Introduction

In the world of materials, PVC adhesive film stands out for its versatility and practicality. This remarkable product, often referred to as PVC vinyl film, is a synthetic polymer that boasts a unique combination of durability and flexibility, making it an ideal choice for various applications. Whether you're looking to enhance your crafting projects or seeking reliable packaging solutions, understanding the nuances of PVC adhesive film is essential.

Understanding PVC Adhesive Film

PVC adhesive film is composed primarily of polyvinyl chloride (PVC), a robust material known for its resistance to wear and tear. The film can be coated with different types of adhesives, allowing it to adhere effectively to various surfaces. When evaluating how to judge whether it is a high-quality PVC adhesive film, consider factors such as adhesion strength and durability against environmental conditions.

Applications of PVC Vinyl Film

The applications of PVC vinyl film are vast and varied, ranging from packaging solutions that protect products during transport to decorative projects that add flair to any space. In industrial settings, this versatile material finds use in automotive components where durability is paramount. Additionally, craft enthusiasts appreciate its ease of use and adaptability in creating unique designs.

Benefits of Using PVC Adhesive

When considering the advantages of PVC adhesive film, one must highlight its cost-effectiveness compared to other materials like PET adhesive films or traditional adhesives. Its long-lasting nature ensures that projects remain intact over time without frequent replacements or repairs. Furthermore, with innovations in application methods and machines, working with PVC vinyl film has never been easier or more efficient.

What is PVC Adhesive Film

PVC adhesive film is a versatile material primarily composed of polyvinyl chloride (PVC), which is known for its durability and flexibility. This film often features an adhesive backing that allows it to bond effectively to various surfaces, making it suitable for a wide range of applications. Understanding the composition and characteristics of PVC vinyl film is crucial for evaluating its performance in different settings.

Composition of PVC Vinyl Film

The primary component of PVC vinyl film is polyvinyl chloride, a synthetic plastic polymer that offers excellent resistance to chemicals, moisture, and UV light. This composition not only enhances the film's durability but also contributes to its lightweight nature, making it easier to handle during application methods and machines. Additionally, the formulation can include plasticizers and stabilizers that enhance flexibility and longevity, ensuring that the advantages of PVC adhesive film are fully realized in practical use.

Types of Adhesives Used

When it comes to adhering PVC vinyl film to surfaces, various types of adhesives can be employed depending on the specific requirements of the project. Common options include pressure-sensitive adhesives (PSAs), which provide immediate adhesion upon contact without needing additional heat or solvent activation. Other adhesive types such as solvent-based or water-based formulations may also be used by adhesive coating manufacturers for more specialized applications, ensuring that users can select an option tailored to their needs.

Comparison with Other Materials

When comparing PVC adhesive film with other materials like PET adhesive films or traditional paper-based adhesives, several factors come into play. While PET films offer certain advantages in terms of clarity and strength, they often lack the same level of flexibility as their PVC counterparts. Furthermore, PVC vinyl films tend to be more cost-effective than many alternatives while still providing excellent durability—making them a popular choice among consumers looking for high-quality solutions in various applications.

Key Applications of PVC Vinyl Film

PVC vinyl film is a versatile material that finds its way into various industries due to its unique properties and advantages. From packaging to crafting and automotive applications, the uses are as diverse as they are practical. Understanding these key applications can help you appreciate why this adhesive film is a go-to choice for many professionals.

Packaging Solutions

One of the most prominent applications of PVC vinyl film is in packaging solutions. This material offers excellent barrier properties, ensuring products remain fresh and protected from external elements. The advantages of PVC adhesive film in packaging include durability, flexibility, and the ability to create visually appealing designs that attract consumers' attention.

In addition to food packaging, PVC vinyl film is widely used for wrapping consumer goods and industrial products. This adaptability makes it a favorite among adhesive coating manufacturers who seek materials that can cater to various product requirements. When evaluating product prospects, consider how well PVC vinyl film can enhance your packaging strategy while maintaining quality standards.

Decorative and Craft Projects

Craft enthusiasts have embraced PVC vinyl film for its versatility in decorative projects. From scrapbooking to home décor, this adhesive pvc material allows for creativity without compromising on quality or durability. Its ease of use means that whether you're creating custom decals or intricate designs, the application methods and machines available make the process straightforward.

The vibrant colors and patterns available in PVC vinyl films make them ideal for personalizing items like mugs, t-shirts, or even furniture pieces. Moreover, understanding how to judge whether it is a high-quality PVC adhesive film can save you time and effort when selecting materials for your next project. The right choice ensures longevity while enhancing the aesthetic appeal of your crafts.

