Introduction

In the world of packaging, adhesives play a crucial role that often goes unnoticed. They are the unsung heroes that hold products securely, ensuring they arrive at their destination intact and ready for use. Among various adhesive options, aluminum blister adhesive stands out for its unique properties and applications, particularly in the pharmaceutical sector.

Why Adhesives Matter in Packaging

Adhesives are fundamental to packaging because they provide structural integrity and protection for products. Without the right adhesive, packages can fail, leading to damaged goods and dissatisfied customers. Aluminum blister adhesive is especially important in industries where safety and product preservation are paramount.

The Importance of Choosing the Right Adhesive

Selecting the right adhesive can make or break your packaging strategy; it directly impacts not only functionality but also consumer perception. A poor choice may lead to compromised product quality or ineffective sealing, while a well-chosen aluminum blister adhesive ensures reliability and enhances user experience. Understanding your specific needs is essential for making informed decisions about which adhesive will best serve your products.

Overview of Common Adhesive Types

There’s a plethora of adhesives available today—each designed for different applications and materials. Water-based resins are popular for their eco-friendliness, while solvent-based options offer strong bonding capabilities under challenging conditions.

Understanding Aluminum Blister Adhesive

Aluminum blister adhesive is a specialized bonding agent used primarily in the packaging industry, particularly for pharmaceuticals. This adhesive is designed to securely seal aluminum foil to various substrates, ensuring that products remain protected from external elements while maintaining their integrity. Its unique properties make it an essential component in modern packaging solutions.

What is Aluminum Blister Adhesive?

Aluminum blister adhesive refers to a type of adhesive specifically formulated for use with aluminum blister packs. These adhesives are engineered to create strong bonds between aluminum and other materials, such as PVC or PET, which are commonly used in pharmaceutical packaging. The formulation often includes resins and additives that enhance adhesion while offering resistance to moisture and temperature variations.

Applications in Pharmaceutical Packaging

The primary application of aluminum blister adhesive lies in pharmaceutical packaging, where it plays a crucial role in protecting sensitive medications from environmental factors such as light, moisture, and air. This type of packaging not only helps maintain the efficacy of drugs but also ensures compliance with safety standards by providing tamper-evident features. Furthermore, aluminum blister packs are favored for their ability to extend shelf life and improve patient adherence by allowing easy access to individual doses.

Benefits of Using Aluminum Blister Adhesive

Using aluminum blister adhesive offers numerous advantages that make it a preferred choice for manufacturers and consumers alike. One significant benefit is its excellent barrier properties, which help protect products from contamination and degradation over time. Additionally, the strong bonding capabilities ensure that the packaging remains intact throughout its lifecycle, reducing waste due to damaged goods and enhancing overall product safety.

Top Water-Based Resin Solutions

Chemix has developed a standout product that caters to the specific needs of manufacturers seeking reliable adhesion without compromising on safety or environmental standards. With a focus on performance, Chemix's water-based resin solution is designed to enhance the efficiency of aluminum blister adhesive applications.

Introduction to Chemix's Water-Based Resin Solution

Chemix's water-based resin solution is engineered for optimal bonding in various packaging scenarios, especially where aluminum blister adhesive is involved. This innovative adhesive formulation provides excellent adhesion properties while remaining safe and easy to use. The result? A seamless application process that supports both efficiency and sustainability in packaging operations.

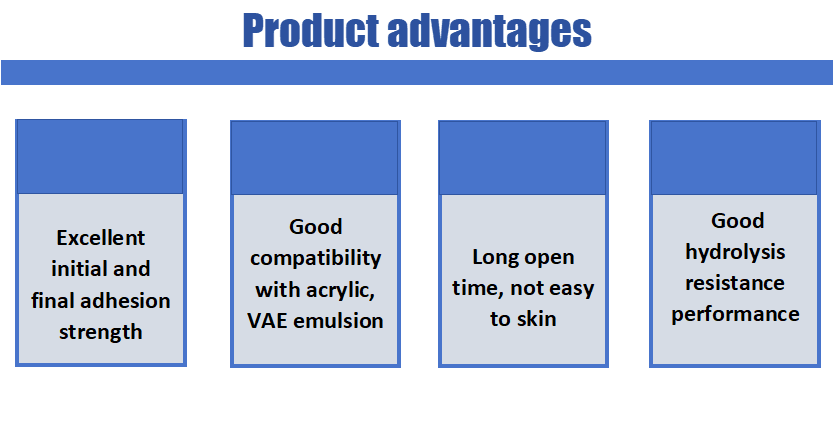

Advantages of Water-Based Resins

One of the primary advantages of water-based resins is their reduced environmental impact compared to solvent-based alternatives. These adhesives are typically low in volatile organic compounds (VOCs), making them safer for both users and the environment while still providing strong bonds necessary for aluminum blister adhesive applications. Additionally, they offer quick drying times and excellent flexibility, ensuring that packaged products remain secure even under varying conditions.

