Introduction

In today's fast-paced world, the versatility of PET plastic has made it a staple in various industries, from automotive to electronics. Understanding PET plastic applications is crucial for businesses looking to leverage its benefits effectively. With its lightweight nature and durability, PET serves as an ideal substrate for innovative adhesive solutions that enhance product performance.

Understanding PET Plastic Applications

PET, or polyethylene terephthalate, is widely used due to its excellent strength-to-weight ratio and resistance to impact and moisture. This makes it a popular choice for packaging, textiles, and even automotive components. By comprehensively understanding these applications, businesses can make informed decisions about the best bonding and gluing plastic techniques to utilize.

Importance of Adhesive Solutions

Adhesive solutions play a pivotal role in ensuring the integrity and longevity of products made from PET plastic. The right adhesive not only enhances bonding strength but also contributes to overall product performance by resisting environmental factors such as temperature fluctuations and humidity. As industries continue to innovate, finding effective pet glue options becomes increasingly important for maintaining quality standards.

Overview of PET Adhesives in Various Industries

The use of PET adhesives spans across multiple sectors including automotive manufacturing, electronics assembly, and home appliances. Each industry requires specific adhesive properties tailored to their unique challenges—whether it's dealing with heat resistance in vehicles or moisture resistance in electronics. An overview of these diverse applications showcases how essential adhesive solutions for PET plastic are in driving innovation across various fields.

The Role of PET Adhesive Film

In the world of adhesive solutions, PET adhesive film stands out as a versatile and efficient option for bonding and gluing plastic materials. This specialized film is made from polyethylene terephthalate (PET), a strong and durable thermoplastic that provides excellent adhesion properties across various applications. As industries increasingly seek reliable bonding solutions, understanding the role of PET adhesive film becomes crucial.

What is PET Adhesive Film?

PET adhesive film is a thin layer of adhesive material that utilizes the unique properties of polyethylene terephthalate to create strong bonds between surfaces. This type of pet glue is engineered to provide excellent adhesion while maintaining flexibility and durability, making it ideal for various applications. With its clear appearance, PET adhesive film can be seamlessly integrated into products without compromising aesthetics.

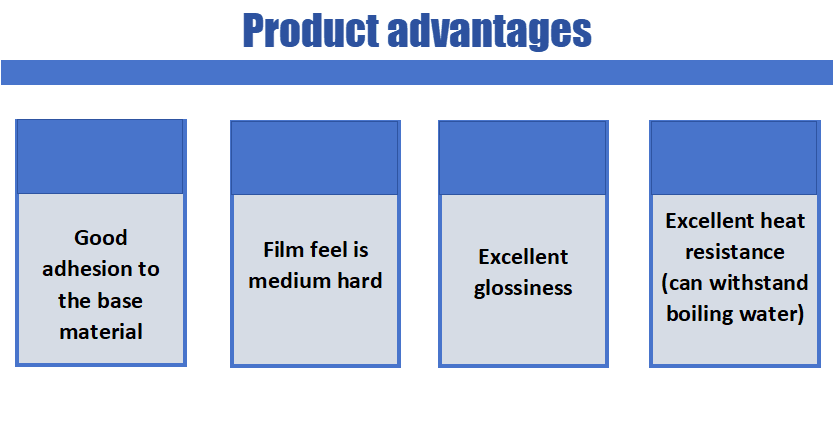

Key Benefits for Different Industries

One of the primary benefits of using PET adhesive film is its exceptional temperature resistance, which makes it suitable for demanding environments like automotive manufacturing and electronics. Additionally, this pet glue offers superior chemical resistance, ensuring that bonds remain intact even when exposed to harsh substances. Industries benefit from its ease of application; whether through lamination or direct bonding, manufacturers can streamline their processes with efficient adhesive solutions for PET plastic.

Applications in Automotive Manufacturing

In automotive manufacturing, PET adhesive film plays a critical role in assembling components such as dashboards, trims, and insulation materials. The strength provided by this type of pet glue ensures that parts remain securely bonded under extreme conditions like vibrations and temperature fluctuations common in vehicles. Furthermore, using PET adhesives enhances safety by reducing the risk of component failure during operation, making it an essential choice for manufacturers aiming to meet rigorous industry standards.

Innovative PET Glue Solutions

In the ever-evolving world of adhesives, innovative PET glue solutions are paving the way for enhanced performance and versatility. The demand for effective bonding and gluing plastic has led to the development of advanced technologies that cater to various industrial needs. By leveraging these innovations, manufacturers can achieve stronger, more durable bonds while also addressing sustainability concerns.

