Introduction

In the world of tile installation, the choice of adhesive can make all the difference between a flawless finish and a frustrating fiasco. High viscosity tile adhesives have emerged as a popular option for those looking to achieve strong bonds and durable results with ceramic tiles. Understanding how these premium tile adhesives work is key to selecting the right product for your project.

Understanding High Viscosity Tile Adhesives

High viscosity tile adhesives are specially formulated to provide excellent adhesion properties while maintaining a thicker consistency that allows for better control during application. This unique characteristic not only enhances the bonding strength between tiles and substrates but also minimizes sagging, making them ideal for vertical installations. When working with ceramic tile adhesive, choosing high viscosity options can lead to more reliable results in both residential and commercial settings.

The Role of OEM Customization in Adhesives

Original Equipment Manufacturers (OEMs) play an essential role in the customization of adhesives tailored to specific applications or customer needs. By collaborating closely with manufacturers, users can obtain premium tile adhesives that meet precise performance criteria, ensuring optimal results in various environments. This level of customization can significantly enhance the effectiveness of ceramic tile adhesive, allowing for improved durability and application ease.

Advantages of Premium Tile Adhesives

Investing in premium tile adhesives offers numerous benefits that extend beyond mere adhesion capabilities. These products often boast enhanced durability, resistance to moisture, and superior flexibility compared to standard options on the market. Additionally, using high-quality ceramic tile adhesive can reduce long-term maintenance costs by minimizing repairs and replacements due to failures or damage.

The Science Behind Ceramic Tile Adhesive

Understanding the science behind ceramic tile adhesive is crucial for anyone looking to achieve a flawless installation. These adhesives are designed to create a strong bond between tiles and substrates, ensuring durability and longevity. Premium tile adhesives often incorporate advanced formulations that enhance their performance and adaptability in various conditions.

Composition and Properties

Ceramic tile adhesive typically consists of a blend of polymers, fillers, and additives that contribute to its overall effectiveness. The polymers provide flexibility and adhesion, while fillers enhance the adhesive's workability and strength. Premium tile adhesives may also include special additives that improve water resistance, reduce drying time, or increase open time, making them suitable for various applications.

The properties of these adhesives can vary significantly based on their composition. For instance, some ceramic tile adhesives are designed specifically for wet environments like bathrooms or kitchens, while others excel in high-traffic areas due to their enhanced durability. Understanding these properties helps consumers choose the right product for their specific needs.