Another benefit lies in their ease of cleanup; since they are water-soluble, any spills or excess can be cleaned up with just soap and water—no harsh chemicals required! This feature not only simplifies maintenance but also reduces potential hazards associated with traditional solvent-based adhesives. Ultimately, using Chemix’s water-based resin solutions means you can achieve high performance without compromising on safety or sustainability.

Ideal Uses for Water-Based Adhesives

Water-based adhesives shine in various applications beyond just aluminum blister adhesive setups; they are incredibly versatile! Their ideal uses include packaging materials like paperboard cartons, labels, and flexible films where quick bonding and flexibility are paramount. Moreover, they excel in industries such as food packaging—where safety standards are stringent—and consumer goods where eco-friendly practices resonate with customers.

In particular, when paired with aluminum blister adhesive systems for pharmaceuticals, these resins ensure that products remain well-protected while being easy to open when needed by consumers. The combination not only enhances user experience but also reinforces brand integrity through quality packaging solutions that reflect responsible manufacturing practices. As more companies seek sustainable options without sacrificing performance or reliability, Chemix’s water-based resin solution stands out as an exemplary choice.

Comparing Solvent-Based vs. Water-Based Adhesives

Each type has its own unique characteristics that can significantly impact performance, especially for applications like aluminum blister adhesive in pharmaceutical packaging. Understanding these differences is crucial for making informed decisions about which adhesive to use.

Key Differences Explained

The primary distinction between solvent-based and water-based adhesives lies in their composition and drying mechanisms. Solvent-based adhesives contain organic solvents that evaporate as the adhesive cures, while water-based adhesives use water as the primary solvent, making them more environmentally friendly. This fundamental difference affects not only the application process but also factors like drying time, adhesion strength, and resistance to environmental conditions.

In terms of application environments, aluminum blister adhesive often benefits from specific properties offered by each type of adhesive. For instance, solvent-based adhesives may provide stronger initial bonding on certain surfaces compared to their water-based counterparts. However, this strength comes at the cost of longer drying times and potential environmental concerns associated with volatile organic compounds (VOCs) found in solvents.

Pros and Cons of Each Type

Solvent-based adhesives boast several advantages such as superior bonding strength and versatility across various materials. They are particularly effective for high-demand applications where durability is paramount—think aluminum blister adhesive used for pharmaceuticals that require tamper-proof packaging solutions. However, they also have drawbacks; their strong fumes can pose health risks during application and they may require special ventilation measures.

On the flip side, water-based adhesives are generally safer to work with due to lower VOC levels and reduced toxicity levels—making them a favorite among eco-conscious companies looking for sustainable options in packaging solutions like aluminum blister adhesive. While they might not always match the sheer strength of solvent types initially, advances in formulation technology have significantly improved their performance over time. The trade-off often lies in longer curing times which could affect production speeds.

Which One is Right for You?

Choosing between solvent-based and water-based adhesives largely depends on your specific needs and preferences when it comes to packaging requirements such as aluminum blister adhesive applications. If you prioritize strong adhesion under challenging conditions or are working with diverse substrates, a solvent-based option may be your best bet despite its environmental considerations. Conversely, if sustainability is high on your agenda or you're operating in a less demanding environment where safety is paramount, then a high-quality water-based adhesive could be your ideal solution.

Ultimately, understanding how each type aligns with your operational goals will help you make an informed choice that enhances both product integrity and consumer safety—especially important when dealing with sensitive items packaged using aluminum blister adhesive.

Specialty Adhesives for Unique Packaging Needs

When it comes to packaging, one size does not fit all. Specialty adhesives are designed to meet the unique demands of various applications, ensuring that products are securely packaged and preserved. From high-temperature environments to pressure-sensitive applications, these adhesives offer tailored solutions that can enhance product performance.

High-Temperature Adhesives

High-temperature adhesives are engineered for environments where heat is a critical factor. These adhesives maintain their bonding strength even when exposed to elevated temperatures, making them ideal for industries such as automotive and aerospace, where aluminum blister adhesive might be needed in conjunction with other materials. This type of adhesive ensures that packaging remains intact under stress, preventing leaks or product degradation.

In pharmaceutical packaging, high-temperature adhesives can also play a vital role in maintaining the integrity of aluminum blister adhesive seals during sterilization processes. By choosing the right high-temperature adhesive, manufacturers can ensure that their products withstand extreme conditions without compromising quality or safety. Ultimately, investing in these specialized solutions can lead to greater efficiency and reliability in packaging operations.

Pressure-Sensitive Adhesives

Pressure-sensitive adhesives (PSAs) are versatile and user-friendly options that require no heat or solvent activation for bonding. They adhere firmly upon contact with surfaces, making them perfect for labels and flexible packaging applications where aluminum blister adhesive might not be suitable due to its rigidity. The convenience of PSAs allows for quick application and repositioning without leaving residue behind.