Exploring Adhesive Technologies

The landscape of adhesive technologies is vast and varied, especially when it comes to PET adhesive film applications. From thermosetting to thermoplastic adhesives, each type offers unique benefits tailored to specific requirements in different industries. As we explore these technologies, it's clear that advancements are continually being made, allowing for better adhesion properties and improved long-term performance in bonding and gluing plastic products.

One notable trend is the shift towards hybrid adhesive systems that combine multiple properties for enhanced effectiveness. These systems often integrate traditional bonding methods with new-age materials, resulting in superior adhesion capabilities. This evolution is crucial for industries like automotive and electronics where durability and reliability are paramount.

Chemix's Water-Based Resin Solution

Among the innovative solutions making waves in the PET glue market is Chemix's water-based resin solution specifically designed for adhesive applications with PET plastic. This solution stands out not only due to its exceptional bonding strength but also because it aligns with modern environmental standards by minimizing harmful VOC emissions. By choosing this option, manufacturers can ensure effective adhesion while contributing positively to sustainability efforts.

Chemix’s water-based resin is particularly effective in various applications where traditional solvents might pose risks or limitations. Its formulation allows for quick curing times without compromising bond integrity, making it ideal for high-speed manufacturing environments. With such advantages, this solution exemplifies how innovation can meet both performance needs and environmental responsibility.

Environmentally Friendly Bonding Options

As industries become increasingly aware of their environmental impact, environmentally friendly bonding options have gained significant traction within adhesive solutions for PET plastic applications. Innovations such as bio-based adhesives and low-VOC formulations are redefining what it means to bond effectively without harming our planet. These green alternatives not only reduce ecological footprints but also appeal to consumers who prioritize sustainability in their purchasing decisions.

Moreover, adopting eco-friendly adhesive solutions can enhance a brand’s reputation by showcasing a commitment to responsible manufacturing practices. Companies that invest in such innovations often find themselves ahead of competitors who may still rely on traditional methods laden with harmful chemicals or processes that contribute negatively to the environment. In an era where corporate social responsibility matters immensely, choosing sustainable options like these represents a smart business strategy.