Viscosity and Performance Metrics

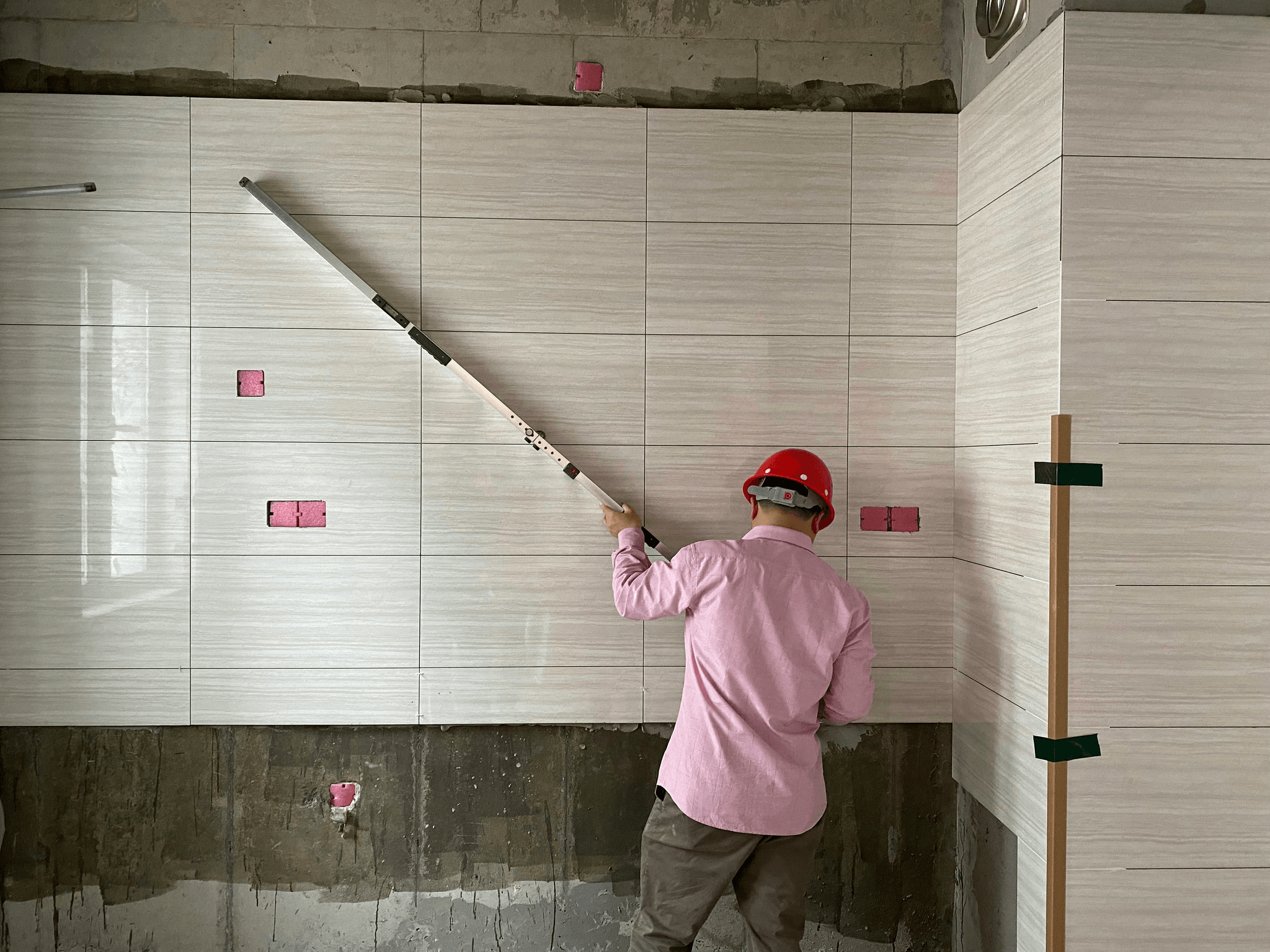

Viscosity is a critical factor when it comes to ceramic tile adhesive performance metrics; it determines how easily the adhesive can be applied and how well it will hold tiles in place once set. High viscosity adhesives offer better vertical hold during application, reducing slippage of larger tiles before they cure completely. This characteristic is particularly beneficial when working with heavy materials or intricate designs where precision is key.

Performance metrics such as shear strength, tensile strength, and flexibility also play an essential role in evaluating the effectiveness of premium tile adhesives. These metrics inform users about how well an adhesive will perform under different conditions—like temperature fluctuations or moisture exposure—ensuring that installations remain intact over time. By understanding these factors, professionals can make informed decisions when selecting ceramic tile adhesives.

Benefits of High Viscosity

High viscosity ceramic tile adhesives come with several advantages that make them a preferred choice among professionals in the field. One significant benefit is their ability to provide excellent coverage without excessive sagging; this ensures that even large-format tiles can be installed securely without fear of slipping during application.

Additionally, high viscosity formulations often lead to improved bonding capabilities with various substrates—whether it's concrete, plywood, or existing tiles—allowing for more versatile applications across different projects. This versatility means fewer product changes on-site and less hassle for installers seeking efficient solutions.

Finally, using premium high viscosity tile adhesives not only enhances installation quality but also contributes to long-term durability against environmental stresses like moisture or temperature changes. Thus, investing in high viscosity options ultimately pays off by delivering lasting results that stand up against wear over time.

Chemix's Water-Based Resin Solution

Chemix has developed a revolutionary water-based resin solution that is transforming the landscape of ceramic tile adhesive applications. This innovative approach not only enhances the performance of Premium Tile Adhesives but also aligns with eco-friendly practices, making it a top choice for environmentally conscious consumers and professionals alike. The unique properties of water-based resins contribute to sustainable construction methods while ensuring high-quality results in tile installations.

What Makes Water-Based Resins Eco-Friendly

Water-based resins stand out as an eco-friendly alternative due to their low volatile organic compound (VOC) content. Unlike traditional solvent-based adhesives, these resins minimize harmful emissions, promoting better indoor air quality and reducing environmental impact during production and application. Additionally, water-based formulations are often easier to clean up and dispose of, making them safer for both users and the planet.