In addition to their ease of use, pressure-sensitive adhesives offer excellent durability across various environmental conditions—ideal for products that need to withstand moisture or temperature fluctuations. Their ability to create strong bonds on a range of substrates makes them invaluable in many industries beyond pharmaceuticals, including food packaging and consumer goods. When considering your packaging needs, PSAs could be the go-to solution if you seek flexibility without sacrificing performance.

Innovations in Blister Packaging Adhesives

The world of blister packaging is constantly evolving with innovative adhesive technologies aimed at improving functionality and sustainability. New formulations are being developed that enhance the performance of aluminum blister adhesive while reducing environmental impact—perfect for companies looking to align with eco-friendly practices without compromising on quality. These innovations often include bio-based materials or water-based systems that provide effective bonding while minimizing harmful emissions during production.

Furthermore, advancements in adhesion science have led to improved formulations specifically designed for challenging surfaces or unique product shapes found in modern retail environments. Manufacturers now have access to specialty aluminum blister adhesives that cater precisely to these needs—ensuring optimal sealing properties while maintaining aesthetic appeal on store shelves. Staying ahead of these trends allows businesses not only to meet current market demands but also prepares them for future challenges in an ever-changing landscape.

Best Practices for Applying Blister Packaging Adhesives

When it comes to using aluminum blister adhesive, the application process can make or break your packaging project. Proper preparation and technique are vital for achieving a strong, reliable bond that meets your product's needs. Let’s dive into some best practices that will ensure your aluminum blister adhesive performs at its best.

Surface Preparation Tips

Surface preparation is the unsung hero of effective bonding with aluminum blister adhesive. Begin by ensuring that all surfaces are clean and free from dust, grease, or moisture; any contaminants can compromise adhesion and lead to failure down the line. It’s advisable to use solvents or cleaners specifically designed for this purpose, as they will help create an ideal surface for the adhesive to grip onto.

Additionally, roughening the surface slightly can enhance adhesion; think of it as giving your aluminum blister adhesive a textured playground to latch onto! This method increases surface area and provides better mechanical bonding. Don't forget to allow any cleaning solutions to dry completely before applying your adhesive—patience pays off!

Application Techniques for Optimal Bonding

Applying aluminum blister adhesive isn't just about slapping it on; technique matters! First, ensure you apply an even coat of adhesive across the surface—too much can lead to oozing and messiness, while too little may not provide adequate bonding strength. Using a roller or brush helps achieve uniform coverage, so choose your tool wisely based on the size of your project.

Next up is timing: once you've applied the aluminum blister adhesive, you’ll want to assemble the components quickly before the adhesive begins curing. This ensures maximum bond strength and reduces chances of misalignment—a nightmare in packaging! Finally, consider using clamps or weights during curing if possible; these will help maintain pressure on bonded surfaces until full strength is achieved.

Troubleshooting Common Adhesive Issues

Even with careful preparation and application techniques, issues can arise when working with aluminum blister adhesives—don’t panic! One common issue is inadequate bonding strength; if this happens, double-check that surfaces were properly cleaned and prepared before applying the adhesive again.

Another problem could be bubbling or wrinkling in the packaging after application; this often indicates too much moisture trapped under the surface during curing. If you notice this happening frequently, reassess your drying conditions—adequate ventilation can work wonders here!

Lastly, if you're facing issues with curing time taking longer than expected, consider environmental factors like temperature and humidity—they play a significant role in how quickly adhesives set up! Adjusting these conditions may save you from future headaches.

Conclusion

In the world of packaging, the choice of adhesive can make or break your product's success. Whether you're dealing with aluminum blister adhesive or exploring water-based options, understanding your needs is crucial. The right adhesive not only enhances functionality but also ensures that your packaging stands out on the shelves.

Choosing the Right Adhesive for Your Items

Aluminum blister adhesive is often favored in pharmaceutical settings due to its excellent barrier properties and ability to secure sensitive products effectively. However, if sustainability is a priority for your brand, you might lean towards eco-friendly alternatives that still deliver exceptional performance.

The Future of Eco-Friendly Adhesives

As consumers become more environmentally conscious, the demand for eco-friendly adhesives is on the rise. Innovations in formulations are paving the way for alternatives that maintain high performance while minimizing environmental impact—think water-based solutions and biodegradable options. Embracing these advancements not only aligns with consumer preferences but also demonstrates a commitment to sustainability in packaging practices.

Making Informed Packaging Decisions

Navigating through various types of adhesives can be overwhelming, but informed choices lead to successful outcomes. Consider factors like adhesion strength, drying time, and environmental conditions when selecting aluminum blister adhesive or any other type. By doing thorough research and testing different options, you can ensure that your packaging not only protects its contents but also resonates with your target audience.