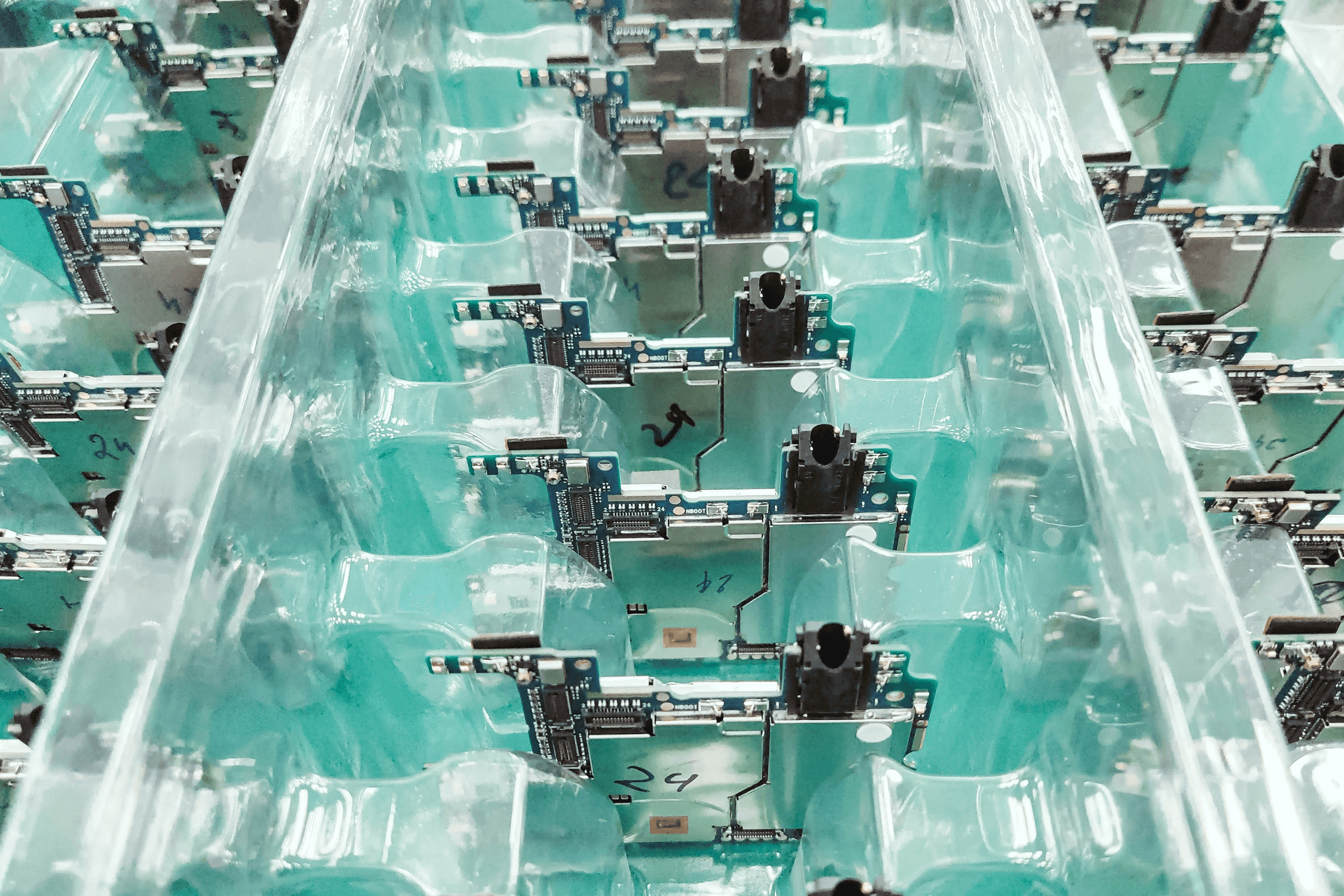

Bonding and Gluing Plastic in Electronics

In the fast-paced world of electronics, the importance of strong adhesive solutions cannot be overstated. Devices are becoming sleeker and more compact, leading to increased reliance on effective bonding and gluing plastic components together. A robust adhesive not only ensures that parts stay together but also plays a vital role in protecting sensitive internal components from environmental factors.

Importance of Strong Adhesive for Electronics

Electronics are often subjected to various stresses such as heat, vibration, and moisture, making strong adhesives essential for long-lasting performance. The right pet glue can provide the necessary strength to withstand these challenges while maintaining the integrity of the device's design. Additionally, a reliable adhesive solution helps prevent failures that could arise from weak bonds, ultimately enhancing user satisfaction.

Commonly Used PET Adhesives in Electronics

When it comes to bonding and gluing plastic in electronics, several types of PET adhesives stand out in the market. These include PET Adhesive Films known for their exceptional clarity and flexibility, making them ideal for applications requiring aesthetic appeal without compromising functionality. Other commonly used options are water-based adhesives that offer excellent adhesion properties while being environmentally friendly—perfect for eco-conscious manufacturers looking to reduce their carbon footprint.

Ensuring Durability and Performance

To ensure durability and performance in electronic devices, selecting high-quality adhesive solutions for PET plastic is crucial. Manufacturers must consider factors like temperature resistance, chemical stability, and moisture resistance when choosing a pet glue or adhesive film. By focusing on these aspects during the selection process, companies can produce electronics that not only perform well but also last longer under various conditions.

Automotive Adhesive Solutions

In the automotive industry, adhesive solutions play a pivotal role in vehicle assembly, ensuring that components are securely bonded while maintaining performance and safety. As vehicles become more advanced and lightweight, the need for reliable bonding materials like PET glue and PET Adhesive Film has surged. These adhesive solutions for PET plastic not only enhance structural integrity but also contribute to overall vehicle efficiency.

Critical Role in Vehicle Assembly

The assembly of modern vehicles relies heavily on strong and durable adhesives, particularly when it comes to bonding and gluing plastic components. PET glue is increasingly favored for its ability to create robust bonds that withstand environmental stresses such as heat, moisture, and vibration. This critical role in vehicle assembly ensures that parts remain intact during operation, ultimately enhancing the longevity of the vehicle.

Specialty Adhesives for PET in Automotive

Specialty adhesives designed specifically for PET applications are revolutionizing how automotive manufacturers approach bonding challenges. These adhesives provide unique properties such as flexibility, resistance to chemicals, and excellent adhesion to various substrates. Utilizing PET Adhesive Film allows manufacturers to streamline their processes while ensuring high-quality bonds between different materials used in car interiors and exteriors.

Enhancing Performance and Safety

Adhesive solutions for PET plastic not only improve performance but also significantly enhance safety features in vehicles. Stronger bonds created by innovative pet glue formulations reduce the risk of component failure during critical driving conditions. As manufacturers continue to prioritize safety alongside performance, the demand for effective bonding and gluing plastic solutions will only increase.

