Introduction

In the world of crafting, construction, and everyday repairs, the importance of bonding right cannot be overstated. The strength and durability of your projects hinge on selecting the appropriate adhesive for the job. Whether you’re using hot glue glue for a quick fix or epoxy adhesive glue for a more permanent solution, understanding your options can save you time and frustration.

The Importance of Bonding Right

Choosing the right adhesive is crucial not just for achieving a strong bond but also for ensuring that your materials work harmoniously together. When done correctly, bonding can enhance the longevity and functionality of your projects. Adhesive experts often emphasize that one small misstep in adhesive selection can lead to catastrophic failures down the line.

Understanding Different Adhesives

There’s an array of adhesives available today, each with its unique properties and applications. Hot melt adhesive is perfect for quick fixes and crafts, while epoxy resin adhesive offers exceptional strength for structural applications. On the other hand, cyanoacrylate glue is known for its rapid curing time, making it ideal when time is of the essence.

Common Bonding Mistakes to Avoid

Even seasoned DIY enthusiasts can fall prey to common bonding mistakes that could compromise their projects' integrity. One frequent error is neglecting surface preparation; without proper cleaning or roughening up smooth surfaces, even the best epoxy adhesive may fail to adhere effectively. Moreover, failing to test compatibility between materials before application can lead to disastrous results—something no one wants after investing time and effort into a project.

Choosing the Right Adhesive

With a plethora of options available, understanding the unique characteristics of various adhesives is crucial. Whether you're a DIY enthusiast or a seasoned professional, knowing which adhesive to use will elevate your craftsmanship and ensure lasting results.

Exploring Hot Glue Variants

Hot glue is often the go-to for quick fixes and creative projects, but did you know there are several variants? From low-temperature hot melt adhesive designed for delicate materials to high-temperature options that bond heavier items, each type serves its own purpose. Adhesive experts often recommend experimenting with different hot glue formulations to find the perfect match for your specific needs.

The versatility of hot glue is one of its biggest selling points; it can bond wood, fabric, plastic, and even metal in some cases. However, remember that while hot glue provides a strong initial bond, it may not hold up under extreme conditions or heavy loads over time. So if you're looking for something more permanent or robust, you might want to consider alternatives like epoxy adhesive.

Why Epoxy Adhesive Rules

Epoxy adhesive reigns supreme when it comes to creating strong and durable bonds across a variety of materials. Its two-part system—resin and hardener—creates an incredibly tough bond that can withstand heat, moisture, and stress better than most other adhesives on the market. This makes epoxy resin adhesive ideal for applications ranging from home repairs to industrial uses.

One key advantage of using epoxy adhesive glue is its ability to fill gaps between surfaces effectively while curing into a solid mass that enhances structural integrity. Additionally, epoxy's resistance to chemicals means it's perfect for environments where exposure could weaken other adhesives like hot melt adhesive or cyanoacrylate glue. If you’re serious about bonding strength and longevity in your projects, epoxy should be at the top of your list.

The Surprising Power of Cyanoacrylate Glue

Often referred to as super glue, cyanoacrylate glue packs quite a punch despite its small size! This fast-acting adhesive creates an incredibly strong bond almost instantly upon contact with moisture—a feature that makes it particularly useful in emergency repairs or intricate crafting tasks where precision is key. Adhesive experts frequently recommend cyanoacrylate when time is of the essence but caution against using it on porous materials since it may not provide optimal adhesion.

What’s more surprising about cyanoacrylate glue is its versatility; it works well on plastics, ceramics, rubber, and even some metals! However, keep in mind that this type of adhesive isn't ideal for larger surface areas due to its rapid setting time—once it's bonded; there's no going back! For those who appreciate speed without compromising strength in smaller applications, cyanoacrylate certainly deserves consideration alongside traditional options like epoxy adhesive.

Surface Preparation Matters

Without properly preparing the surfaces, even the most reliable adhesive—be it hot glue or epoxy adhesive—can fail to deliver a strong bond. Adhesive experts often emphasize that investing time in this step can save you from future headaches and ensure your projects stand the test of time.

Cleaning and Drying Surfaces

First up on the surface preparation checklist is cleaning and drying those surfaces like a pro! Dust, grease, or moisture can sabotage any attempt at bonding, making even high-quality epoxy resin adhesive ineffective. Use a suitable cleaner for your materials—whether it's rubbing alcohol for plastics or soapy water for wood—and make sure everything is completely dry before applying your chosen adhesive contact glue.

Roughing Up Smooth Surfaces

Smooth surfaces might look sleek, but they can be a nightmare when it comes to adhesion. To give your hot melt adhesive or cyanoacrylate glue a fighting chance, consider roughing up those slick areas with sandpaper or a file. This simple technique creates tiny grooves that increase surface area and enhance mechanical interlocking, leading to stronger bonds with your epoxy adhesive glue.