Automotive and Industrial Uses

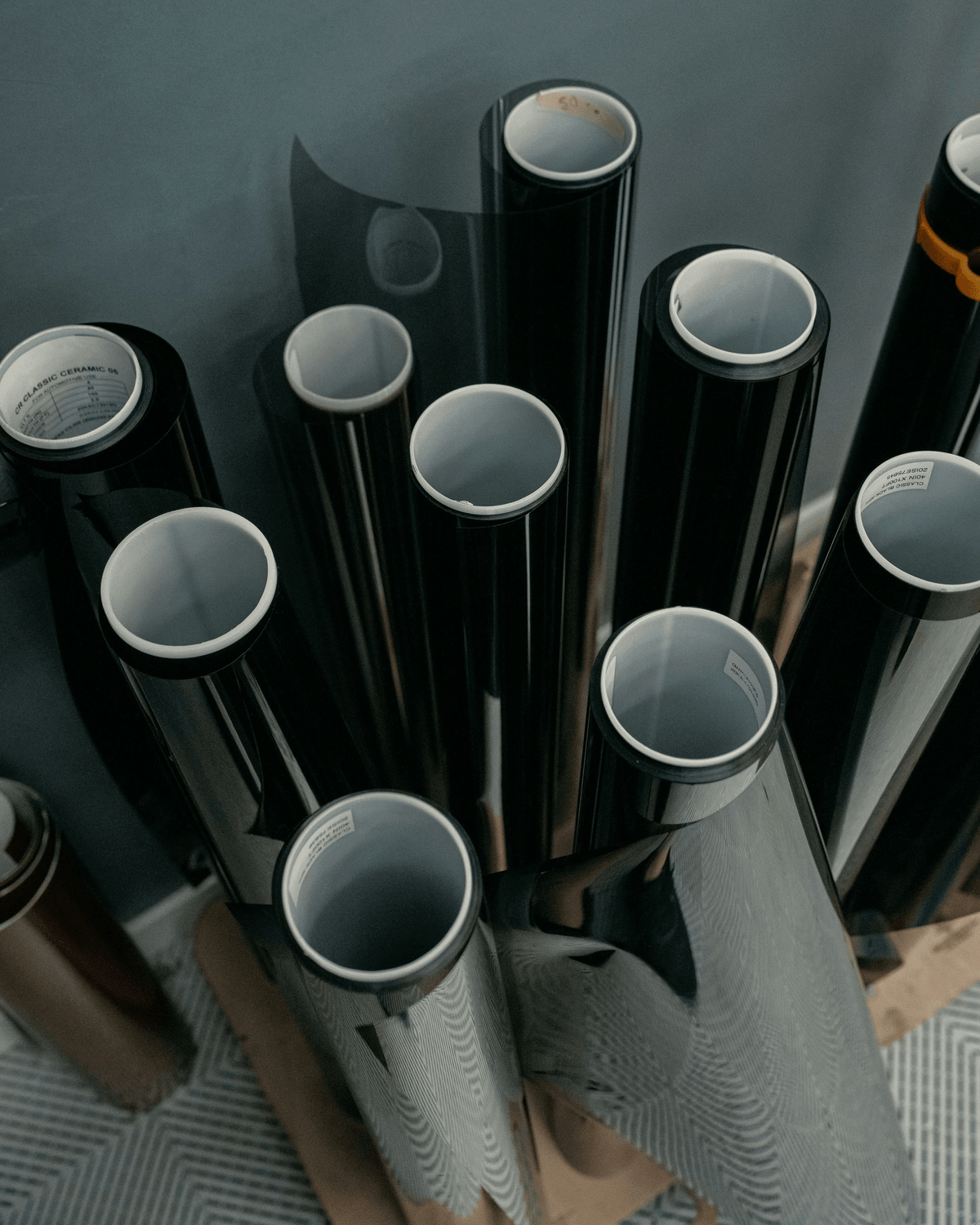

In the automotive industry, PVC vinyl film serves multiple purposes ranging from protective wraps to interior finishes. Its resistance to abrasion and chemicals makes it an ideal choice for car enthusiasts looking to customize their vehicles with durable graphics or protective coatings. Additionally, industrial uses extend beyond aesthetics; companies rely on this material for safety signage and equipment labeling due to its visibility and resilience.

The benefits of using high-quality adhesive pvc films in these settings cannot be overstated; they offer long-lasting performance under various environmental conditions while maintaining their appearance over time. As industries evolve towards more innovative solutions, understanding product prospects within automotive applications remains crucial for manufacturers seeking an edge over competitors. By leveraging advancements in technology alongside traditional uses of PVC vinyl film, businesses can ensure they meet market demands effectively.