Home Appliances and PET Adhesives

The use of PET adhesives in home appliances has surged due to their exceptional bonding capabilities and versatility. These adhesive solutions for PET plastic provide manufacturers with the reliability needed to create durable, long-lasting products. From refrigerators to washing machines, PET adhesive film plays a crucial role in ensuring that components remain securely attached, even under varying conditions.

Reasons for PET Use in Home Appliances

One of the primary reasons for using PET in home appliances is its remarkable strength-to-weight ratio. This lightweight material not only reduces the overall weight of appliances but also enhances energy efficiency during transportation and usage. Additionally, the chemical resistance of PET makes it an ideal choice for appliances that may come into contact with various cleaning agents or environmental factors.

Another factor contributing to the popularity of PET adhesives is their excellent thermal stability, which is essential for appliances that operate at high temperatures. This characteristic ensures that bonding and gluing plastic components maintain their integrity over time, reducing the risk of failure or damage. Furthermore, with consumer preferences leaning towards sustainable options, using recyclable materials like PET aligns perfectly with eco-friendly initiatives.

Efficient Bonding Solutions for Appliances

Its superior adhesion properties allow manufacturers to bond different materials seamlessly without compromising performance or aesthetics. Moreover, advancements in technology have led to innovative formulations of adhesive solutions specifically designed for high-stress applications within household devices.

PET adhesive film offers flexibility during manufacturing processes by allowing easy application on various surfaces while maintaining strong bonds throughout a product's lifecycle. This adaptability is particularly beneficial when dealing with complex shapes or multi-material assemblies commonly found in modern appliances. As a result, manufacturers can achieve both functional and visually appealing designs without sacrificing durability.

In addition to performance benefits, these adhesives also contribute positively to production efficiency and cost-effectiveness by reducing assembly times and minimizing waste during manufacturing processes. By streamlining operations through effective bonding techniques, companies can focus on innovation while ensuring product quality remains uncompromised.

Future Trends in Home Appliance Adhesives

Looking ahead, several trends are emerging within the realm of home appliance adhesives that could reshape how we view bonding and gluing plastic components. One significant trend is the push towards sustainability; manufacturers are increasingly seeking eco-friendly adhesive solutions that not only perform well but also minimize environmental impact throughout their lifecycle—think water-based formulations or bio-based options.

Additionally, smart technology integration into home appliances opens new avenues for adhesive applications—think about how sensors or displays might require specialized bonding techniques using advanced pet glue formulations tailored for electronic components within these devices! The demand for multifunctional adhesives capable of providing both structural integrity and additional features will likely rise as smart homes become more prevalent.

Lastly, as consumers continue prioritizing energy efficiency and durability in their choices of household items, there will be an ongoing need for research into enhanced properties within existing adhesive solutions—ensuring they meet evolving standards while remaining competitive in terms of pricing!

Conclusion

As we wrap up our exploration of PET adhesives, it’s clear that the future holds exciting innovations in this realm. With advancements in technology, we can expect new formulations of PET glue that enhance performance and versatility across various applications. The ongoing research and development efforts promise to yield even more effective adhesive solutions for PET plastic, ensuring they meet the evolving demands of industries.

The Future of PET Adhesive Innovations

Looking ahead, the potential for PET adhesive film is boundless. Innovations such as smart adhesives that respond to environmental changes or pressure-sensitive options will revolutionize how we bond materials. As industries continue to seek lighter and stronger alternatives, the evolution of adhesive solutions for PET plastic will play a pivotal role in manufacturing efficiency and product longevity.

Emphasizing Sustainability in Adhesives

Sustainability is becoming a cornerstone in adhesive development, with a growing emphasis on eco-friendly materials. Manufacturers are increasingly focusing on creating PET glue options that minimize environmental impact while maintaining strong bonding capabilities. By prioritizing sustainable practices, the industry not only addresses ecological concerns but also appeals to consumers who value environmentally responsible products.

Final Thoughts on Adhesive Solutions for PET Plastic

In conclusion, the landscape of bonding and gluing plastic is rapidly changing as innovative technologies emerge. The versatility and effectiveness of PET adhesive film make it an essential component across multiple sectors, from automotive to electronics and home appliances. As we move forward, embracing these advancements will ensure that adhesive solutions for PET plastic not only meet current needs but also pave the way for a sustainable future.