consistent performance throughout production runs while minimizing contamination risks during application processes.

In summary, selecting water base adhesive options or other certified alternatives is not just about meeting legal obligations; it’s about fostering a culture of responsibility within your organization while enhancing your brand's reputation as a leader in safe practices within the industry.

Understand Usage Limitations

Selecting a water base adhesive that meets the required standards is just the beginning; knowing when and how to use it effectively is equally important. Missteps in application can lead to contamination, undermining the very purpose of using an adhesive approved for direct food contact.

Identifying Safe Usage Scenarios

Identifying safe usage scenarios involves evaluating the specific conditions under which your water base adhesive will be applied. For instance, adhesives used in packaging must withstand varying temperatures and humidity levels without compromising their integrity or safety. Additionally, considering factors such as exposure time and surface compatibility can help ensure that you are making informed decisions about where and how to apply these adhesives.

In many cases, manufacturers provide guidelines on safe usage scenarios, which should be your go-to reference when selecting an adhesive approved for direct food contact. By adhering to these guidelines, you can avoid potential pitfalls that may arise from incorrect applications or environments that exceed the adhesive's limitations. Remember, understanding usage limitations not only protects consumers but also safeguards your brand’s reputation.

Common Misconceptions

One common misconception is that all water base adhesives are created equal when it comes to food safety—this couldn't be further from the truth! While some might boast certifications for direct food contact, others may not meet stringent safety standards due to their chemical compositions or intended uses. It’s essential to do thorough research and consult certification bodies before deciding on an adhesive.

Another misconception is that once you've chosen a compliant adhesive, you can use it anywhere without concern—wrong again! Just because an adhesive is approved doesn't mean it's suitable for every application scenario; each product has its own set of limitations based on environmental factors and material interactions. Being aware of these misconceptions helps maintain high standards in your production process while ensuring consumer safety.

Real-World Examples

Consider a bakery using a water base adhesive for sealing packaging on freshly baked goods; if they neglect temperature considerations during storage or transport, they could face adhesion failure or even contamination issues down the line. Another example would be a manufacturer producing meal kits who mistakenly assumes their chosen water base adhesive works well with all types of materials—only to find out later it reacts poorly with certain plastics used in their containers.

These real-world examples highlight the necessity of understanding usage limitations when working with adhesives approved for direct food contact. By learning from others' mistakes and implementing robust quality control checks throughout production processes, businesses can significantly reduce risks associated with improper adhesive applications. Ultimately, staying informed about safe usage scenarios empowers companies to make better choices in their material selections while enhancing overall consumer trust.

Control Adhesive Application

The right techniques can help minimize risks associated with contamination while maximizing the adhesive's performance. By focusing on safe application methods, you not only comply with regulations but also enhance your product's overall integrity.

Techniques for Safe Application

To start, using a water base adhesive is often recommended due to its lower toxicity and better compliance with food safety standards. Various application methods such as spraying, rolling, or brushing can be employed depending on the project requirements; however, it's crucial to maintain a clean workspace throughout the process. Additionally, ensuring that equipment is free from contaminants before use will further safeguard against any potential hazards.

Ensuring Even Distribution

Achieving an even distribution of adhesive is essential for optimal bonding and functionality in food-safe applications. When applying a water base adhesive, consider using tools designed specifically for uniform coverage—such as notched trowels or foam rollers—which can help prevent excess build-up in any one area. Regularly monitoring your application technique will ensure that you are adhering to best practices while also aligning with the directive to Choose an Adhesive Approved for Direct Food Contact.

Avoiding Contamination Risks

Contamination risks lurk around every corner when working with adhesives intended for direct food contact, so vigilance is key! Make it a point to keep all surfaces clean and well-maintained by implementing strict hygiene protocols during production processes.

Consider Barrier Layers

When it comes to ensuring the safety of food packaging, considering barrier layers is crucial. These layers act as a shield, preventing potential contaminants from migrating into food products. By incorporating barrier layers, manufacturers can enhance the overall integrity of their packaging while adhering to standards that require you to Choose an Adhesive Approved for Direct Food Contact.

Purpose of Barrier Layers

Barrier layers serve multiple purposes in food-safe applications. Primarily, they provide a protective barrier against moisture, gases, and other external factors that could compromise food quality or safety. Additionally, these layers can help maintain the effectiveness of adhesives used in packaging by minimizing direct contact between the adhesive and the food itself—an essential consideration when you Understand Usage Limitations.