Testing Compatibility of Materials

Not all materials are created equal; some may not play nice together when you try to bond them using your favorite adhesives. That's where testing compatibility comes into play—a crucial step often overlooked by DIY enthusiasts! Before committing to that beautiful project, apply a small amount of your chosen adhesive (whether it's hot glue or epoxy) on an inconspicuous area and see how they react; this will save you from potential disasters down the line.

Application Techniques for Success

Whether you're wielding hot melt adhesive, epoxy adhesive glue, or even cyanoacrylate glue, understanding the nuances of application is crucial. This section will cover when to use each type of adhesive and how to apply them effectively for the best results.

When to Use Hot Melt Adhesive

Hot melt adhesive is your go-to when you need a quick bond that sets rapidly. It's perfect for projects that require immediate handling, such as crafts or light repairs around the house. However, be mindful of its limitations; hot glue may not hold up under extreme temperatures or heavy loads, making it essential to consult with adhesive experts when in doubt.

To achieve optimal results with hot melt adhesive, ensure your surfaces are clean and dry before application. Apply it in a steady motion to avoid clumps or uneven layers—after all, nobody wants their project looking like it's been through a glue factory explosion! And remember: while hot glue bonds quickly, patience is still key; give it adequate time to cool and set before putting any stress on the joint.

Perfecting Epoxy Adhesive Glue Application

Epoxy adhesive glue is known for its strength and versatility—it’s the superhero of adhesives! When using epoxy resin adhesive, make sure to mix your components thoroughly according to package instructions; this ensures maximum bonding power. The application process can be messy if you’re not careful; so keep some paper towels handy for any accidental spills.

For best results, apply epoxy in thin layers rather than globbing it on like frosting on a cake—less is often more here! Use clamps or weights if possible while curing; this will help maintain pressure on the bond as it sets and significantly enhance durability. And don’t forget: curing times vary depending on temperature and humidity levels—so check those conditions before diving into your project!

Mastering Adhesive Contact Glue

Adhesive contact glue requires finesse but offers incredible strength once mastered! This type of adhesive works best when both surfaces are coated and allowed to dry before pressing them together—think of it like two dance partners waiting for just the right moment to connect. The result? An unbreakable bond that will stand up against time!

To ensure success with contact glue application, start by applying an even layer on both surfaces without over-saturating them (nobody likes soggy cardboard!). After allowing them to dry until tacky (usually about 10-15 minutes), carefully align and press them together firmly without sliding them around—this isn’t a game of Twister! Once bonded, give yourself a pat on the back—you’ve just mastered one of the toughest techniques in bonding!

Curing and Bonding Times

Each type of adhesive has its unique characteristics that dictate how long you need to wait for a strong bond. Whether you're using hot glue glue, epoxy adhesive, or cyanoacrylate glue, knowing the right timing is crucial for achieving optimal results.

Understanding Epoxy Resin Adhesive Curing

Epoxy resin adhesive curing is a fascinating process that transforms a liquid into a solid bond through chemical reactions. Typically, epoxy adhesive glue requires a specific mix ratio of resin and hardener, so precision is key here—too much or too little can lead to weak bonds. Once mixed, the curing process can take anywhere from minutes to hours depending on the formulation; some quick-setting epoxies are ready in under 30 minutes while others may take up to 24 hours for full strength.

Timing for Hot Glue Bonds

Hot melt adhesive is known for its fast application and quick setting times, making it a favorite among DIY enthusiasts and professionals alike. Generally, hot glue bonds can set within seconds but may not reach their full strength immediately; it's advisable to allow at least 10 minutes before putting any stress on the bond. However, keep in mind that while hot glue provides immediate hold, it may not be suitable for high-stress applications compared to epoxy adhesive options.

Importance of Patience in Bonding

The importance of patience in bonding cannot be overstated—rushing the process often leads to disappointment down the line! Whether you're using epoxy resin adhesive or an adhesive contact glue, taking time to allow proper curing will pay off with stronger bonds that stand the test of time. Remember that good things come to those who wait; your project deserves that extra bit of TLC from you!

Eco-Friendly Options in Adhesives

In today's world, the demand for eco-friendly options in adhesives has grown tremendously. As consumers become more conscious of their environmental impact, the adhesive industry is stepping up to provide sustainable solutions. From hot glue glue to epoxy adhesive, there are now numerous alternatives that are both effective and environmentally friendly.