Advantages of PVC Adhesive Film

PVC adhesive film has carved a niche for itself in various industries, and it's easy to see why. The advantages of PVC adhesive film make it a go-to choice for many applications, from crafting to packaging. Let's dive into the key benefits that set this material apart from others.

Durability and Longevity

One of the standout features of PVC vinyl film is its remarkable durability and longevity. This material is resistant to wear and tear, making it ideal for both indoor and outdoor applications where exposure to elements can be a concern. When you invest in high-quality PVC adhesive film, you're ensuring that your projects will stand the test of time, reducing the need for frequent replacements.

Moreover, manufacturers like adhesive coating manufacturers have developed advanced formulations that enhance the resilience of PVC films against UV rays, moisture, and chemicals. This means your decorative projects or packaging solutions won’t just look good initially; they’ll maintain their integrity over time. In short, durability is not just an advantage; it’s a hallmark of quality when it comes to choosing your PVC adhesive options.

Cost-Effectiveness

Cost-effectiveness is another compelling reason to opt for PVC vinyl film in various applications. Compared to other materials like PET adhesive or traditional paper products, PVC offers superior performance without breaking the bank. Its long lifespan means fewer replacements are needed over time—what’s not to love about saving money while still achieving excellent results?

Additionally, with innovations in production techniques by leading adhesive coating manufacturers, the price point for high-quality PVC films has become increasingly accessible. This makes it easier than ever for businesses and hobbyists alike to incorporate this versatile material into their projects without overspending. When evaluating product prospects in terms of budget constraints, you’ll find that investing in PVC adhesive film pays off handsomely.

Versatility in Usage

The versatility in usage of PVC vinyl film cannot be overstated—it truly shines across various sectors! Whether you're looking at packaging solutions or decorative crafts, this material adapts beautifully to diverse Application Methods and Machines. Its ease of application allows users—from professionals to DIY enthusiasts—to achieve stunning results with minimal effort.

Moreover, its compatibility with different surfaces expands its usability even further; you can apply it on wood, metal, glass—virtually anywhere! As trends evolve within industries utilizing adhesive pvc products, we see even more innovative uses emerging daily—making it an exciting time for anyone interested in exploring what this adaptable material can do!

How to Properly Apply PVC Vinyl Film

Applying PVC vinyl film may seem daunting, but with the right techniques and tools, you can achieve a professional finish. Proper application not only enhances the aesthetic appeal of your project but also maximizes the **Advantages of PVC Adhesive Film**, ensuring durability and longevity. Let's dive into the essential steps for a successful application.

Surface Preparation Techniques

Before applying adhesive PVC film, surface preparation is crucial for optimal adhesion. Start by cleaning the surface thoroughly; any dust, grease, or debris can compromise the bond between the film and the substrate. Use a mild detergent solution followed by a rinse with clean water to remove residues, then allow it to dry completely before proceeding.

Next, assess whether the surface is smooth or textured; this will influence your choice of adhesive coating manufacturers and application methods. For rough surfaces, sanding may be necessary to create a smoother base for adhesion. Finally, consider using a primer designed for vinyl films if you're working with porous materials like wood or concrete—this ensures better adhesion and enhances overall performance.

Application Tools and Techniques

When it comes to applying your PVC vinyl film, having the right tools on hand can make all the difference in achieving an immaculate finish. Essential tools include a utility knife for precise cutting, a squeegee to eliminate air bubbles during application, and measuring tape for accurate sizing. Depending on your project scale, you might also consider investing in Application Methods and Machines that automate parts of this process.

To apply adhesive PVC effectively, begin by peeling back just a portion of the backing paper while aligning it carefully with your intended design placement. Gradually press down while using your squeegee to push out air bubbles from underneath—start from one side and work your way across for best results. If you encounter any stubborn bubbles or wrinkles during application, don’t panic! A small pinhole can help release trapped air without damaging your film.

Curing and Drying Process

Once you've applied your PVC vinyl film smoothly onto its surface, it's time to focus on curing and drying processes that ensure long-lasting adhesion. Allowing adequate time for curing is essential; this involves letting any adhesives set properly according to manufacturer recommendations—typically ranging from 24 hours up to several days depending on environmental conditions.

During this period, avoid exposing newly applied films to moisture or extreme temperatures as these factors could weaken bonds formed during curing timeframes—especially important if you're working with pet adhesive products that require specific care instructions post-application. After curing has completed successfully without disturbances from external elements like humidity levels or temperature fluctuations affecting performance—your project will be ready!