Materials that Work Well

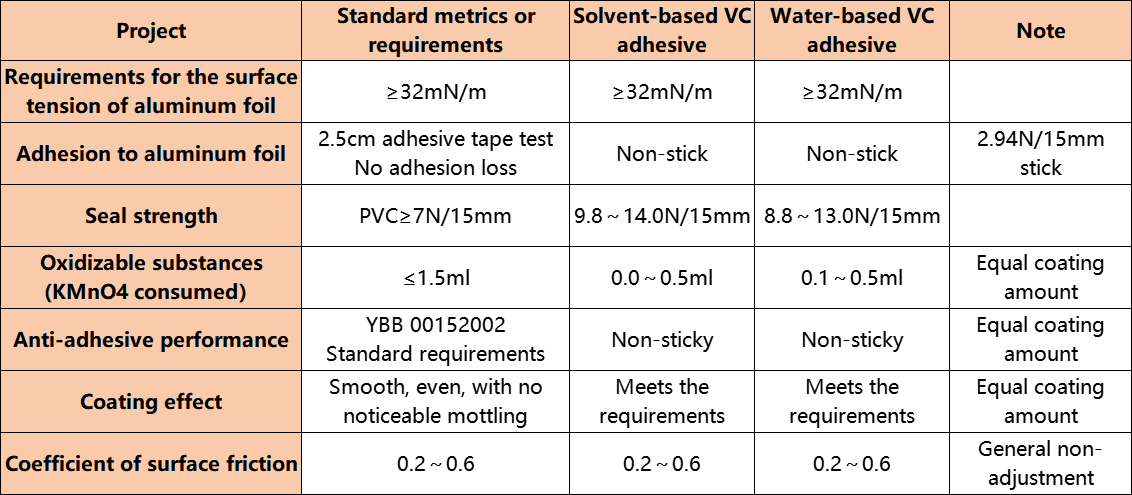

Several materials are effective as barrier layers in conjunction with water base adhesive formulations. Common choices include polyethylene terephthalate (PET), ethylene vinyl alcohol (EVOH), and aluminum foil—all known for their excellent barrier properties against oxygen and moisture. When selecting materials, it's important to ensure compatibility with your chosen adhesive while also meeting regulatory requirements for direct food contact.

Case Studies of Successful Applications

A notable case study involves a leading snack manufacturer that implemented a multi-layer approach using water base adhesive combined with EVOH barrier films in their packaging process. This strategy not only extended shelf life but also maintained product freshness without compromising safety standards—showcasing how effective Control Adhesive Application can be when paired with appropriate materials. Another example is a dairy company utilizing aluminum foil barriers to prevent spoilage; this highlights how successful applications can result from thorough research and Maintain Transparent Supplier Communication regarding material choices.

Maintain Transparent Supplier Communication

In the world of food-safe adhesives, maintaining transparent communication with suppliers is crucial for ensuring product safety and compliance. Suppliers play a vital role in providing information about their materials, including whether they are suitable for direct food contact. By fostering open dialogue, businesses can better understand the full scope of adhesive properties and adhere to industry standards.

Importance of Supplier Transparency

Supplier transparency is essential when choosing an adhesive approved for direct food contact. It allows manufacturers to verify that their water base adhesive meets safety regulations and performance expectations. Moreover, clear communication can help identify any potential issues early on, preventing costly mistakes down the line.

Questions to Ask Your Supplier

When engaging with suppliers about your adhesive needs, it's important to ask targeted questions that cover key areas like certification and usage limitations. Inquire whether their water base adhesive has been tested for direct food contact approval and what certifications it holds. Additionally, understanding how they control adhesive application during production can provide valuable insights into safety practices.

Building Trust in Your Supply Chain

Building trust within your supply chain hinges on consistent communication and verification of claims made by suppliers regarding their products. Regularly checking in with suppliers about new developments or changes to their water base adhesive formulations helps maintain a robust relationship based on transparency. Ultimately, this trust ensures that you can confidently implement quality control checks without second-guessing the materials used in your products.

Implement Quality Control Checks

Ensuring the safety and effectiveness of food-safe adhesives is paramount, and implementing rigorous quality control checks is a vital step in this process. Regular assessments help identify any issues that might arise during production or application, especially when using products like water base adhesive. By prioritizing quality control, manufacturers can maintain compliance with standards for direct food contact while also safeguarding consumer health.

Key Quality Control Measures

Key quality control measures begin with establishing a robust testing framework that evaluates the performance and safety of adhesives used in food applications. For instance, companies should regularly test their water base adhesive to ensure it meets the required standards for direct food contact, as well as verify its adhesion properties under various conditions. Additionally, implementing batch tracking allows for quick identification of any problematic batches and facilitates swift corrective actions.

Regular Testing Protocols

Regular testing protocols are essential to ensure that adhesives perform reliably throughout their intended lifecycle. This includes conducting tests on adhesion strength, chemical resistance, and potential leaching of harmful substances from the adhesive into food products. Companies should also establish a schedule for routine testing of their water base adhesive to align with industry best practices and regulatory requirements while staying informed about any updates in standards related to direct food contact.

Documenting and Reporting Results

Documenting and reporting results from quality control checks not only helps maintain transparency but also builds trust within the supply chain regarding adhesive safety practices. Keeping detailed records allows manufacturers to track performance trends over time, making it easier to spot anomalies or areas needing improvement related to usage limitations or application techniques. Furthermore, sharing these results with suppliers fosters open communication about product reliability and encourages collaboration on solutions when challenges arise.

Conclusion

In wrapping up our exploration of food-safe adhesives, it’s essential to remember that not all adhesives are created equal. Choosing an adhesive approved for direct food contact is paramount, as this ensures safety and compliance with relevant standards. Moreover, understanding usage limitations helps prevent potential mishaps that could compromise food safety.

Recap of Adhesive Safety Practices

Throughout our discussion, we emphasized the importance of selecting adhesives that are certified for direct food contact. Utilizing water base adhesive options can be a smart choice due to their lower toxicity and environmental impact. Additionally, controlling adhesive application is crucial; techniques like ensuring even distribution help mitigate contamination risks while maintaining product integrity.

The Future of Eco-Friendly Adhesives

The future looks promising for eco-friendly adhesives, particularly as consumer demand increases for sustainable products in the food industry. Innovations in water base adhesive formulations are paving the way for safer, greener choices that comply with stringent regulations regarding direct food contact. As manufacturers prioritize sustainability alongside safety, we can expect a wider range of compliant options that meet both ecological and health standards.

Final Thoughts on Responsible Adhesive Use

Responsible adhesive use encompasses a holistic approach that includes maintaining transparent supplier communication and implementing quality control checks throughout the production process. By asking suppliers about their certifications and testing protocols, businesses can build trust within their supply chains while ensuring product safety from start to finish. Ultimately, integrating these practices will foster a culture of responsibility in the industry—one where consumer health and environmental sustainability go hand in hand.