Applications in Tile Adhesives

The versatility of Chemix's water-based resin solution makes it ideal for various applications within the realm of ceramic tile adhesive products. Whether you’re working on residential or commercial projects, this eco-friendly option provides excellent adhesion and flexibility across different substrates. From wall tiles to floor installations, using Premium Tile Adhesives with water-based resins ensures long-lasting performance without compromising on sustainability.

Durability and Non-Toxic Benefits

One might wonder if eco-friendly options can match the durability offered by traditional adhesives; however, Chemix’s water-based resin solution proves otherwise. These Premium Tile Adhesives deliver exceptional bonding strength while remaining non-toxic, making them safe for use in homes with children or pets. By choosing ceramic tile adhesive products powered by water-based resins, you’re not only opting for superior performance but also contributing to a healthier living environment.

Choosing the Right Premium Tile Adhesive

Selecting the right premium tile adhesive can make or break your tiling project. With a plethora of options available, it’s crucial to understand what differentiates each product and how they align with your specific needs. Factors such as the type of tiles, substrate material, environmental conditions, and intended use all play significant roles in making an informed choice.

Factors to Consider in Selection

When choosing a ceramic tile adhesive, start by considering the type of tile you’re working with—ceramic, porcelain, or natural stone all have unique requirements. Next, evaluate the substrate; whether it's concrete, drywall, or a wet area like a shower can drastically influence your adhesive selection. Additionally, think about factors like setting time and flexibility; some projects may require faster drying times while others benefit from more pliable adhesives that accommodate movement.

Comparing Different Products on the Market

With so many premium tile adhesives on the market today, it’s essential to compare their features closely. Look for products that provide detailed specifications regarding their composition and performance metrics—this will help you assess their suitability for your project. Also consider user reviews and case studies; sometimes real-world experiences reveal more than technical data ever could about how a ceramic tile adhesive performs under various conditions.

Customized Solutions for Specific Needs

Not every tiling job is one-size-fits-all; that's where customized solutions come into play! Many manufacturers offer tailored formulations of premium tile adhesives designed to meet specific challenges—be it high moisture areas or extreme temperature fluctuations. Engaging with suppliers who specialize in customized products can ensure that you find an adhesive perfectly suited for your unique project requirements.

Installation Tips for Optimal Performance

When it comes to achieving the best results with ceramic tile adhesive, proper installation is key. The way you prepare surfaces and apply adhesives can significantly impact the longevity and effectiveness of your tile work. Let's dive into some essential tips that will ensure your premium tile adhesives perform at their best.

Preparing Surfaces for Adhesive Application

The first step in any successful tiling project is to prepare the surface meticulously. Ensure that the area is clean, dry, and free from dust or debris; any contaminants can prevent proper adhesion of your ceramic tile adhesive. If you're working with a porous substrate, consider sealing it beforehand to create a stable base for the premium tile adhesives.

Additionally, check for any unevenness in the surface; using a leveling compound can help achieve a smooth and even substrate. Remember, even minor imperfections can lead to complications down the line, such as cracked tiles or peeling adhesive. Taking these preparatory steps seriously will set you up for success when applying your chosen adhesive.

Application Techniques for Tile Adhesives

Once you've prepared your surfaces, it's time to focus on how you apply your ceramic tile adhesive. Using a notched trowel is crucial; it helps ensure an even spread of adhesive while allowing air pockets to escape during application. When spreading the premium tile adhesives, maintain consistent pressure and angle to create uniform ridges that aid in bonding.

It's also essential to work in small sections at a time—this way, you can lay tiles before the adhesive begins to set and lose its tackiness. For added security, consider back-buttering larger tiles by applying a thin layer of adhesive directly onto them before pressing them into place on the troweled surface. This technique enhances adhesion and ensures that every inch is securely bonded.

Common Mistakes to Avoid

Even seasoned DIYers make mistakes when installing ceramic tile adhesive; however, being aware of common pitfalls can save you from headaches later on! One major error is applying too much or too little adhesive—either extreme can lead to poor bonding or excess squeeze-out that looks unsightly once dried. It's vital always to follow manufacturer guidelines regarding coverage rates with premium tile adhesives.

Another mistake involves neglecting drying times between layers or before grouting; rushing this process may compromise both adhesion strength and overall durability of your installation. Lastly, avoid walking on freshly laid tiles until they are fully cured—patience pays off! By steering clear of these common blunders, you'll be well on your way toward achieving stunning results with your ceramic tiles.