In summary: proper surface preparation techniques combined with effective application tools lead you toward achieving remarkable results when working with high-quality PVC adhesive films! Don't forget about those all-important curing times—patience truly pays off when enjoying durable outcomes!

Innovations in PVC Adhesive Film

The world of PVC adhesive film is constantly evolving, with innovations that enhance its performance and broaden its applications. From advanced resin technologies to eco-friendly alternatives, the industry is witnessing significant changes that cater to both consumer demands and environmental considerations. Let's delve into these exciting developments.

Chemix's Anionic Resin Technology

One of the standout advancements in PVC vinyl film is Chemix's anionic resin technology, which promises to revolutionize adhesive formulations. This cutting-edge technology enhances the adhesion properties of the film, making it more effective for various applications while ensuring a smoother application process. By improving the bonding strength and flexibility of adhesive PVC, this innovation allows for better performance across diverse environments, from crafting projects to industrial uses.

Moreover, Chemix's technology contributes to the overall durability and longevity of PVC adhesive films, reinforcing their advantages over traditional options. As users increasingly look for high-quality products that stand up to wear and tear, this development places Chemix at the forefront of adhesive coating manufacturers within the industry. With a focus on enhancing product prospects through innovative solutions like anionic resins, it’s clear that Chemix is paving the way for future advancements in PVC vinyl film.

Eco-Friendly Alternatives

As sustainability becomes a priority across industries, eco-friendly alternatives in PVC vinyl film are gaining traction among consumers and manufacturers alike. These alternatives often utilize bio-based materials or non-toxic additives that reduce environmental impact without sacrificing performance. By choosing eco-friendly adhesive PVC options, users can enjoy many benefits while supporting a greener planet.

Additionally, these innovations often come with improved safety profiles for both applicators and end-users—an essential consideration in today’s market where health regulations are becoming stricter. As awareness grows about sustainable practices within packaging solutions and decorative projects, eco-friendly options are not just trends; they’re becoming essential components of responsible manufacturing practices. This shift towards sustainability reflects broader industry trends focused on reducing waste and promoting recyclable materials.

Trends in the Industry

The trends shaping the future of PVC adhesive film reflect wider shifts in consumer preferences towards versatility and customization. More businesses are adopting Application Methods and Machines that allow them to tailor their films according to specific needs—whether it's custom sizes or unique finishes—making them highly adaptable across sectors such as automotive or crafts. The ability to personalize products enhances user satisfaction while also allowing manufacturers to differentiate themselves in a competitive market.

Moreover, there's an increasing emphasis on how to judge whether it is a high-quality PVC adhesive film amidst numerous offerings available today. Consumers are becoming more discerning about product features such as adhesion strength, durability under varying conditions, and overall aesthetic appeal—key factors influencing purchasing decisions in this dynamic landscape. Staying ahead means keeping an eye on these trends while continuously innovating product lines to meet evolving expectations.

Conclusion

In wrapping up our exploration of PVC adhesive film, it's clear that this versatile material brings a wealth of benefits to various applications. From its durability and cost-effectiveness to its ease of use in both industrial and creative projects, the advantages of PVC adhesive film are numerous. As we look towards the future, the potential for innovations in adhesive coating manufacturers and application methods only adds to its appeal.

Recap of PVC Adhesive Film Benefits

The advantages of PVC adhesive film extend beyond mere functionality; they include remarkable durability, which ensures that products made with this material stand the test of time. Additionally, the affordability makes it an attractive choice for businesses and hobbyists alike, allowing for extensive use without breaking the bank. Finally, its versatility means that whether you're working on packaging solutions or decorative crafts, PVC vinyl film can meet your needs seamlessly.

Future Outlook for PVC Vinyl Film

Looking ahead, product prospects for PVC vinyl film appear bright as industries continue to seek innovative solutions that balance performance with sustainability. The rise of eco-friendly alternatives will likely influence how adhesive manufacturers approach production while maintaining quality standards. As trends evolve toward more specialized applications and advanced technologies like Chemix's anionic resin technology emerge, we can expect even greater versatility from this already adaptable material.

Final Thoughts on Choosing the Right Film

When selecting a high-quality PVC adhesive film, it's essential to judge based on several criteria: thickness, adhesion strength, and resistance to environmental factors like UV light or moisture. Consulting reputable adhesive coating manufacturers can provide valuable insights into product specifications and performance metrics tailored to your specific needs. Ultimately, whether you're utilizing it in crafting or industrial applications, choosing the right type will ensure you harness all the benefits this dynamic material has to offer.