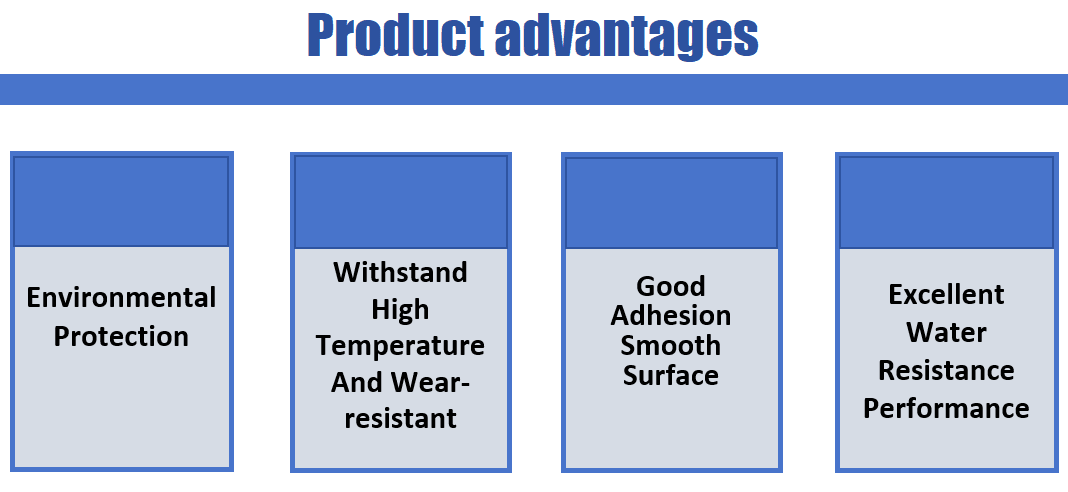

Benefits of Chemix's Water-Based Resin Solution

Chemix's water-based resin solution is a game changer in the adhesive market. This innovative product offers strong bonding capabilities comparable to traditional epoxy adhesive glue while being significantly less harmful to the environment. Adhesive experts praise its low VOC (volatile organic compounds) content, making it safer for indoor use and reducing air pollution.

Moreover, this water-based solution is versatile enough for various applications, from crafts to industrial uses. Unlike hot melt adhesive that can emit fumes during application, Chemix’s product provides a safer alternative without compromising on performance. By choosing such eco-friendly options, consumers contribute to a healthier planet while enjoying reliable bonding solutions.

Sustainable Practices with Adhesive Products

Sustainability doesn't just stop at choosing the right product; it extends into how we use adhesives as well. Many adhesive experts advocate for responsible usage practices that minimize waste and promote recycling of packaging materials associated with adhesives like cyanoacrylate glue and epoxy resin adhesive. Simple steps such as using only what you need can significantly reduce excess waste.

Additionally, manufacturers are increasingly adopting sustainable practices by sourcing raw materials responsibly and utilizing recyclable packaging for their products. For instance, some companies are exploring biodegradable formulations that break down naturally over time instead of lingering in landfills indefinitely like traditional adhesives might do. By supporting these initiatives, consumers can help drive change towards more eco-conscious bonding methods.

The Future of Eco-Conscious Bonding

The landscape of adhesives is rapidly evolving towards sustainability thanks to innovations in chemistry and consumer demand for greener products. As we look ahead, it's clear that the future will likely see more advanced formulations like bio-based epoxy adhesive options that retain high performance while being kind to our planet. Adhesive experts predict an increase in research focused on developing renewable resources for creating effective bonding agents without compromising strength or durability.

Moreover, educational campaigns aimed at raising awareness about eco-friendly products will play a crucial role in guiding consumers toward making informed choices when selecting adhesives such as hot melt adhesive or contact glue alternatives. With ongoing advancements and increased consumer interest in sustainability, we can expect a thriving market filled with innovative solutions tailored for environmentally conscious bonding needs.

Conclusion

In the world of bonding, understanding the right techniques and materials can make all the difference. Whether you're wielding hot glue glue, epoxy adhesive glue, or cyanoacrylate glue, knowing when and how to use each type is crucial for achieving strong, lasting bonds. By keeping in mind the importance of surface preparation and application techniques, you can avoid common pitfalls that lead to disappointing results.

Key Takeaways for Effective Bonding

To ensure effective bonding, always choose the right adhesive for your project. Hot melt adhesive works wonders for quick fixes, while epoxy resin adhesive provides unmatched strength for more demanding applications. Don't forget about surface preparation; cleaning and roughening surfaces can significantly enhance adhesion quality.

Embracing Eco-Friendly Adhesives

As we become more environmentally conscious, embracing eco-friendly adhesives is not just a trend but a responsibility. Products like Chemix's water-based resin solution offer sustainable options without sacrificing performance compared to traditional adhesives like epoxy adhesive or cyanoacrylate glue. The future of bonding lies in balancing effectiveness with ecological mindfulness—making eco-friendly choices a win-win situation.

The Role of Adhesive Experts in Quality Bonding

When it comes to achieving optimal results in bonding projects, consulting with adhesive experts can provide invaluable insights. These professionals are well-versed in various products such as hot glue glue and adhesive contact glue and can guide you toward making informed decisions tailored to your specific needs. Their expertise ensures that whether you're using epoxy adhesive or cyanoacrylate glue, your projects will have the durability required to stand the test of time.