Innovations in Tile Adhesive Technology

The world of tile adhesives is evolving at a rapid pace, driven by new formulations and a growing demand for sustainability. Innovations in ceramic tile adhesive technology are reshaping how we approach installations, ensuring better performance and environmental responsibility. As the market for premium tile adhesives expands, manufacturers are focusing on creating products that not only meet stringent performance standards but also cater to eco-conscious consumers.

Emerging Trends in Adhesive Formulations

One of the most exciting trends in adhesive formulations is the shift towards hybrid systems that combine the best features of traditional and modern materials. These innovative ceramic tile adhesives often incorporate advanced polymers that enhance adhesion while maintaining flexibility and durability. Additionally, manufacturers are increasingly experimenting with bio-based components that reduce reliance on petrochemicals, resulting in more sustainable premium tile adhesives.

Another notable trend is the development of quick-setting formulas designed to speed up installation processes without sacrificing quality. This allows contractors to complete projects faster while ensuring strong bonds between tiles and substrates. Moreover, advancements in technology have led to improved moisture resistance and temperature tolerance, making these adhesives suitable for a wider range of applications.

The Future of Sustainable Adhesives

The future of sustainable adhesives looks promising as industry players prioritize eco-friendly practices and materials in their product lines. Ceramic tile adhesive manufacturers are actively exploring renewable resources to create high-performance options that minimize environmental impact without compromising effectiveness. This includes using recycled materials or naturally derived ingredients, which can significantly reduce carbon footprints associated with production.

Moreover, regulatory pressures and consumer preferences are driving innovation towards low-VOC (volatile organic compounds) formulations that promote healthier indoor air quality. As awareness grows about the importance of sustainability, we can expect an influx of premium tile adhesives designed specifically with eco-friendliness in mind—making it easier than ever for consumers to choose products that align with their values.

Case Studies of Successful Applications

Several successful case studies highlight the effectiveness of innovative ceramic tile adhesive solutions across various projects. For example, a recent commercial renovation utilized a new hybrid adhesive formulation that provided exceptional bond strength while allowing for rapid installation—reducing downtime significantly for business owners eager to reopen their doors. The project not only showcased the versatility of premium tile adhesives but also demonstrated how modern innovations can lead to cost savings through efficient application methods.

In another instance, a residential project employed an eco-friendly adhesive made from bio-based materials for its kitchen backsplash installation. Homeowners reported satisfaction not only with the aesthetic appeal but also with peace of mind knowing they chose a product prioritizing health and sustainability—an essential consideration today as more people become environmentally conscious.

Overall, these case studies exemplify how embracing innovations within ceramic tile adhesive technology can lead to successful outcomes across diverse applications while paving the way for future advancements in this vital industry.

Conclusion

In the ever-evolving world of construction and design, high viscosity tile adhesives have emerged as a game-changer for both professionals and DIY enthusiasts alike. These premium tile adhesives not only enhance the bonding strength but also offer improved workability, making them a preferred choice in various applications. As we wrap up our exploration, it’s clear that understanding the benefits of high viscosity is essential for anyone looking to achieve durable and aesthetically pleasing tile installations.

Recap of High Viscosity Benefits

High viscosity ceramic tile adhesive provides superior performance by ensuring that tiles adhere firmly to surfaces without sagging or slipping during installation. This characteristic is particularly beneficial when working with larger or heavier tiles, where traditional adhesives might fall short. Moreover, the enhanced adhesion properties contribute to long-lasting results, reducing the risk of costly repairs down the line.

The Importance of Customization in Adhesives

Customization plays a pivotal role in maximizing the performance of premium tile adhesives tailored to specific project needs. Whether you require flexibility for movement or added moisture resistance for wet areas, customized formulations ensure that each application meets unique requirements effectively. As manufacturers increasingly embrace OEM customization, clients can find solutions that perfectly align with their project goals while maintaining high standards of quality.

The Future of Eco-Friendly Tile Adhesives

The push toward sustainability is reshaping the adhesive industry, especially with eco-friendly ceramic tile adhesive gaining traction among environmentally conscious consumers and contractors. Innovations such as water-based resins are paving the way for safer options without compromising on performance or durability. As we look ahead, it’s clear that eco-friendly premium tile adhesives will continue to evolve, offering sustainable solutions that meet both functional and environmental demands.